1/1/2015

guest I'm not convinced they don't know how to make them, because it really should not be difficult to make electric cars. The technology is not any harder than engines.

It's not so much that they don't know, it's all that other stuff about innovator's dilemma, being too big of a ship to right quickly, etc.

Someone linked this, possibly here, a little while ago, but everyone should watch this full talk by Marc Tarpenning Co-Founder Of Tesla About Starting Tesla (VIDEO) | CleanTechnica

It's like a year old or something, and it's long (over an hour?), but it's worth hearing what he's got to say about their relations with the auto industry and suppliers and such.�

1/1/2015

guest One of the things he's saying in that talk is that they don't have any electrical engineering competency left in house. The other huge competency they don't have is software. Actually, not much engineering is left, period, other than engines. They hollowed themselves out in the name of profits and supply chain efficiency, and they now have a floor of engine designers with a skyscraper of marketing and management on top.

Yeah, they don't know how to make them. Hell, they're full of people who for the longest time thought it was impossible to make them. And now, those who said it's impossible to do something are being replaced by those who are doing it.�

1/1/2015

guest Indeed, I listened to this a second time a couple of days ago. It's about the 53 minute mark that Tarpenning talks about his experience consulting at other automakers... basically says the one physical thing they do now is make engines.�

1/1/2015

guest One other thing. There is a huge difference between competence and creativity. Some of the brightest people I know in my field, when presented with a wild idea, will reflexively go through every reason why it cannot, should not, and will not be done. They are simply down-to-earth, reasonable people, who are also brilliant engineers. But technical brilliance combined with a conservative mindset doesn't lead to breakthrough innovation. On top of brilliant, you need to be a bit crazy, just as you have to be nuts to take on a huge and established auto industry that's been around for more than 100 years and accounts for 4% of the US GDP (while simultaneously taking on the defence industry, doing more impossible things).

If you were that kind of engineer, would you go to work for GM or Tesla? And if you went to work for GM, because they buried you in money (not that they would), would you get along well with the ones who are already there and "who've built this company and carried it through thick and thin from before you were born?"

Bob Lutz was a force of nature at GM, and when he saw Musk he understood immediately what was going on. He fought like mad to push through the Volt, and what did that do for his GM career? It ended it. I'm amazed Carlos Ghosn made it so far as the head of Renault/Nissan. Maybe they have a more enlightened board.

Even Panasonic doesn't get it. Or maybe they do, and they want to milk it for all it's worth? Time will tell. One thing I know for sure is that every time I hear how the big automakers will come in and eat Tesla's lunch once it's proven to be a lucrative market, I know I should buy more stock (only I can't, 'cause I'm already all in.)�

1/1/2015

guest Having built my own EV I'll agree with that statement, with a major caveat. Building an EV is easy, building a really great EV is not, because it's all related to the battery parameters and cost. Until the other OEM's approach the energy density and cost per kWh of Tesla they won't be able to build a compelling EV.�

1/1/2015

guest agreed- couple that with a SC network exclusive; and direct sales avoiding dealer costs and it's a really tough road for other mtgs�

1/1/2015

guest These are my thoughts exactly, it's odd to me how many people still don't get it. Analogously, we're in that phase where people were saying "but the market for touch screen phones is only 2% so iPhones will remain a niche product" and we all know how that played out with Apple holding 20%+ market share in most countries these days. For Tesla, they would only need a 1.5% of the $2T market to saturate three factories (Fremont, Asia, Europe).�

1/1/2015

guest I thought I would post link to the Randy Carlson's last October article that has slightly sarcastic take on the GM's calculus behind the ELR, just in case if some of you missed it. Looks like smile or two would be good for the fellow TMC members at this particular time...

Is Cadillac's ELR A Tesla Competitor? Maybe (TSLA) | Seeking Alpha�

1/1/2015

guest Elon responsibilities at SpaceX, SolarCity = Model X delay??

I wonder if I will be vilified for saying this here? Please object if I'm way off base....

Have you ever wondered if the release of Model X would have already occurred if Elon wasn't spread so thin? I've heard he spends the equiv of 2-3 days a week on Tesla. If he hasn't completely delegated the Model X project..... Is he slowing it down each week

"We currently expect to have production design Model X prototypes on the road by the end of 2014 and begin volume deliveries to customers in the spring of 2015."�

1/1/2015

guest Elon working more hours does not speed the development of Model X. He is not a designer and he is not on the engineering team.

Elon has slowed bringing the Model X to market by telling the design team and the engineering teams that their current proposal is not good enough and do a better job.

From what I can tell Elon is the big picture guy. Handles broad outlines of negotiations with third parties(Panasonic,Wall Street firms issuing Tesla convertible notes, MB buying battery packs), settles disagreements between executives inside Tesla, makes broad strategic decisions, sets broad goals for the company, makes outlines for product architecture, sometimes makes small decisions like Model S handles, and does a lot of public relations for the company.

But he does not actually do the nitty gritty of designing and engineering. That is what takes time. Elon is not indecisive.�

1/1/2015

guest Have you ever finished a portion of a project that cannot move forward until management reviews and gives approval? Since I've heard Elon is very particular about his cars being perfect I wonder if design and engineering are often waiting for his approval or input before moving onto next phase.�

1/1/2015

guest G.P.: My take on this has evolved to believe that there are three major reasons for the model X delay...in no particular order.

1. They do want to get it 'perfect'. They want the 5 star crash rating; CR to give it high ratings and another 'Car of the Year' award from Motor Trand (Insert other name if you like)

2. With one assembly line they can't make the model S fast enough to satisfy demand AND the profit margins on the S are getting better each quarter while the profit margins on the X initially probably won't be as high.

3. Battery constraint. Until this is somewhat resolved there is no point in introducing another vehicle.

While I think there is some pressure to release the X, I think it is mitigated by one or more of the issues above.

edit: #4: The Osborne (sp) Effect: As they move closer to the production date they will draw some sales from the S. Elon indicated that 2014 was a year o test the demand for the model S. He is testing the demand.�

1/1/2015

guest Yeah. The delay in almost certainly because resources have been slower to shift to the X program as they have been needed in S for longer than initially thought. There is no point on releasing the X as long as they are cell constrained. In fact there is no point in releasing the X as long as they are production constrained at all.

Elon hasn't said this. It would probably be bad PR to tell everyone on the waiting list, "your car is taking so long because we are dragging our feet on it as we sort out production constraints on the Model S. " Sounds much better to say they are just making the car extra perfect and awesome.�

1/1/2015

guest A positive review of the Mercedes B-Class, built with a Tesla powertrain, came out in the WSJ. We were talking earlier about why Tesla's competition sits on their collective bums while Tesla is preparing to eat their lunch, and how the innovator's dilemma is holding the incumbents back. They really have to be dragged into the future kicking and screaming, while their executives "are looking at their shoes."

The middle part of the article is really about Tesla. Here is a taste:

Link to the article (just skip the ad.)�

1/1/2015

guest I would be shocked to find Elon has to sign off everything. That's what managers are for. Elon gives his order: "Must be perfect". Manager interprets. If he's wrong, I suppose he could lose his job, but I betcha they pretty much know what Elon wants. After the huge amount of, shall we say, R*calls on the Model S Signatures for fit and finish, door handles, and putting in things that had not made it to the factory in time for your new car to be delivered (like the bits 'n' bobs cubby under the 17 inch screen), it seems only wise to make the Model X absolutely ready. There will be a lot more microscopic scrutiny and comment since Tesla will not get the leniency they got on their first model. It would be bad press to hear, that of every new model built, the first thousand or so would always be beta testers. Expectations have gone higher this round.�

1/1/2015

guest Even with Elon only working ~40-45hrs per week for Tesla I doubt engineering and design can work faster than he can review.

I heard him on CNBC say he used to work 100 hrs plus per week now it is a more manageable 80-90 hrs per week half spent on Tesla and half on SpaceX.�

1/1/2015

guest I hope you're correct. I wonder how often his reviews require him to physically see and touch the progress, enhancements, changes? That's hard to do when you're at SpaceX...... assuming the engineers are 400 miles away in Bay Area. Or do they work on the Model X at the Tesla office next to SpaceX in Hawthorne, CA.

of course what I am questioning may have had nothing to do with the Model X delays of, what is it now..... 18 mos?�

1/1/2015

guest Tesla Design is in Hawthorne within the SpaceX industrial park. That is what needs to be touched.

The last time I heard Elon talk about Model X delay he talked about design. He said getting a functional design in a CUV was easy and getting a beautiful design was easy. But getting both in a CUV was very difficulty. Also talked about the Falcon doors and making sure the seals hold up over many years of use.

I really don't think Elon needs to "touch" the engineering.

Tesla does have a Chief Technical Officer as well.

Once there are beta models I am sure they can ship them down to Hawthorne in a day or two.

Elon does not do all the "managing."�

1/1/2015

guest Really over reaching. Demonstrating your motives�

1/1/2015

guest Not so sure. tesla is not Ford. there are not hundreds of products. In essence there is one for sale and probably two in major development. While the small stuff I am sure is left to managers., some of the larger decisions I am sure are at times held up pending review. If I was the CEO And the success of tesla directly links with a paradigm shift in the way we travel not to mention the thousands of people I would be employing , you can bet I would want my hand in all the pies, before they were baked. I cannot remember the exact interview, but it was my impression some of the hold up is in fact due to while it met others standards it did not meet his.�

1/1/2015

guest I am assuming that, over time, Musk's standards are being absorbed and adopted by the people who work with him. I don't see how anyone would last too long on the team if that weren't the case.�

1/1/2015

guest I tend to agree with what you said to an extent. I would be surprised if Elon did not have a say in the final design, however I would also be surprised if the delays were due to him not being available. More likely the delays are due to trying to get every detail right.�

1/1/2015

guest Agreed...that is what I meant.�

1/1/2015

guest Here is what Elon said about X delay, quote from transcript below. It makes sense.

"Yes, there�s no question we�re delayed on the Model X, although that�s I wouldn�t say particularly new information. Relative to our earlier forecast, we had to spend a lot more time making sure we got the Model S right, and it took longer to get to some of the international markets and what not. So it just didn�t make sense for us to be focusing on Model X if we didn�t have our Model S house in order. I think we're in pretty good shape on the S front, so our focus is very heavily on the X, and just making sure it's a phenomenal product. And, we expect to be varying production cars roughly Q2 next year.

We'll have the production design articles, I guess beta articles or production-release candidates around the end of this year, but we want to make sure we've got a decent period of validation with those release-candidate vehicles, because the production ramp for Model X will be much greater than for S, so much deeper. So with S we have quite a shallow production ramp, start off real slow and as we encountered issues we were able to correct them without having a large number of cars in production on the roads.

With X it's going to be sharp ramp, which means we really need to make sure that we've properly validated issues and made sure in all temperatures and climates and road types that the car is really solid before ramping up production. Otherwise, we would risk having a recall or a bad customer experience."�

1/1/2015

guest I completely agree with you on #2 and #3. And I'll add in one more reason, Elon's incentive for 30% margins for 4 consecutive quarters. I think he might see a way to get this with Q3'14-Q2'15 so long as ModelX volume isn't too much in Q2'14. I doubt this is a major reason for the delay, battery constraint is probably the biggest single factor, but it could be something on his mind.

As a Tesla fan I want to see the Model X out ASAP, but as an investor it's just not a big deal to me right now.�

1/1/2015

guest In my opinion Tesla's delay of the Model X (ie., to Q2 of 2014) isn't an issue.

Tesla originally delayed the Model X since it made business sense. Not only could they focus on Model S scaling, service centers, stores, superchargers, etc but they could also make the Model X better by having more development time. Further, by delaying Model X to 2014 they could also smoothen out the production ramp of the S/X platform, so it's a smoother ramp until Gen3. This makes sense on most all fronts.

The main reason for Tesla's original delay of the Model X was because Model S demand was much greater than anticipated. This allowed them the opportunity to focus longer on the S. It also allows them to make the X better, and thus X sales will likely be higher than their original expectations.

Now I do think Model X slipped a few months further than their original delay, but that's because Tesla is in a position to allow that. It's fairly inconsequential if the Model X comes out in Q1 2014 or Q2 2014. The main reason it doesn't matter is because Tesla is still scaling Model S production and trying to meet demand.�

1/1/2015

guest Mod Note: one post went to snippiness. Leave the argumentative stuff and personal digs out of it.�

1/1/2015

guest Why would a post of two words "thank you" go to snipiness ?�

1/1/2015

guest It didn't. Not sure what you're reading.

�

1/1/2015

guest My interpretation was it was acknowledging another poster's comment that was considered inappropriate by the moderator.�

1/1/2015

guest It contained a quote as well: http://www.teslamotorsclub.com/showthread.php/7777-snippiness?p=656452&viewfull=1#post656452�

1/1/2015

guest Thanks for putting that up JRP3...I always saw the snappiness posts being removed and never bothered to look for the removed posts but this time I clicked on your link and read and agree that there are definitely some people on here hired by shorts as trolls to try and deceive us with international lies...then there are also normal honest people shorting the stock who state valid opinions...but sometimes it is hard to know the difference and reading some of the snappiness thread helped me see the line.�

1/1/2015

guest It was immediately clear on reading it that that brilliant Oatmeal piece would boost demand for the model S. And here's proof (& also a good guide to the Tesla's ingenious leasing plans). Tesla Continues To Roll Out Tax Strategies For Consumers - Forbes�

1/1/2015

guest Prediction. One of the buzzwords that we'll be hearing all too often in the future related to Tesla will be Pent Up Demand�

1/1/2015

guest And the milestones continue

Tesla now Californias top automotive employer - Autoblog�

1/1/2015

guest What most analysis seems to miss on the Gigafacotry... and Teslas continued success

Every article I have read on the Gigafactory entirely misses the return stream of packs coming back to the factory.

Seems to me that this is a huge miss when calculating the economics of the factory as well as Teslas ability to hit the price point to make GenIII a huge success.

Additionally, pack/cell reuse and production for home power storage not to mention additional Superchargers is also ignored by most journalists/analysists.

These 2 fundamental aspects of Gigafactory economics are yet one more reason the long term success of TSLA and Tesla continues to firm up and another reason to essentially blow off any conventional guidance. I mean, what am I missing here all this stuff is published material and is a giant portion of lowering the bottom costs here.

Fire away:smile:�

1/1/2015

guest Recycling packs won't have a material impact on the gigafactory until probably 10 years from now since packs will last likely at least 8-10 years. And when gigafactory starts recycling packs it will be in small numbers as not many Model Ss are being sold currently compared to the yearly output of gigafactory.�

1/1/2015

guest I know Model s battery's charge cycle is 3000 until 80% of total capacity. Probably battery packs will last at least 20 years.�

1/1/2015

guest I am convinced the market is under estimating renewable energy storage for "Demand Reduction". Utility demand charging is exorbitant.�

1/1/2015

guest As a recycling enthusiast it isn't lost on me either; it will just take time before serious numbers of old packs end up going back to the factory.

However, Tesla have taken an awesome position with regard to battery recycling, and this shouldn't be passed over. Check out J.B's comments here -

JB Straubel | [email�protected] SLAC 2013 - YouTube

When the world is running fully on electric cars, and all batteries are being recycled, it'll significantly reduce the amount of stuff being dug out of the ground... and waste being put into the ground.�

1/1/2015

guest Hence, the long term thread, but, I guess what I'm stabbing at is the "future" component of the stock price. I mean I know that a significant portion of the momentum price component is a short sighted2-3year time horizon, but a serious long player has to look at the that train on returning packs that will explode exponentially in line with production levels. Additionally, this is the worst case scenario as the 8-10 year time begs the tech advance component as well.

Cheers! �

�

1/1/2015

guest Dave, I agree the returning packs are a huge opportunity, given their roughly 80% capacity remaining. I think the impact of this could well be as soon as three years from now, and a sizable impact potentially. If the Gen III has a base 50 kWh pack, I've looked at a scenario where Tesla could offer a guaranteed $5K replacement pack cost when they start selling Gen III around 2017, AND make money on those replacement packs, and the repurposed turned in packs for grid storage. I could find a post I wrote a month or so ago, but it came to roughly a 15-20% margin on the new and recycled pack assuming roughly $2K to move these packs around and do some refurbishing to old packs to repurpose them into grid storage use.

I already think Gen III will be a watershed success, but if Tesla does something like this on Gen III, it will not only supersize already stellar demand, but kick the door open on one of the remaining misperceptions of EVs... cost of replacing the battery. Knocking out these kinds of misconceptions of course goes to Tesla's mission.�

1/1/2015

guest In fact, given EM propensity for creative financing (pseudo lease)- he may figure out a way to buy from you up front. Contract to bring it in after x cycles, and we'll take y dollars off the car now.�

1/1/2015

guest Why would anyone prepay $5k for a replacement pack when the original is likely to last 400,000 miles or more? 2,000+ cycles at 200 miles per cycle = 400,000+�

1/1/2015

guest People are buying 85 kWh replacement packs from Tesla for $12k that can be picked up no sooner than 8 years from purchase.�

1/1/2015

guest How many are actually buying it? Plus the Model S pack longevity potential is less well established, by the time G3 comes out there should be plenty of real world examples of high mileage cars with little degradation. I certainly won't be paying $5K for a pack I expect to never need.�

1/1/2015

guest JRP3 I'm sure you know far more about batteries than I do, but I believe the general understanding, including estimates from Tesla if I'm remembering correctly, is that after 10 years of average use the packs are expected be around 80% capacity. It's possible Tesla is "sandbagging" the 80% 10 year number if indeed they have said this.

What percent capacity do you think that pack will be at after 400,000 miles?

if most consumers will be happy with the pack after 400,000 miles, Tesla is offering a value far far greater than the public perceives (I believe this is would include nearly all Model S owners and TSLA investors). That would obviously be great news. I think even among Tesla enthusiasts, there's a general sense that their cars will need new packs in roughly 10 years.

I think for a reasonable amount of consumers, they'll at least perceive a desire for a new pack at that point (granted it's possible once EVs have been widely used for years, perception of the need for range may make people willing to hold onto packs longer).�

1/1/2015

guest I'd say worst case would be 70% capacity, but likely much more, 80%+. However I don't think most people will keep the vehicle much beyond 200,000 miles anyway, and I don't expect the 2nd or 3rd owners to care.�

1/1/2015

guest that would be outstanding. JRP3, I'd love to know what you think the typical capacity of ten year old batteries with average usage (125,000 miles) will be.�

1/1/2015

guest Without the time component we already have at least one individual who has 75K on the car with 7% reported capacity loss, actual remaining capacity is probably higher than what is reported by the car. Since capacity loss is greater in the beginning and then tapers off I'd imagine maybe 10-15% loss after 125-150K and 10 years.�

1/1/2015

guest And from some of the side-edge remarks from JB, they expect to make some healthy improvements in the GENIII version in that performance measure. Just my own personal model based on these and other indicators puts a 10% 200k/10year loss figure as reasonable make-target. I don't think they will recycle back into stationary storage though as hat will be a different proportion of the same chemistry makeup, but a recycle into new and fleet taxi-lease makes perfect sense. Going to be fun watching this play out�

1/1/2015

guest We can all guess. I am not a battery expert. So many variables. The 75k, given how long the car is out is excessive mileage. My own experience after 20k miles was a loss of 4 miles on full range after 15 months. I recently completed 1500 mile trip on supercharges taking it down to low levels on charge and charging to full range with supercharges both of which should hurt range but now I have gained back the 4 miles of range lost before the trip. Not scientific but only longer experience will allow us to know answers�

1/1/2015

guest That's what I meant about reported range possibly being less than actual. Your deep discharges and full charges allowed the car to more accurately calibrate capacity.�

1/1/2015

guest At one of the appearances during the latest European tour, I think it was in Oslo, EM mentioned that MS battery (presumably 85kWh pack) was tested at the factory for 500,000 miles. Given published charts indicating 2,000 cycles, assuming that the battery pack starts at 272 rated miles (similar to my pack when new), one can roughly calculate capacity at the end of 2,000 cycles to be approximately 83.8%. I am not a battery specialist, so would appreciate any comments for the following rough calculation:

Initial Capacity = 272 miles

Avg. Capacity = 500,000 / 2,000 = 250 miles

Capacity after 500,000 miles = 250 - (272 - 250) = 228 miles

Percent capacity after 500,000 miles = 228 * 100 / 272 = 83.8%�

1/1/2015

guest That might be a bit optimistic, but maybe not. There are two things to consider, on the one hand the reported cycle testing uses full charge and discharge cycles which are harder on the cells than the partial cycles that the Model S really sees. That would lead one to conclude even less degradation in actual use. On the other hand the time component is much lower on the test cells, which might mean more degradation in the real world. I expect the partial cycling will more than compensate for the time factor.�

1/1/2015

guest My calculation is based on assumption on how the battery would be tested at the factory. I would assume that if TM want to mimic heavy real world use, they would be cycling the battery from 100% to 0 rated miles, i.e. from 100% down to about 10% of capacity. I also think that the test would be defined in quantity of cycles, and 2,000 is reasonable as it coincides with the Panasonic testing chart.

In terms of calendar aging, I am not sure, but would think that if one would want to design "real world" testing protocol, it would make sense to incorporate both usage and calendar aging. So may be when EM referred to testing the battery for 500,000 miles, the testing possibly involved some kind of simulation to account for calendar aging.�

1/1/2015

guest A "full cycle" of the battery in the car is not really a full cycle, since Tesla never fully charges or discharges the cells.

I'm not sure there is any way to simulate chemicals and components interacting over time.

The second graph in this paper is quite interesting because it shows the effects of partial cycling, from 4.05V to 3.6V, 3000 cycles with about only 10% capacity loss, and the loss curve has gone almost flat by the end of the test, suggesting that 4000+ cycles are quite likely.

http://ma.ecsdl.org/content/MA2011-02/17/1282.full.pdf�

1/1/2015

guest Yea, I saw this paper some time ago, and the second graph is very interesting indeed.

What do you think the zero rated miles point in MS is in terms of volts/cell - roughly?�

1/1/2015

guest Probably between 3.3-3.5 resting voltage.�

1/1/2015

guest I haven't seen any discussion here of this WSJ piece on Panasonic's thinking... backed by an interview with JB.

Panasonic Remains Unsure on Tesla Battery Factory Goals - WSJ.com

My takeaway would be:

- Panasonic v likely to go in as big partners for the gigafactory

- ...but there's a different culture there, and there are clearly differences of opinion on the required speed of scale-up

JB's comments are always encouraging, and I think the respect shown to Panasonic by Tesla has to help. Given how important the gigafactory is, they *must* be working on a plan B behind the scenes if Panasonic doesn't come through at the necessary scale. If the companies can pull this off, with the right terms, it will be a giant step forward for Tesla's long-term.�

1/1/2015

guest Elon Musk has been quoted talking about a 40% increase in density compared to the roadster, but JB Straubel has been quoted saying that for most Model S, the battery cost is less than a quarter of the car, so under $25k for an 85kWh battery.

- Capacity ~ range ~ performance ~ charging mph ~ average C rate. Larger capacities make better cars with the main downside being cost and size, with weight being an additional issue.

- With the Gigafactory Tesla is targeting pricing of comfortably less than $200/kWh and at that point 10kWh costs you $2,000 or less.

- Elon Musk has said that for Gen 3, they're still targeting 200 mile real world range with Supercharging capability.

Now put all of that together. Shrinking the battery to 40kWh would:

- give a maximum drop in price of $4,000.

- Make cold-weather climate control loads more significant, significantly shortening winter range.

- Cut maximum performance.

- Lower maximum Supercharger rate. That could lead to 1 1/2 hour range charging times, especially in difficult conditions.

- Raise average C-rate.

To me, the most important element of long-range BEV is Supercharging. With the volumes Tesla is seeking, in order to avoid contention problems, they need to make Supercharging faster (JB Straubel has talked about an aim of 5-minute Supercharging) and cutting battery capacity would be a backwards step. Combined with the other negatives, lowering capacity simply won't deliver the necessary cost:benefit ratio.

I think that Supercharging determines the minimum spec and that's why Elon Musk can comfortably say that the Gen 3 will have 200 miles range, the same as current Model S 60. I think that when Gen 3 is introduced, the new cell technology will allow Tesla to increase the maximum Model S/X battery capacity and they'll drop the 60kWh Model S/X (if they even offer the 60kWh X).

When Elon Musk was asked about the Gen 3 battery costs and said that the car would be 20% smaller, so the battery would be 20% smaller, many assumed that he was talking about the reducing the capacity by 20%. I think that he was talking about needing an increase in cell energy density in order to shrink the battery, which would naturally decrease the number of cells required for any given capacity and, overall, lower the battery manufacturing cost. At Panasonic's earnings release, when the CEO was talking about being careful in investing in the Gigafactory, one of the issues he raised was that they needed to be able to meet Tesla's requirements for the Gen 3 cells. If I recall correctly Elon Musk has said the overall target is a 40% reduction in battery cost, with 15% improvement coming from the improvements to the cell, and the rest from process and scale at the Gigafactory, believing that they can eventually get a more than 30% reduction in costs from the Gigafactory alone.�

1/1/2015

guest On a slightly different topic- but not worth it's own thread- here's an good quick US map of states where Tesla can and cannot sell - no great shakes here- just an interesting visual

In which U.S. states can Tesla sell its electric cars? : TreeHugger�

1/1/2015

guest There are Tesla stores, not Galleries, in Portland Oregon and Indianapolis Indiana.�

1/1/2015

guest Do you know if they can sell-them out of those stores? Or just discuss pricing, point them to website etc.; Maybe those are somewhat hybrid situations- where they aren't allowed to actually conduct the sale and contract but can do most everything else�

1/1/2015

guest The smaller, lighter G3 will achieve similar performance, range, and charge times, with a smaller pack than the S. It's not just about the C rate the pack can charge at, it's about the miles added per C rate, which would be relatively higher with a more efficient vehicle. Say the G3 has a 60kWh pack, it would charge at the same C rate as the 60kWh S, but since it's a more efficient vehicle it would add miles at a faster rate.

I'm expecting the base G3 to have a pack in the 45-50kWh range.�

1/1/2015

guest I was talking about retail cost, which was/is about 40k for each pack. Nobody knows what Tesla's exact cost is/was.

Dropping the 60kWh would be counterproductive. In fact, I think/hope they will reintroduce the 40kWh S when they are no longer supply constrained, or if they ever have a demand problem. This may take years to happen, but I think it will and should.�

1/1/2015

guest Stores = they can sell directly out of them ergo they can discuss price and do test drives.

Galleries = they can't sell directly and can't discuss price.

No Hybrids. No kinda pregnant.�

1/1/2015

guest Analysts slightly bullish on TSLA, not sure what to make of it

Tesla has earned a consensus recommendation of �Hold� from the twenty-three ratings firms that are covering the stock.

The average 1-year target price among brokerages that have issued a report on the stock in the last year is $217.59. Ten equities research analysts have rated the stock with a hold recommendation, six have assigned a buy recommendation and one has given a strong buy recommendation to the company.

This is so different to what I am used with TSLA and analysts and leaves me confused.

The confusing bit is that in the past, when a lot of upside was ahead of us, most of the analysts were saying: Sell, overvalued, etc.

Now we are above 200 and analysts are bullish on Tesla. I am still processing this, not sure what to make of it. I feel this pushing me out of my comfort zone. Time to get out?:crying: I am not ready for that.�

1/1/2015

guest 64% Institutional Ownership.�

1/1/2015

guest guess that chart had some error in it then- thanks for catching those�

1/1/2015

guest As I recall, Nissan started a little before Tesla, with some full grown factories, etc.

Interestingly enough, Nissan paid me and several other Tesla owners to tell them why we bought a Tesla instead of a Leaf. This was when Tesla sales were taking sales away from Leaf. I don't know what the others said, because it was an hour-and-a-half private, taped interview. My answer to them was RANGE.

Before the interview I had to keep a daily log, starting charge, miles for each trip, etc., etc. My log showed that I only drove 30 miles per day, *on average*. There's your data. But on three of the days, I drove *over* 100 miles, one day reaching 180 miles. Would a Leaf work for me? No. Does it work for the average person? Well, Some of them.

What I see is that Leaf owners are really really wanting to drive electric, but being cost constrained, they will put up with inconvenience of having to charge while they are out driving. For visible proof, I see in several forums the excitement of getting new charging points all over every city, county, malls, shops, government buildings, on and on. And Nissan also has 50 amp fast charging. The charging is important to them simply BECAUSE THEY NEED IT.

One of my friends has a Leaf. At times he must make a 100 plus mile trip from one business to another. He must plan to stop midway and charge, and sit in his car for two hours. He claims it is no problem, and he loves his less expensive car.

On the other hand, I had previously owned a RAV4EV with a little over 100 miles range. When I went shopping for a car, I did NOT look for the data on what people said I would need. I already knew that 100 miles was not enough, at least often enough that I did not ever want to sit for four hours recharging so I could get home from the airport.

A 40 kWh Tesla may be what "most" people would use, but at least I, personally, would rather pay extra than have range anxiety, or range inability, or range irritation at having to charge while going some where. With the 85, I don't ever even THINK about range.�

1/1/2015

guest I was wondering how unprecedented this was (as well as wondering along the lines of the rest of your comment.

Fango, I see what you are saying about EV makers potentially prolonging the misconception about needed range. That said, I think Tesla needs to start out as no compromise in reality and perception, and let consumers of their own experience decide what is enough range as the years go by. The other thing to bear in mind, the battery size drives range and performance... a 50 kWh (or even 40 kWh) might do nicely in a light Gen III car, but in the Model S, the performance just wasn't there at least in the eyes of Elon... thus the "hobbled horse" comments.�

1/1/2015

guest Just watched the talk given by JB. I might be the only one to not get it yet, but he seemed pretty clear that the 35 GWh produced was for the 500 000 cars coming from Fremont. The remaining 15 GWh was for energy storage. However, 35 GWh/500 000 gives you 70 KWh per car which I think is pretty reasonable�

1/1/2015

guest [Added the part of a moved message that belongs to the topic of Nissan Leaf sales, discussed above, which the "Update" in this post referred to.]

Tesla sold more battery capacity than Leaf and Volt together (I know it did so at one point, and it is probably still the case), and that is what will drive the developments necessary, for electric cars to become the majority of cars sold: battery price improvements. That is what counts, and it is done by Tesla. Along with demonstrating that electric cars can be compelling ("better") in many ways.

Update: Still true, even globally, for 2013 totals, in battery capacity sold, vs the sum of Leaf and Volt/Ampera.

For the US market, where in 2013 Tesla still had most of its focus, Tesla outdid Leaf + Volt together with a factor of about 1.5x !!!�

1/1/2015

guest http://static.ed.edmunds-media.com/unversioned/img/industry-center/car-shopping-trends/QuarterlyReport_FINAL-5BuyVSLease.pdf

Leasing is on the rise, up to about one quarter of all new car sales. These cars are going to be used for commuting and not for long trips. I hope this means at least a portion of new car buyers are seriously considering how much they actually drive before they engage in these contracts.�

1/1/2015

guest Crikeys - Tesla just missed out on a 112 acre parcel adjacent to their Fremont plant???

Bloomberg is reporting tonight that home-builder Lennar has just signed a deal to purchase Union Pacific's 112-acre parcel next to the Tesla factory. The article states that Lennar's plans including building 3,000 homes and 1mm sq ft of offices and r&d sites on the land.

Purchase price is not divulged, but apparently there were other bidders.

Now, Tesla cannot purchase every vacant parcel in existence, but without knowing anything of that site's market value, it seems on the face of it a shame to have let that one slip by. Maybe 3,000 lucky employees will in the near future have the opportunity of walking to work!

Link here: Lennar Said to Reach California Land Deal for 3,000 Homes - Bloomberg�

1/1/2015

guest Given the high value of houses in the Bay Area, the purchase price was probably way above what Tesla could justify for industrial uses. I have to wonder how many of these new homes are going to be bought by Tesla Motors employees?�

1/1/2015

guest Can we please move this spawned "vehicle miles driven" discussion to its own topic. It's way off topic now and should be continued, but elsewhere. It has been going on so long that I forget the on topic question that spawned it.�

1/1/2015

guest Moderator's Note:I've carved out 100 posts discussing battery sizes and driving habits: Optimal Battery Size and Driving Habits�

1/1/2015

guest Well done, and thank you.�

1/1/2015

guest A high five from me too! Thank you.�

1/1/2015

guest Hey everyone, I was lucky enough to get a factory tour recently by a very knowledgeable employee. There are a couple things that really surprised me and might be of interest to others.

The Tesla Model S actually takes significant more man hours to build than a comparable ICE. I was dead sure before that between all the automation and the lack of drive-train complexity Model S' would be easier to make. They put so much time into quality, and the actual build is purpose driven toward DURABILITY. My guide was well aware of the specifications/design of the car and pointed out how several components were totally over-engineered to never wear out. There are absolutely no wires in contact with other wires and there are close to zero friction points such as this where moving parts might wear over time.

Second, there have been far more Model S tweaks over the last two years than one would think. Certain areas have been re-engineered several times to meet perfection. I was shown some of these and the attention to quality and detail blew my mind. I am quite certain they will never cease upgrading the build of the car.

I also saw the Model X drivetrain and learned about the dual engines and a few other tidbits. I am super excited to see what the final car will look like but it did not sound like additional news of either Gen3 or X will be released anytime soon.�

1/1/2015

guest We had our car serviced yesterday in the new Devon, PA service center.

I was blown away by this new service center. It is massive and they have a lot of room, a huge empty show room with one red S85 and the chasis display. The waiting area is nice and along one of the hallways they have an ordering room with 5+ computers (I didn't count them) for people to sit down and order cars on.

Directly across the street, Nissan, a Volvo dealer one one side of them, VW, on the other side. A short drive down the road, Mercedes, a fee more blocks, BMW.

I walked back to the waiting area and asked the service advisor, "whoa, you guys are getting ready for Gen III aren't you?" She said, "no, we are getting ready for the X." I looked around again and I didn't see the place setup for the X, what I saw was 5 years down the road and hundreds of people swarming the show room and lines at the computer ordering center waiting to place an order for the Gen III.

Tesla is no longer the rinky dink back alley garage type company (Noristown service center) that it was before. It is now in the big leagues getting ready to pierce right into the heart of the automotive market.

I would be shocked if they are not positioning themselves like this elsewhere.�

1/1/2015

guest I will second this sentiment. I have also been to the Devon location. I suspect it will be one of several east coast hubs for major ordering/delivering and servicing of not only the S and X but certainly has the room in the waiting (showroom), service, and parking areas to deliver hundreds/thousands of cars (E).

For those living in other areas: Devon, PA. is part of the 'main line' in the greater Philadelphia area. Lots of wealth (yea, not trying to stereotype but not everyone can afford an S or X) and convenient to eastern PA, DE, and southern/mid New Jersey.�

1/1/2015

guest An interesting article about Audi's EV plans: http://www.reuters.com/article/2014/06/19/us-audi-electric-cars-idUSKBN0EU1RB20140619

They plan to introduce BEV based on R8 in 2015, with claimed range of 280 miles. The R8 is a low volume sports supercar, so on a face of it Audi is at least 8 years late to the BEV space, if one draws comparison with Tesla Roadster. At least they borrowed strategy from the Tesla book - starting with high price low volume BEV...�

1/1/2015

guest An Audi R8 EV is going to be even more expensive than a 2008 Roadster. You're right, Audi is way behind in EV development. They should have introduced a serious competitor to the Model S last year. What is taking them so long?�

1/1/2015

guest They cancelled their e-Tron when the S came. They didn't want to be laughed at. This is seriously what happened.

Edit: Yup, it's even in the article above:

"Audi's electric-car moves highlight a change of tack at VW. In 2012 Audi shelved the R8 e-tron at request of its parent as efforts to expand the model's driving range had stalled at only 215 km.

Audi, which has since swapped R&D chiefs, has overcome the range limits by increasing the efficiency of the electric drivetrain and curbing on-board power consumption, development chief Ulrich Hackenberg has said."�

1/1/2015

guest Good.

Still smoke today, but I hope they deliver what the article says, in the timeline discussed. Then we'll have a real competitor to a Roadster, and we'll have another company into the innovation pipeline that will lead to a Model S competitor, and more.�

1/1/2015

guest Audi is the world leader in electric vehicle press releases. Call me when they actually make one. Until then they deserve no attention. This is all just smoke to make it seem like they're working on something and to get people to delay their ev buying decisions.�

1/1/2015

guest �

1/1/2015

guest I dunno - this is really tough field - too many strong entrants for the title...�

1/1/2015

guest Nissan Prices LEAF Battery Replacement at $5,499, New Packs More Heat Durable

I don't know where the price per kWh thread is, but just noticed this plan by Nissan to sell replacement Leaf packs for $5,500, after credit for turning in your old pack (which they value at $1,000). Balances out to $270/kWh.

I hope we end up seeing a similar deal, at a similar (or lower?) price for Roadster replacement packs, and an update to new technology so the pack can be made 200-300lbs lighter. I'd love to get a 300lb lighter car for ~$10k (or less? like if my battery still has a super high CAC? pretty please?).�

1/1/2015

guest Since Nissan requires the old pack to traded in for the new pack, the actual dollar amounts are misleading. The trade in is valued at $5,500, but do you really believe the old pack is worth $1k? In other words, they could have said the new pack is $10k and the trade-in amount is $4.5k and the difference is the same.

We would know the real value of the pack if Nissan was willing to sell the new pack for $x without a trade-in.

For reference, David Nolan's trade up from a 60kWh to a 85kWh pack was about $300/kWh in difference between the packs in new pricing. His ended up higher because of the 20% restocking fee and the labor.�

1/1/2015

guest The Tesla factory in Fremont will not be producing any cars for two weeks. During this time they will install the second production line. This was mentioned on May 7th at the Conference Call. We haven't heard anything about it since, have we?�

1/1/2015

guest I have tour 1st week august. Suspect kinks will be out by then. Anxious to go�

1/1/2015

guest Anxious to learn what you will find out in August. Keep US informed. Thanks�

1/1/2015

guest Benz...I remember you collected some good numbers for European deliveries last Q. Will you do again? I am NOT fluent in the European languages but would be willing to help if you point me in the right direction.

Thanks Al�

1/1/2015

guest Hi Al,

After the Q1 2014 Conference Call on May 7th I realised that something was missing, and that we should be doing it more properly. After having collected all the delivery figures from all the countries, we should be able to put them in some kind of a spreadsheet. When the delivery figures of several quarters/years will have been added to this spreadsheet, then it will be possible to make some nice graphs and more of those kind of things. This spreadsheet then will become a source on its own. That's the idea. But I haven't really discussed this idea with anybody yet. I think it's important that it should certainly become like one of those blue sticky threads which always stay on top of the page within a forum page.

What do you think about this idea?�

1/1/2015

guest Good idea. I would think, Robert, the moderator of the investor area would support such an idea.�

1/1/2015

guest Would love to but already notified of standard nondisclosure pact. As volume of cars pickup would love for them to start disclosure of monthly sales numbers (not deliveries but order numbers). That might take some volatility out of the stock. I had previously heard Elon mention that he wished there was less of that.�

1/1/2015

guest We could get a thread with a Wiki summary that anyone could edit; that summary post could have a table with the relevant data. If that would be useful, I'll have an admin set that up.�

1/1/2015

guest Thanks for your assistance and help, Robert.

But I don't think that just everybody should be able to edit the data in the table/spreadsheet/wiki. We, the members, should only be allowed to collect Tesla Model S/X delivery data (from several sources) and post it in this particular thread, and we must mention the source where we will have collected the data from. After that the Admin or someone else must enter this delivery data in the table/spreadsheet/wiki. Just like how it works with that "Tesla Model X Tally" -thread. We should do it similarly, I think.

Please correct me if I have misunderstood what you have meant to say.

Thanks�

1/1/2015

guest I would be guilty not to post this article:

Apple? Google? Tesla? Which Will Be The First To Reach A $1 Trillion Market Cap?�

1/1/2015

guest Yes please.�

1/1/2015

guest Here are some fun calculations. Let's assume Apple current market cap = 500B. Apple TTM sales = 178B. If Tesla had to match the P/S ratio of apple, how many cars at an ASP of 50k does it need to sell to achieve a 1T market cap? The answer = 7.2M. Now lets add in grid storage and if we assume that 50% of Tesla revenues at this future point of 1T valuation come from storage, then the number falls to 3.6M. When will Tesla sell 3.6M cars? My guess is 2030. So here you go Tesla 1T by 2030.�

1/1/2015

guest Fun but unrealistic, since Apple's margins are way higher than Tesla's margins ever will be.�

1/1/2015

guest Tesla will in all likelihood never reach Apple's 39% margins but IMO is way more susceptible to being replaced as the most prestigious brand in its category.

Therefore putting unrelenting pressure on its margins.�

1/1/2015

guest YeahIt can have a higher P/E though if it is still growing faster than Apple currently is.

�

1/1/2015

guest Wouldn't it be better to conject that Tesla's market cap increases to what Toyota's is today?

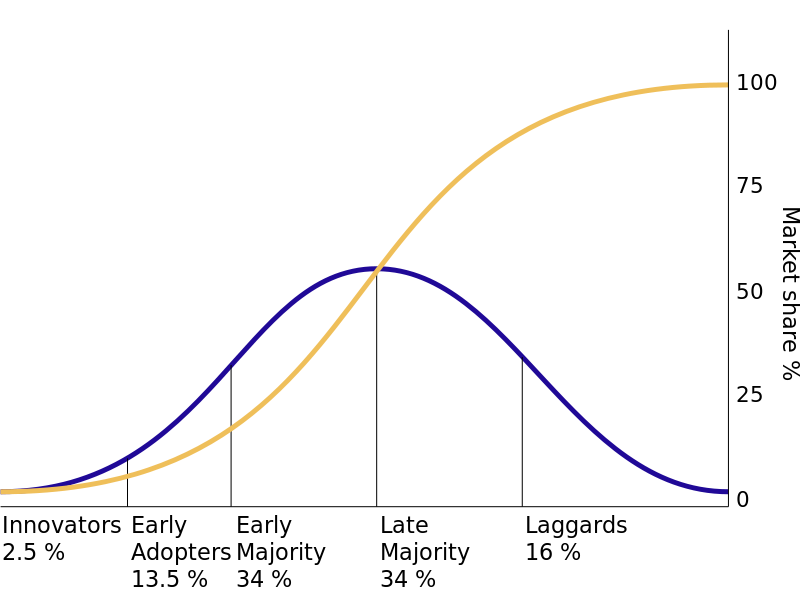

Tesla would be the world's largest electric car company by that point, producing more electric cars than anyone else, and also with fingers in the home battery storage markets, and charging infrastructure + battery recycling/production industries. This would probably be 15yrs from now in 2029, half-way through that adoption bell-curve diagram we have seen many times.

Today, Toyota is $189billion. TSLA stock would be $1,524 at that size, assuming no stock splits etc..�

1/1/2015

guest Sure it'll have a higher P/E right now because it's growing faster. But to compare P/S ratio of Apple and infer that it's possible for Tesla to reach that someday isn't realistic because margins are different in tech vs auto.

- - - Updated - - -

Tesla has higher margins than Toyota (and likely will continue to do so in the future). So even if Tesla sells the same # cars as Toyota (ie., revenue), their profit will be greater and that will lead to a higher stock price than what the market gives Toyota right now.�

1/1/2015

guest Interesting debate/discussion. If you factor in the battery storage market potential I wonder if it could reach those margins? Probably not, but I wonder what margins would be on that segment of TM business.�

1/1/2015

guest Apple reaching close to 40% gross margin on hardware is unique. The big reason for this is because phones (especially in the U.S.) are on 2 year contracts, cost spread out over time, and only a few major carriers to choose from. So Apple is able to charge $600+ for a phone that costs them like $200-$250(?) to make. They make huge margins on the iPhone and that offsets the lower margin they make on all their other products (i.e., Macs, iPads, iPod Touches, etc). I'd imagine if Apple didn't have the iPhone that their margins would be under 30%, and maybe even under 25% (though I haven't researched this).

Regarding battery storage market, I don't see it as a particularly high margin business because the bulk of the cost is going to be the batteries, and then it's the value on top of that that the software, servicing, etc brings. I think Tesla could make some money by providing servicing contracts where Tesla monitors and maintains the battery storage units and makes sure they are always running in optimal conditions providing the best energy savings for the customer. This is where the bulk of the profit will likely come from IMO. But overall, I would imagine margins might be in the same ball park as their cars over time.�

1/1/2015

guest Hmm, so lets take net margins. Apple net margin = 21%. IF Tesla can have net margins of 10.5%? Then with the P/E of Apple, they need to sell 7.2M cars at an ASP of 50k + equivalent in storage to get to 1T. I'd guess 2035 for that. But that requires that a new gigafactory shows up every year starting 2020.�

1/1/2015

guest I think your numbers are too optimistic:

1. If/when Tesla sells 7.2M cars, it will be because they got into economy cars (ie., $20-30k) and the economy cars will make up the majority of their sales. Therefore ASP will likely be $35k (maybe $40k if they're lucky). Of course this all depends on inflation as well (so I'm talking more in today's dollars).

2. Energy storage - so you're estimating they can sell $360 billion (!!!) of energy storage per year? Hmmm. I don't see where you're getting those numbers. Have they even sold $10M of energy storage yet?

3. P/E for the auto industry is generally much lower than tech (ie., Apple). Look at the P/E of BMW, Mercedes, Toyota, etc... they are all currently growing at a decent rate but have P/E of around 10.�

1/1/2015

guest I know they are too optimisticJust having fun with the trillion dollar headline from a page or two back. GMs current average transaction price is ~35,000. So Tesla can do 50k average and still sell 7.2M cars at some point. Especially in something like your Tesla 3.0 scenario. Assuming other are makers are not yet heavily into electrics in a decade, the TCO of Tesla cars would still make them attractive compared to a 35k hybrid car right?

I don't even know how to begin to anticipate the storage market. At what point will storage be the mechanism for utilities to shave off peaks? When will businesses and residential customers use it to shave off peak pricing? What would be the market for that? What will be solar/wind penetration 20 years from now? Will it be standard to have a battery with the system by then? What would be the size of a standard battery? How many kWh of batteries would sell per kW of solar?

But we can guess how much Tesla will have for storage. Assume that 35GWh/factory is for cars and 15 is for storage. Then 15 gigafactories * 15GWh = 225GWh at $200/kWh = $45billion. Can the margins on this be 50%?�

1/1/2015

guest Let's do a little back of the envelope on the size of the stationary energy storage market. In 2008, the globe consumed 143,851 TWh of electricity. Suppose Tesla could address 1% of that with stationary storage. That works out to nearly 3,941 GWh of daily storage. Let's suppose that Tesla systems lose out 10% capacity every year with 365 daily cycles. And suppose that the global energy market grows 3% per year. So steady state about the annual demand for new systems is about 13% of existing capacity. In 2025, then, we're looking at 5,455 GWh of existing installed capacity and annual demand of 709 GWh for new systems. At $200/kWh, that's $142B in annual sales for 1% of the global electricity market.

The above is just a steady state analysis. It doesn't really describe how we get there. The near-term dynamics are complex. There will be many different applications and critical price points at which storage becomes economical. Consider just one pathway, rooftop solar. Because of intermittency, solar without storage can only supply a fraction of the daily need for a home or business. Let's say no more than 10 kWh/day of the average 30 kWh/day per resident. This limits how much solar a resident might install. With 10 to 20 kWh in storage, one can install maybe two or three times as much solar. Basically, once the cost of storage comes down low enough to beat grid prices, it will be economical to buy storage coupled with solar. Thus, the growth rate of storage will be coupled with solar. So if solar continues to double every 2 to 3 years, then so will demand for storage coupled with solar. Moreover, this coupling could also accelerate growth in solar as solar installed per roof is doubled or tripled. Once we hit the tipping point in price, i suspect the only thing holding back storage will be supply constraints.

I don't see how Tesla could possibly exhaust the opportunity in this market. Opening one new Gigafactory every year for 15 years won't be nearly enough.�

1/1/2015

guest Tesla's cells should not drop 10% of capacity after only 365 cycles, more like 1000+ cycles.�

1/1/2015

guest Also a cycle is a full charge to full discharge, not just partial cycle of the pack.

Btw one way we could get to a trillion is with mergers. What if scty buys up solar installers and producers, and merges with tsla? Add spacex for good measure, maybe Toyota or Mercedes or something too. There's your trillion. We would be diluted but were just talking about mkt cap here.�

1/1/2015

guest Additionally, SolarCity is building a massive factory for panels. It seems to me this is the equivalent of the Fremont plant requiring X batteries for X car production. SolarCity builds X panels for a complete home/commercial storage battery consumer of X Tesla cells.�

1/1/2015

guest Regarding margins, 3 things to keep in mind:

1) Margins will undoubtedly increase with economies of scale. TSLA will have significantly higher margins building 500k cars per year than currently. Perhaps not AAPL margins, but certainly much, much higher than Toyota or Ford.

2) Battery technology in 10-15 years will greatly improve, reducing TSLA's largest expense, enhancing margins.

3) Once EVs go mainstream (I believe that they will, especially when #2 happens), competition will be stiffer. Although that will cut into margins somewhat, AAPL (since they are the market leader) is able to maintain higher margins than its competitors, and I believe the same will be the case for TSLA.�

Không có nhận xét nào:

Đăng nhận xét