Jan 24, 2013

Ingineer Here's some Tesla battery "secret sauce" for your enjoyment: (Don't even bother asking me how I was able to take these!)

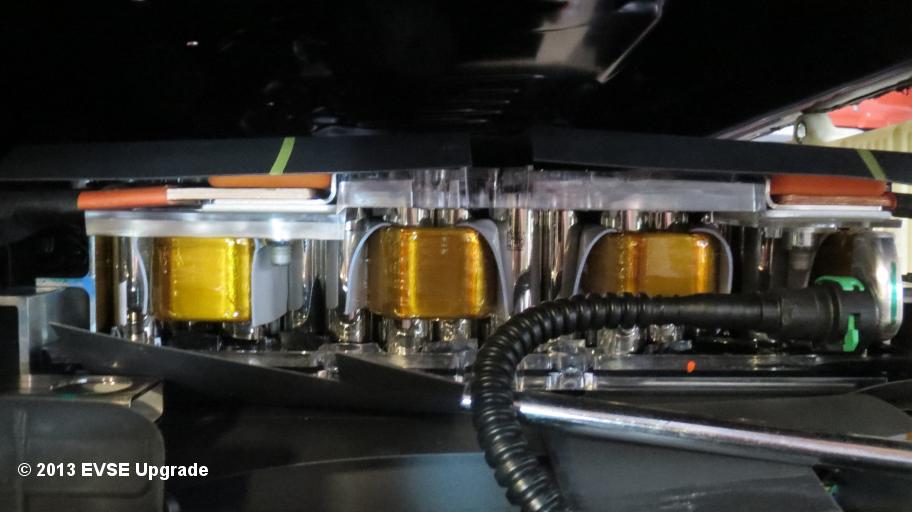

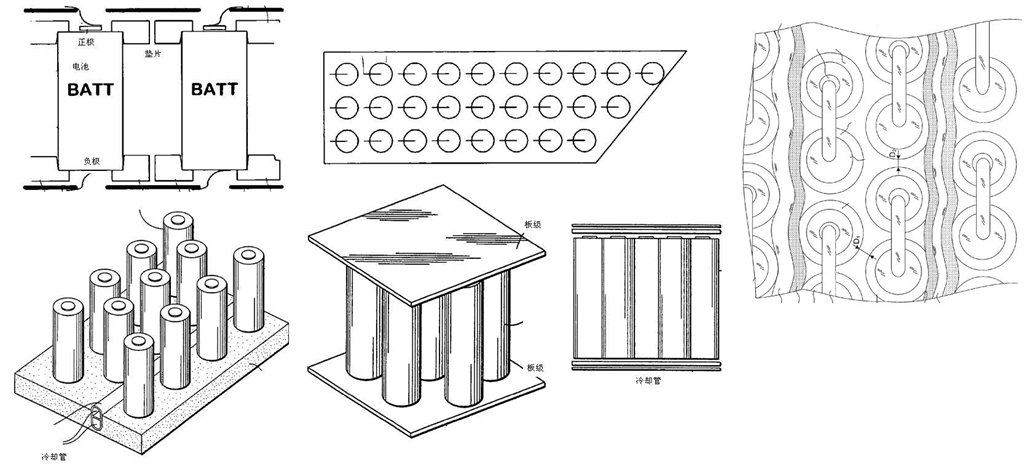

Here you can see the bare 18650 laptop cells. They are interwoven with an aluminum channel (golden color) that carries coolant to each cell. Looks to me like a good 25% of each cell is in contact with this. (via way of a thermal pad and kapton electrical insulator)

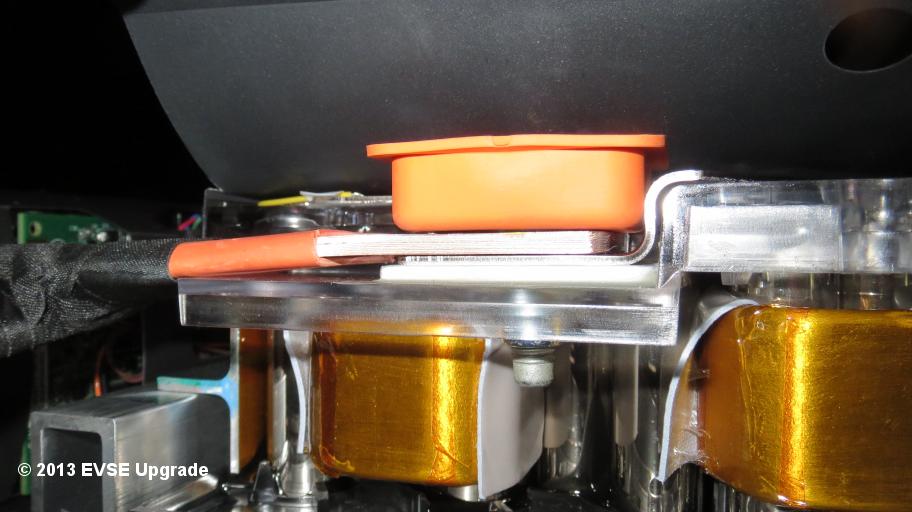

Very large buss bar interconnecting the modules made of thin laminated strips of copper, that way it's still flexible.

This is the top of a module, each cell is connected to it's buss via a tiny single wire, which helps distribute current and acts like a fuse in the event of a cell fault.

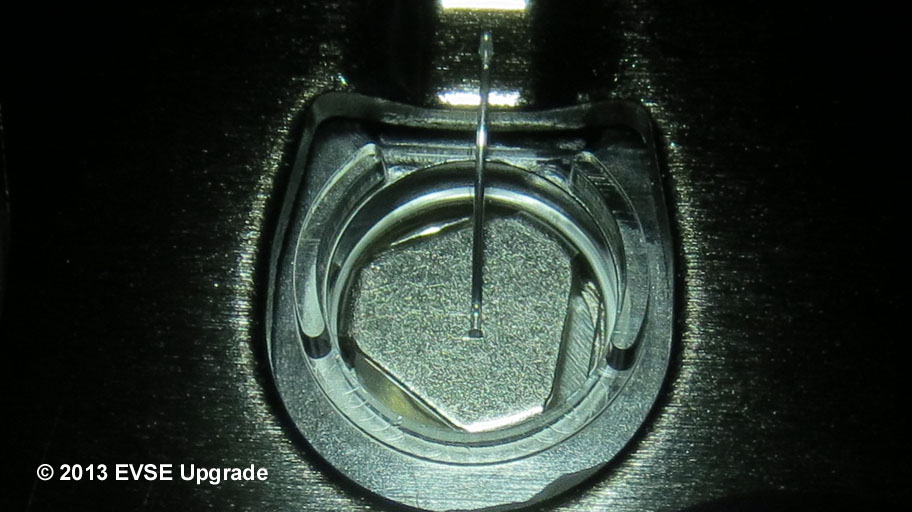

Close up of the cell connection detail.

-Phil�

Jan 24, 2013

efusco Wow Phil, very cool, very interesting. I do want to ask how/where you got these, but don't expect an answer. Very interesting stuff.�

Jan 24, 2013

Kipernicus Another question to ask, related to "how did you get them" is "Is Tesla ok with you posting them?"

As a stockholder and general fan I'm against any unsanctioned leaks of intellectual property.�

Jan 24, 2013

Ingineer I can assure you this is not a "leak". We aren't living in China where we can expect to be censored! It's perfectly legal in the US to buy a product, take it apart, and post pictures all over the internet. Besides, any competitor that wants to buy a Tesla and tear it apart, can and probably will. It's not going to hurt Tesla or the stock price.

-Phil�

Jan 24, 2013

jomo25 Well, I'd imagine Tesla would prefer them not posted. But that never stops the iFixit people dissecting every new iDevice released.�

Jan 24, 2013

AnOutsider Lets enjoy the pics and not get tesla's panties n a bunch FOR them

Pretty cool, though it seems the connectors to the batteries are somewhat flimsy?�

Jan 24, 2013

ElSupreme Wow really cool. Who let you open up their battery pack?�

Jan 24, 2013

Doug_G Tesla sure won't be happy to see that posted online. Unfortunately, if you own the car and don't care about the warranty, there's not much they can do to stop you taking your car apart.�

Jan 24, 2013

PureAmps Cool pictures. I hope you were able to put it back together again, and not be left with an expensive "brick" of a car.

As others have noted, I'm sure Tesla isn't happy about such pictures, but there really isn't much they can do about it. Once they have sold the car to you, it represents a "public disclosure" of any trade secrets. Presumably any significant intellectual property has been patented or in the process of being patented.

I think I read somewhere that Elon was using patents to protect all IP at Tesla, but primarily using trade secrets to protect all IP at SpaceX as there was minimal risk of "public disclosure" at SpaceX, but the Chinese could easily read any SpaceX patent filings.�

Jan 24, 2013

efusco Tesla HAD to know it was only a matter of time before not only battery pack photos, but diagrams, would be online. There'll also be breakdowns of the motor, inverter, and many other things. Once you own something it's yours to do with as you please. It's the way of business and Tesla won't be upset in the least, nor will they be surprised.�

Jan 24, 2013

tezco Building that interlacing cooling channel looks like quite a challenge. Guess we'd better follow the coolant replacement guidelines carefully.

Can you replace any of the modules separately, or is a complete battery change required?�

Jan 24, 2013

yobigd20 Hmmm the MVPA agreement specifically stated you agree not to reverse engineer the vehicle. I would consider this a breach of contract and thus liable for damages.�

Jan 24, 2013

Kipernicus While I don't deny any of that, when you start a post with "Don't even bother asking me how I was able to take these!" it just raises a bit of a red flag, no?�

Jan 24, 2013

ElSupreme I read that as "I had to use a saw and cut open the pack." not "I stole these pics from Tesla."�

Jan 24, 2013

AnOutsider This is the only car forum I've ever been on where the concern is more for the feelings of the manufacturer than the knowledge of how our cars work and perform. I guess it's the nature when there's so many investors and "non techies"/car buffs in the mix, but seriously, we've been given some cool insight, and most of the posts are debating whether or not the poster will get in trouble for sharing.

If he does, he does. I'm the meantime. Lets dissect!�

Jan 24, 2013

Hank42 Coolant replacement Guidelines?

So you mean to tell me there are published coolant replacement guidelines? Did I miss something somewhere?�

Jan 24, 2013

tezco I'm sure there are guidelines, but thus far no service manual is available as far as I know. Hope that changes.�

Jan 24, 2013

PureAmps The key part of that clause in the MPVA is at the end: "only to the extent permitted by applicable law." Their lawyers can put that clause in the MVPA, but they cannot change existing law. In that regard, it is quite clear that you can reverse engineer all you want when it comes to physical things. Tons of case law on this including US Supreme Court cases. The grey area is software, especially with regards to the Digital Millennium Copyright Act (DMCA).

BTW, I'm not a lawyer, I only play one on the Internet. �

�

Jan 24, 2013

markwj Roadster or Model S?�

Jan 24, 2013

tezco I suppose it depends on what the legal definition of reverse engineering is. It might be that there is a need to prove intent to use or sell the knowledge, and/or some threshold of damage which would need to be exceeded. Perhaps some the legal eagles in our midst can enlighten us?

I did briefly consider that clause when I decided to monitor and publish my energy usage (at the wall), but I decided that it would probably pretty difficult to construe that as reverse engineering, especially since none of the monitoring eqipment is in the vehicle, or on the charging cable.�

Jan 24, 2013

shokunin Anything that is critical IP to Tesla is likely to be in the process of being patented, if not already. I'm sure other car manufacturers will buy a model and tear it apart to see what makes it tick.�

Jan 24, 2013

gg_got_a_tesla Amen! Happy to gawk at it and learn more as long as it's not my battery pack. Thanks, Phil.�

Jan 25, 2013

TEG Telsa might have you do an MVPA to get a Model S, but does Toyota do that when you buy a RAV4EV ?

For what it is, Phil's pictures portray a work of art from what I can see.

Tesla creates well engineered objects of nerd beauty.�

Jan 25, 2013

HVM Looking both R and S photos, I think Ingineer's pics are from rav4 pack.

(Even if this is Model S part of the forum. ANDDDdd TEG said that already...)�

Jan 25, 2013

ElSupreme Hells yes. This!

Well not my car until the warranty is up. I am all for tinkering and messing around but I normally wait for the warranty to expire before I do anything serious. Like say opening up a battery pack.�

Jan 25, 2013

mknox +1 I was thinking the same thing myself. I don't recall ever seeing debate like this when the new iPhone is dissected and broken down into costed components (and we all know how Apple can be!).�

Jan 25, 2013

lolachampcar Phil,

You are the man and PLEASE post more pics (or point me to your site so I can see more). I'd love to understand the engineering and have no desire to ever build a pack myself.

As for changing cooling fluids and providing manuals, please do not get me back up on that milk create. Large OEMs are obliged to provide service manuals for third party service providers and documentation to their diagnostic interface so that people like AutoLogics can build test tools (that even support module re-programming). Even little ole non-cooperative Ferrari has to do it although they throw up as many obstacles along the way as they possibly can.�

Jan 25, 2013

RDoc Excellent! Presumably this is an 85 kwh battery.

The next issue is going to be the control protocols for the battery. If third parties are going to be able to reload these with new and/or higher power cells they're going to have to reverse engineer the communication link between the battery and the car. Hopefully Tesla didn't encrypt it.�

Jan 25, 2013

timdorr Honestly, given that Tesla is such a thought leader in this space, I doubt I'm ever going to trust any sort of third-party battery pack for a Model S. They would have to be some top-notch MIT grads for me to even give them the time of day.�

Jan 25, 2013

mpottinger You can be quite confident that every major car manufacturer has, or soon will, tear these things apart to see how they work. Next will be the hot rod and performance folks. If Tesla sells enough of them, you can also expect that there will be an aftermarket develop for replacement and upgrade parts. Bought a 60kw car and after 5 years want it to be an 100kw car? If Tesla won't sell you the upgrade, you can bet someone else will. Saleen, Rousch, NAPA, and all of the boy-racer speed shops have been doing it for years with varying degrees of factory support. The aftermarket for performance and upgrade parts is worth billions of dollars and employs 1000s of people. All of those businesses and people are not going away because we all decide to drive EVs. Also, there are laws that protect the industry's ability to sell these aftermarket parts. Most important, it's human nature to take whatever we have and make it faster. It will be fascinating to see what develops in the future.�

Jan 25, 2013

HVM Nope, it's 41.8 kWh battery pack from second generation Toyota RAV4EV. (TEG also say so, it's must be)�

Jan 25, 2013

Beckler The thing is, Tesla could already make a crazy supercar version of model s. Assuming peak current draw is already near the max for these cells, just wire the pack differently (in parallel) to double the current output, beef up the electronics (and whatever else) and put in a 900 hp motor. In fact they might as well offer this as an option since a 40kW battery already is. It'd probably need to be 2-motor AWD though, with that much torque...�

Jan 25, 2013

drees Homer Simpson - In This House We Obey The Laws of Thermodynamics - YouTube

No matter how you wire up the pack, each cell is going to see the same current for a given power draw.

Way you can make a crazy supercar version battery pack:

1. Allow for higher power draw from the pack and accept the drawbacks associated with that (in fact Tesla already does this with the 40 and 60 kWh packs and compensates by reducing the warranty terms for those packs).

2. Add more cells to the pack so each cell sees less current. Of course, this adds weight which reduces performance gain.

3. Replace current high-energy cells with high-power cells which can handle more power without issue. Drawback is that these cells can typically hold less energy so range will be reduced.

Back to the great pics Phil posted:

Interesting that they use such a small wire to carry the current from each cell. It looks to be no more than 26ga wire or similar? With over 7000 cells in the pack and a peak power draw of 310 kW, each cell is responsible for about 45W under peak load. With a lithium-cobalt cell having a nominal voltage around 3.7V, that's about 12A per cell over that tiny wire. Sure the wire is short, but I still have to wonder how much power is lost in each one under heavy load... I'm sure one of you EE guys will be able to calculate this quickly. �

�

Jan 25, 2013

Beckler Well, no. You can also think of it this way. 2 cells in parallel give you twice the capacity because the current is now half thru each--voltage & power staying the same. Perhaps you're thinking of capacity, which doesn't change no matter how you wire the cells (obviously)(Though higher currents will effectively lower capacity because of higher power losses thru heat).

�

Jan 25, 2013

ElSupreme Well moving batteries from series to parallel will double you current (I), it will also half your voltage(V), and give you no power (P) gains. And P=IV shows this. half V and Double I and you get the same P.�

Jan 25, 2013

Beckler Well it comes down to how the battery is wired. We know it's not purely a series or parallel arrangement of cells because I don't know what the final voltage of the battery pack is, but I'm pretty sure it's neither ~4V nor ~28,000V (assuming 7000 cells). So it's a mixture of both arrangements. To get more current handling, you just move to more parallel groups. Or think of it this way: assuming the 40kw packs are half the size, just wire two of those side by side in parallel. Well you can do that internally with an 85kw pack.�

Jan 25, 2013

Oyvind.H Correct. You cannot "wire differently" to be able to get higher discharge rate without reducing voltage.

Switch cells to ones who allow higher discharge rate is your answer, with different cell chemistry.�

Jan 25, 2013

TEG Since Tesla seems able to make very powerful motors/inverter combinations, and the battery pack output power is apparently the limiting factor, there is still hope someday that they could put an "ultracap front end" to provide bursts of high power for quick passing and 0-60 "hole shots", and then have the lithium-cells recharge the ultracap buffer at a more cell friendly rate.

It would be nice if the 40kWh Model S had the same 0-60 performance as the 85kWh versions...�

Jan 25, 2013

Alpha You could also use the ultracap for regen braking- thus prolonging the battery life, and giving better regen performance on really cold days.

- - - Updated - - -

Actually how do we know for sure there isn't some kind of ultra capacitor inside there already? I've heard Elon Musk often talk about how ultra capacitors may one day be good enough to replace the battery entirely. So I think we can safely assume that Tesla has carefully researched and considered all the angles for use of that technology in the current production Model S... (that doesn't of course mean there is one in there-- they probably would talk about it more if it was... on the other hand, they keep so much stuff secret...)�

Jan 25, 2013

Todd Burch The major difference being that Tesla's existence is fragile at this point, whereas Apple is worth hundreds of billions of dollars.�

Jan 25, 2013

AnOutsider That changes the curiosity of the owners of the product, how?�

Jan 26, 2013

Todd Burch No. That changes the sensitivity of the stockholders and enthusiasts to exposure of IP.

I was just pointing out why some have concerns about this being posted, whereas the same concern is not shown for Apple.

Personally, I don't mind since others are going to tear it apart anyway...just pointing out the difference.�

Jan 26, 2013

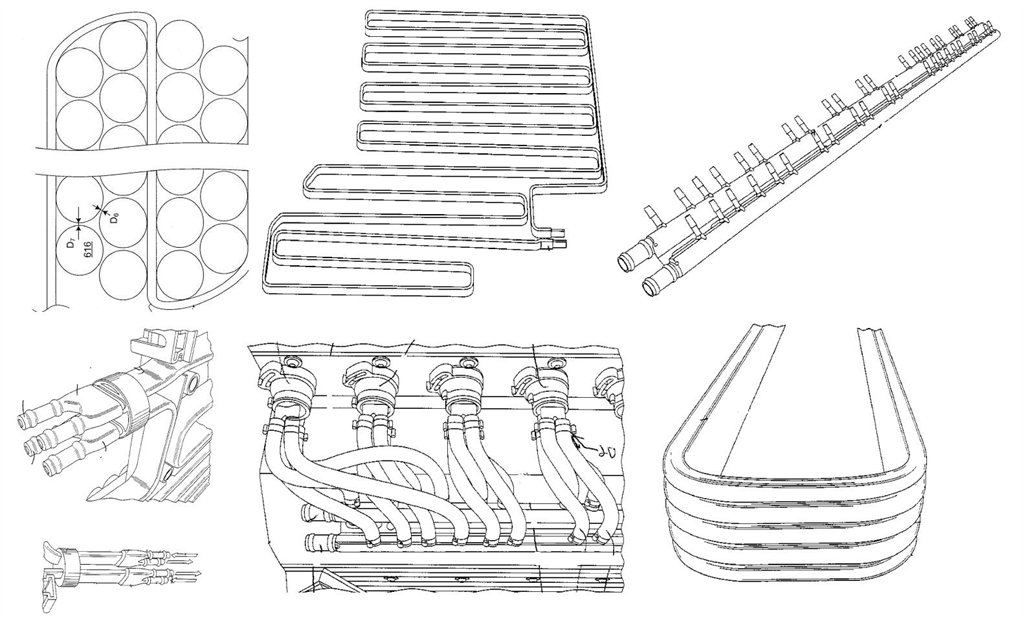

doug Nice photos. Looks pretty much like the scheme used in the Roadster battery pack. There were some diagrams a couple years back posted here from (dun dun DUUUUUN) China.

Roadster battery (ESS)

�

�

Jan 26, 2013

ToddRLockwood Don't forget that this small wire is intended to act as a fuse, to protect the cell from overload.�

Jan 26, 2013

dtich this. was going to point that out too. it's probably sized exactly for that purpose.

i like that in the pix and the parts of the charge cable you can see the trickle down tech from the space program in that they use silver plated connectors and the cable routing, etc. very reminiscent of many pix i've seen of rovers and satellites and iss components.driving a spaceship.

�

Jan 26, 2013

adric22 I'm curious, and I cannot tell from the photos, are these battery cells soldered in? Or are the connections simply being held together by force? I'm just wondering because I'm curious how hard/easy it would be to refurbish a Tesla battery pack in the future when it dies and is out of warranty. Being that it uses standard 18650 cells, I would think of all of the EVs on the road right now, Tesla packs would be the easiest to refurbish yourself. If no soldering is required, that makes it even that much easier. The cells in our Leaf and Volt are completely proprietary so we'll depend on Nissan and GM to provide replacement packs.�

Jan 26, 2013

drees Oh, I realize that, I just wonder what compromises were made to accommodate that design choice.�

Jan 26, 2013

vcor Looks to me as if the battery wires are welded, which makes sense if you want the most reliable connections. If you open up almost any rechargable tool, you'll find the battery connections welded to the battery. As for the 18650, that really just a style/size and doesn't indicate the battery chemistry (there are a number of 18650 cells with different internal technical designs. Tesla has stated they use an Automotive grade version, so they may have something special or semi-custom.�

Jan 26, 2013

qwk The connections look to be soldered to a metal piece that touches the battery. I haven't seen an 18650 cell that has a triangular raised top.�

Jan 26, 2013

Cool-Model S I am curious why Tesla did not go with Li-Fe batteries that are much safer, highly stable, retains high capacity (>80%) after 3,000 cycles of charge/discharge and would be well ahead of competition (probably cost!). I don't know safety aspects of Li-Ion from crash testing and fire perspective. There has been reports of Li-Ion battery issues sporadically world wide (latest being Dreamliner). Any thoughts?

Thanks for the pics? I see no problems in sharing as this is not a violation of IP unless it was patented and copied. I am sure competitors have done it already.�

Jan 26, 2013

jkirkebo Because LiFePO4 energy density suck. You'd get a 35kWh battery instead of a 85kWh battery for the same amount of cells.

While the Panasonic cells are 3100mAh, 3,7V (~11,5Wh), a typical 18650 LiFePO4 cell is 1500mAh, 3,2V (4,8Wh).�

Jan 27, 2013

jerry33 There are many different chemistries in batteries that come under the Li-Ion umbrella. The chemistry used in the Model S is far different than the chemistry used in the Dreamliner. PenFed sent an email on this issue. (Post #14). I'd be more concerned with my ICE car catching fire.�

Jan 27, 2013

JRP3 What I'm struck by is the empty space and space used for cooling. It looks as if it cuts the energy density of the cells by quite a bit. A prismatic cell that didn't need as much cooling could potentially raise pack density even if the cell density was lower. A123 EXT cells maybe? Certainly room for improvement at some point.�

Jan 27, 2013

stopcrazypp Besides from the sucky energy density, Tesla makes up for the cycle life deficiencies of the cobalt based cells (LiCoO2 in Roadster, NCA in Model S) by using lots of them. Example: 73 miles*3000 cycles = 219000 miles of use, 265miles*500 cycles = 132500 miles of use (the numbers might be better for the larger pack than indicated, because the larger size also means the discharge rate is lower, which improves cycle life).

They make up for safety and thermal performance by having active cooling (which the Leaf notably skimped on) and multiple safety features. Electrically, they have a built-in thermal fuse, a built-in pressure fuse and two separate short circuit current fuses (one each for cathode and anode) for each cell. They also have a fuses at the module level. Mechanically, the cells have a metal casing and are small (so there is less damage per cell compared to the 5-10x larger prismatic cells other packs use, plus smaller cells ensure a much larger surface area for heat dissipation). Each module and the overall pack casing is also metal (as opposed to plastic, like in the Volt for example), which helps containment of the fire if one occurs (the Boeing pack was designed like this too, the fire was completely contained inside the box).

http://large.stanford.edu/publications/coal/references/docs/tesla.pdf

- - - Updated - - -

NCR18650A is 245Wh/kg and 530Wh/L (prismatic).

https://industrial.panasonic.com/www-data/pdf2/ACI4000/ACI4000CE25.pdf

18650 has 0.02106 liter of prismatic volume (using 18mm*18mm*65mm rather than the cylindrical equivalent). NCR18650A is 11.16Wh and 45.5g.

A123 AMP20M1HD-A pouch cell is 131Wh/kg and 247Wh/L.

http://ecomodder.com/imgs/a123_systems_amp20_data_sheet.pdf

So Tesla can afford to use twice the space of the cells for cooling and still have the same module/pack volume density as the A123 prismatic cells. I think the main issue is the weight though (NCR18650A is twice as energy dense in weight also).

Plus, it's not like the A123 cells don't need cooling (their cycle life is drastically reduced at higher temperatures ~5-6x shorter at 65 degrees C compared to 25 degrees C). At minimum they need aluminum fins for liquid or air cooling (as shown in the modules that A123 sells). And they definitely can't be packed extremely tight in the first place (pouch cells need room for swelling).

http://www.a123systems.com/products-modules-energy.htm�

Jan 27, 2013

JRP3 The A123 pouch cells, and the Volt cells, are strapped together with thin cooling plates between them, I don't see any room for swelling, which should not be taking place as far as I know. Certainly we strap our LiFePO4 prismatic cells together with no room for swelling. A swelled cell means something went wrong. Since LiFePO4 cells, including A123, have lower effective internal resistance they don't heat up as much during use, and can put out much higher C rates. Yes the Fisker A123 cells have thin aluminum plates for cooling, but the newer A123 EXT cells are supposed to be even less affected by temperature. Since they don't heat up internally as much during use a less aggressive system might be used to keep the pack protected from external high temperatures, for example just circulating cool air around the pack perimeter. Also remember that in the Fisker the small pack is working harder, with a Model S sized pack I'd bet the A123 cells would be very lightly loaded compared to their potential.�

Jan 27, 2013

arg Some of this may be their way of achieving passive safety. I remember a long time ago Tesla putting out some demo photos where they had deliberately put one cell into thermal runaway (ie. on fire), but it didn't spread into the rest of the pack. Smaller cells obviously helps with that (less energy in the initial failure scenario), plus a degree of spacing between them.�

Jan 28, 2013

strider As for the IP arguments, I recall reading here that Tesla has EVs from their competitors torn down in their labs so they can't be hypocritical about this. Even if I hadn't read that here I would assume it would be true as every company in every industry does this. It's a part of doing business and any company that doesn't know what its competitors are doing is not going to be around long. Much of this is way over my head but I like reading about it and looking at pretty pictures.�

Jan 28, 2013

doug And yet Tesla still has the most energy dense pack.�

Jan 28, 2013

JRP3 Yes, with lots of room for improvement, literally.�

Jan 28, 2013

rcc That's because Tesla is riding the commodity battery curve. Consumer grade usage patterns will continue to push commodity batteries towards a combination of greater energy density, reasonable weight and lower cost at the expense of lower lifespan and lower reliability (unless carefully controlled) than desired in an aircraft, automobile or other "enterprise"-equivalent application.

Tesla is successfully using commodity cells in an enterprise application by taking on the job of making the battery pack behave reliably itself. As opposed to folks who use batteries like A123. They are basically delegating the problem of how to make the battery behave to A123.

Tesla's approach is harder but the advantage is that because you're designing both the battery pack and the car to work together, you can make the car accomodate the battery pack (and vica-versa) in ways that otherwise aren't possible or practical if two manufacturers are designing each part on its own.

By doing so, Tesla can ride the commodity battery curve so they'll always have the cheapest, densest, most cost-effective battery packs.

The Model S is basically their 2.0 version of a vertically integrated powertrain and battery-pack combination. They've got a big head start on anyone else who might want to try the same approach.�

Jan 28, 2013

dpeilow People have been saying that Tesla's battery technology is somehow sub-standard for as long the Roadster has been out (remember Finkenbush?). Well guess what, they are still way down the road on everyone else.

If there is room for improvement, let's see it.�

Jan 28, 2013

JRP3 I think we are all counting on the fact that there is room for improvement.�

Jan 28, 2013

stopcrazypp Room for improvement in packing cells closer? Or room for improvement in cell density (which is happening naturally even without Tesla, for example the NCR18650B offers 3400mAh now)? Maybe both?

- - - Updated - - -

There's a discussion in EVTV about the need for expansion room for pouch cells, but it seems it was not conclusive (Jack does say A123 doesn't expand unlike other pouch cells and that the issue of flexing is a bigger concern). I take your word and Jack's that there is no need for room for expansion, but obviously the cooling plates take up space.

http://jackrickard.blogspot.com/2012/02/this-week-we-continue-our-obsession-on.html

Anyways, given the relative densities of the cells, Tesla still can afford to leave a significant amount of free space for cooling and still have the most volumetrically dense pack.�

Jan 28, 2013

JRP3 Yes both. I'm expecting at some point higher density cells, but cells with better temperature tolerance, improved electrolytes, should allow tighter packing with little to no active cooling. I'm not aware of anyone cooling the LiFePO4 cells we use in our conversions, even in warmer places such as Nevada, with no signs of capacity loss after 3+ years. If cooling is less of a concern and cell level safety is better, and production volume of pouch cells increases enough to get a price per kWh near that of 18650 production, then we don't need to have all that empty space and cooling channels. For now they are a necessary evil, but I don't expect that to always be the case.�

Jan 28, 2013

KD5MDK I think one of the ideas is that if you run a Model S for 150k miles or whatever and essentially kill the battery pack, at that point you can swap in a new one and have a car which is a lot closer to Good As New than any ICE would be.�

Jan 28, 2013

Laumb Its not just for cooling, but also to keep the pack toasty at winter. Expect to see the "cooling system" stay put for a long time.

_____

Tapatalkin' from iTalatut.�

Jan 28, 2013

mitch672 I can corroborate this, when I plug in, you can hear the "heating system" spool up, to heat the pack before charging starts, it's been between 19-25 degrees here, I know a regular heat wave for some countries, but cold here. The pack doesn't like charging when it's cold, in fact I keep the car plugged in to a 120V outlet in my parking garage, the main purpose is not to add range to the car, but keep the pack warm, so regen and power are not limited for the drive home, it adds a few miles as well, but that's not the reason to plug it in at work.�

Jan 29, 2013

JRP3 Other chemistries are less sensitive to the cold, as well as heat, and there are other ways to heat a pack. I do expect that design to remain for a while but I also expect to see it eliminated at some point.

Look at the A123 pack assembly, tightly packed cells with thin aluminum heat sink fins between groups of two cells. I would bet that in a larger pack where C rates would be ridiculously low compared to what the A123 cells are rated for those heat sinks could be eliminated.

�

Jan 29, 2013

neroden This is really important, actually. Tesla should advertise this fact, because *this* is why we don't have to worry about battery fires in Teslas. Each cell individually fused....�

Jan 30, 2013

HVM "Large cells without enough space between them to isolate against the cell-to-cell thermal domino effect means it is simply a matter of time before there are more incidents of this nature,"

Elon Musk: Boeing 787 battery fundamentally unsafe

:biggrin: (And then JRP3 post a video of "better design" from company under chapter eleven ;P )�

Jan 30, 2013

JRP3 Space between cells is necessary if using a chemistry that runs hot and is more prone to thermal runaway. Using a chemistry with low effective internal resistance that doesn't contain it's own O2, not so much :wink: As for A123 bankruptcy, poor management has nothing to do with the parameters of the product. Tesla has the best design for the current chemistry they are using. I hope in the future it won't be necessary.�

Jan 30, 2013

AnOutsider Further discussion re: Boeing has been moved here.�

Jan 30, 2013

JRP3 Not a proper move since my post was directly relevant to this discussion, and is now out of context in the Boeing thread. My post did not even mention Boeing.�

Jan 30, 2013

AnOutsider Apologies. I thought your original post quoted DSM. It doesn't appear to now.�

Jan 30, 2013

JRP3 Thanks for the correction.�

Jan 30, 2013

HVM Yes, like big* and safe A123 cells:

"Another example is the A123 Prius: an aftermarket Prius conversion using �safe� A123 cells caught fire while in use, and burned to the ground a few minutes later. The ensuing investigation found that a loose electrical connection generated intense heat, causing a nearby cell to fail catastrophically. The propagation from cell to cell was not contained and the entire vehicle burned down. Hopefully Fisker has been more diligent with the protection of its A123-based battery system."

from http://www.greentechmedia.com/articles/read/Guest-Post-Disparities-in-EV-Battery-Philosophy-Teslas-Hidden-Advantage/

*(ok not so big)�

Jan 31, 2013

JRP3 Sorry, those were actually small cells, similar in size to what Tesla uses, not large format cells. And as your link states the cause was a loose connection that caused arcing, not an internal overheating condition. Just about any battery can catch on fire if you create a high resistance path and continuously pass current through it. Worth noting that in this case only a few cells out of the whole pack actually burned. Even though there was no space and no cooling the fire did not propagate through the whole pack and did not lead to full thermal runaway. Full report here, jump to page 11 to see the burnt pack if you don't want to read the whole thing.�

Jan 31, 2013

HVM You're right, those were small cells. And no, not the all cells catch fire. But that makes no difference to out come: car burned down.

(ok you don't need drive pack for fire, 12V is plenty enough, as Fisker now knows)

Linked investigation report is good read to anyone in this thread, showing a bad design compared the good design in the first post...�

Jan 31, 2013

Ingineer I built a pack of 864 of the A123 26650's for my own homebrew Plug-in-Prius conversion. They are amazing cells! There is so little temperature rise, I didn't have to implement a cooling system. I've never seen them rise over 110 degrees, even after parking in the sun (hot car) and then pulling about 4C from them until dead. They are rated to handle 30C continuous discharge and 52C for 10 second pulses, and can routinely be charged in 15 minutes. After over 2 years and hundreds of cycles they still have MORE than the rated capacity. The only downside to them is they are expensive and relatively low energy density. But the savings and reduced complexity (for me) of not having a cooling system is a big plus.

The failure mentioned above was due to poor assembly techniques, I've never seen an A123 26650 fail.

-Phil�

Jan 31, 2013

JRP3 The car could have burnt if no cells at all had burned. A high current short can set fire to other vehicle components, as probably happened in this case. Probably the plastic battery cover was the first thing to ignite from the heat.

Exactly.

If the connections had been properly tightened the design probably would have been fine and no fire would have ever occurred.�

Jan 31, 2013

stopcrazypp A "good" design would not assume that. And in this case that assumption was clearly wrong. Like what the Boeing engineer said, you assume things can fail every step of the way (even if you designed them not to fail).�

Jan 31, 2013

JRP3 I'm not saying the design could not have been improved. However if one of the high power connectors from the Tesla battery pack to the inverter was not tight and developed high resistance during use the same thing could potentially occur, unless each connector also has it's own temperature monitoring device that can cut the power, and it's functioning properly. The main point I think is the A123 problem was not a runaway pack fire. Cells in direct contact with other burning cells did not ignite.�

Jun 5, 2013

Ingineer Anything can be dangerous! I used A123 26650's in my own Prius PHEV conversion. I've never had any concern about them, even using plastic covers for my pack. Of course it's well constructed and carefully monitored.

Any system using almost any type of high-power battery pack can burst into flames and burn if it's not well designed, or it's subjected to parameters outside of the design envelope.

-Phil�

Nov 21, 2013

Stuart1 The limitation on the 0-60 time is actually traction. If you put normal tires on the P85 you would not get the same 0-60 times. To accelerate even faster then the P85 you would need softer tires that would last an even shorter period of time, more weight on the rear tires (ie like the Roadster), 4 wheel drive, or much wider tires. Only with more traction would more horsepower gain you anything.�

Jan 13, 2014

Constantine more details here

Patent US8393427 - Vehicle battery pack ballistic shield - Google Patents�

Jan 13, 2014

ThosEM Wow, wow, wow, wow! What a find! Thanks so much for posting this. It becomes clearer how to swap a 500 kg battery out the bottom of a car in 90 sec.

;=)�

Jan 17, 2014

Constantine You're welcomeThere are a lot of awesome things Battery inassignee:"Tesla Motors, Inc." - Google Search

�

Apr 22, 2014

Kitt So the MOdel S really uses 3100mah cells? Genious. That is the breakthrough for e-cars. Compare that: 140wh to 240wh. Almost 100%.

And the battery pack. Also genious. Awesome. 8000 cells stored away without affecting cabin space. And enough space for cooling.

This car is just awesome. Now we only need a 1300kg version of it. Then you would only need 50kwh(200kgcells) to drive 400km.

Certainly possible. I have a document here that says that the drivetrain of an Audi A2 weighs 483kg! An A2 weighs overall 1000kg.

http://de.wikipedia.org/wiki/Audi_A2�

Apr 22, 2014

Skotty

I think this is only partially true. It's probably true from about 0-20 MPH. This would be consistent with my 2011 Mustang GT rated at 412 HP and 390 lb.-ft. of torque with 0-60 of 4.5 seconds and 13.0 quarter mile (this was my baby for about 2 years until the electrification of the automobile became a reality). And it only had 235/50 R18s stock. With traction control off, it generally wouldn't break the tires loose after about 20 MPH, if I remember correctly. I don't think the stock Mustang GT tires were any softer than Tesla P85 tires.�

Không có nhận xét nào:

Đăng nhận xét