Mar 3, 2015

ecarfan That is an interesting perspective. I was struck by this text:

" Each of these businesses - electric cars, road trip recharging, grid storage - could bring Tesla several tens of billions in revenue and many billions in annual profit, should Tesla gain a major player position in the respective market. Success in even one of these businesses would deliver valuation far beyond the current price."

As enthusiastic as I am about Tesla's long-term prospects, I do not see "road trip recharging" as a revenue stream for the foreseeable future.�

Mar 3, 2015

jhm I agree recharging not being a revenue stream. Actually, do not see it as a revenue stream for anyone after about ten years. Electricity is too cheap to sell-per-charge. Rather it can be much more valuable as a marketing inducement. As retail becomes increasingly virtualized, marketers will pay a premium for marketing inducements that can draw customers to specific locations. Right now that is exactly what propels the Destination Charger program. Hotels and other destinations are willing to provide free charging as an amenity or inducement for customers to patronize their business. An apt analogy is free wifi at cafes. It's provided free because it attracts customers. So my prediction is that within ten years free charging will be ubiquitous. Of course, there is room for companies like Tesla to innovate charging solutions that businesses will pay to provide to their customers.�

Mar 3, 2015

palmer_md It can be a revenue stream if another manufacturer decides to put supercharger hardware into their vehicle. They'd get possibly $2500 per car that has access to the network. I think that eventually some other car company will opt into the Supercharger network.�

Mar 3, 2015

vgrinshpun That is why Tesla is not using this model :smile:. They are having revenue by charging a one time fee.

I think that by the time other automobile manufacturers decide to build compelling electric cars, rather than just compliance cars, they will fall so far behind, that the only sensible way for them to make a switch (and stay in the business at all) would be to license technology from TM, especially because by that time TM will have global SC network that allows convenient road tripping. Buying into the SC network would most likely require a one time fee, similar to the current model.

If Google and/or Apple decide to enter the automotive space, it will make a lot of sense for them to buy into the SC network as well. Once again, one time, per car fee model can be used by Tesla to obtain a revenue stream.�

Mar 3, 2015

renim If the other manufacturers created alternate standards to compete with the globally consistent and free Chademo standard, why would they be motivated to pay Tesla $2500, when they don't even want a free standard?

They (automotive SAE Combo backers - don't want EVs, they sure don't want to pay someone else for use of charging standard, PHEVs will suit them just fine.)

I could envisage Renault or the Chinese using Tesla SC, and higher cost cars like Koenigsegg etc�

Mar 3, 2015

32no Kimbal Musk just tweeted/instagramed multiple pictures of the Gigafactory. In one of his captions, he mentions that Phase 1 is 1.7 million square feet. This is much larger than the results of the speculative calculations that some of us were doing earlier.�

Mar 4, 2015

RobStark

Tesla's current cell cost is believed to be less than $160/kWh. That corresponds to a unit cost of $1.95 for each 18650 cell capable of storing 12.2Wh.

http://articles.sae.org/12833/

The Panasonic cells purchased by Tesla are specifically designed for the automaker and feature a Tesla-patented vent system within the end cap. Battery supplier sources who spoke anonymously estimate Tesla�s cell cost per kW�h to be less than $160.

I have never seen a quote this low.�

Mar 4, 2015

jhm You guys are right about other EV makers potentially buying into the Supercharger Network. This could be for a fee like $2500 per car or for an agreement to install and maintain a certain number of stations and stalls per 1000 new vehicles sold. In the later case, money would not pass hands from SC partner to Tesla, but the network would be expanded and paid for to the benefit of Tesla's customers. But to underscore my thesis, in either case you have businesses supporting nominally free charging because it creates value for their customers and helps sell more product. So this is what I call marketing value. Right now, I believe Tesla is the leading company extracting marketing value off of nominally free charging both with Superchargers and Destination Charging. So they are leading the way, and I am merely extrapolating how many businesses will eventually want to tap this marketing value for their own customers.

BTW, if Tesla ever wanted to hire me, I would love to develop a whole marketing program essentially to make charging free, fast and ubiquitous for everyone. So Elon, send me a PM, and we can talk.�

Mar 7, 2015

wk057 I'll just leave this here

Gigafactory Drone Pics�

Mar 9, 2015

tom66 I'm confused by "Gigafactory pilot" and 20% of full size. Are we seeing the full size GF that Tesla were talking about in the initial PDF, or just what they can get online by 2017?�

Mar 9, 2015

ScepticMatt the latter�

Mar 9, 2015

tom66 Cool, so it will be interesting to see the final factory. I would guess they intend to bring the rest online by 2020 or as orders reflect, wonder how they will manage upgrading the existing facility without too much disruption.�

Mar 9, 2015

mpt Tesla Gigafactory progress in jeopardy? Maybe? Tesla Fiercely Denies Rumors of Gigafactory Slowdown With Gigafactory Field Trip for Board of Directors - Transport Evolved

I looks like it's inconclusive as to why the factory is quiet - perhaps a supply hitch?�

Mar 9, 2015

uselesslogin It looks inconclusive as to if the factory is quiet. That is such a weird article. First it says they did the March 3rd field trip to counter negative press. Did Tesla get a heads up from the press that the negative press was coming on the 6th? Second, in digging through the links I see a photo from January with a full parking lot, I found one from February 26th with a not-so-full parking lot. And now the recent one with also a not-so-full parking lot. The one thing I think I see in the 3 photos is progress. The frame seems to keep getting bigger. So am I missing something here? Can someone lay photos together from different dates to show a slowdown in progress of any sort?�

Mar 9, 2015

mpt Bob Tregilus is on the ground there, I'd say his input, well, sense of activity, is probably the most compelling piece of evidence. He's photographed empty parking lots in the mid-day. Just seems like a tell of something.�

Mar 9, 2015

JRP3 It could be simple ebb and flow of construction. That's certainly the way many projects around here seem to progress. A lot of activity for weeks, then days/weeks of nothing, then activity again. Maybe they are waiting on key components.

- - - Updated - - -

Article by Randy Carlson on SA with comparative pictures he took. http://seekingalpha.com/article/2982946-teslas-big-battery-building-doom-or-progress

End of Jan

This Sat

�

�

Mar 13, 2015

Joel BYD is ramping up production:

China's BYD takes aim at Tesla in battery factory race - Yahoo Finance�

Mar 13, 2015

jhm Good to see this aspiration. They author tries to make an equivalence to the Sparks Gigafactory at 35 GWH cell capacity, but fails to recognize the full 50 GWh supply chain capacity.

Even so, if BYD can grow capacity 6 GWh per year, that would be a tremendous advance for the industry.

I also wonder if we'll see the stationary storage market heat up. The rest of the auto industry is doing little to create the demand needed to rapidly and massively scale up the battery industry. If the stationary market takes off, that could drive massive scale up, production efficiency, and technology advancement. This would build up an industry that is capable of supporting the transition to EV dominance in the auto industry, even before automakers are fully committed to this path. Thus, stationary can prime the market for sustainable transport.�

Apr 19, 2015

jhm Tesla's gigafactory is coming together, thanks to satellite images

New satellite image. Hard to tell how this compares with other recent images. It seems the construction is much longer.�

Apr 19, 2015

austinEV Won't be operational until 2020?�

Apr 19, 2015

dhanson865 They just missed the word "fully". Earlier in the article they say:

It'll start producing well before then, just won't be completed and producing full capacity until much later.�

Apr 19, 2015

32no Based on that satellite image, I estimate that the section currently under construction (with beams laid out) is 420 feet wide by 2050 feet long, or a total of 861,000 square feet on one floor, which is 1,722,000 square feet on two floors. Kimbal Musk tweeted that it is 1.7 million square feet about a month and a half ago.�

Apr 20, 2015

jhm Super! And when we're counting both floors, we're looking at 10Msf total, right?�

Apr 20, 2015

Trev Page Tesla said the current pilot structure is only 20% of the total finished Gigafactory size 10m square feet is on two levels. I hear concrete flooring has started so close up should be soon after that. Start or machinery installation will happen later this year and into early next year. I can't remember where I saw documentation but I did see leaked PDF files showing first cell production was going to July of 2016. If I find them I'll post them.�

Apr 20, 2015

jhm Sounds good. 17% is really close to 20%. Soon they'll be calling up the IBEW union hall to send out the electricians!�

Apr 20, 2015

Auzie Couple of interesting attachments, most likely not up to date but still reveal the thinking behind this project

From TM, Gigafactory

Slides show batteries recycling process feeding back into raw materials and production start in 2017

Agreement Panasonic, TM

One of my old posts that I can not locate had a better pdf attachment, outlining the agreement in more detail�

Apr 24, 2015

evp Here's a pic from this week. Looks to me like most of the structural steel is up. I didn't see much activity, but it was 7:30 in the evening. Most of the construction equipment that was parked there in this picture http://www.tweaktown.com/news/44649/teslas-gigafactory-coming-together-thanks-satellite-images/index.html was gone.

�

�

Apr 24, 2015

jhm Are the cranes gone?�

Apr 24, 2015

rtz I'm surprised whatever they are going to skin/wall the building with isn't on site.

Also it seems like for projects that big; they usually mix concrete on site?�

Apr 25, 2015

Krugerrand I'm going with: they like to keep the site spic and span. :smile:�

Apr 25, 2015

dhanson865 apparently rust isn't a concern with all that uncovered framework.�

Apr 25, 2015

Foghat I think the recycling piece doesn't get enough attention. I feel it may be the next really revolutionary step in sustainable transport as well as dramatic cost reductions in vehicle production. JB straubel noted that none of the materials are expended once the pack has reached its useful life. It is just a matter of rearranging atoms in his estimation. Hence, the idea of recycling old batteries and creating new ones from the same materials. I imagine it will be a good twenty years or more before irecyclying in this wayis truly able to see scale, but how incredible would it be if tesla didn't require nearly any new raw materials mined from the earth anymore? They would just take old packs and reprocess them into new ones. Costs in many areas would plummet. So, much innovation coming its mind boggling to me.�

Apr 26, 2015

chickensevil Its the desert not like it rains much, haha�

Apr 26, 2015

ecarfan Steel will still rust/oxidize in the Reno climate, since there is always some moisture in the atmosphere, but the process will occur more slowly than in a more humid climate.

I'm sure the building designers and construction project managers have taken that into account.�

May 1, 2015

Benz Business Insider UK:

"Musk said that initially the Powerwall and Powerpack will be made in Tesla's Fremont factory, but as the product line scales, it will be made in the massive $5-billion Gigafactory that the company is building in Nevada.

And there will be many more Gigafactories, Musk said."

Did anyone actually hear Elon Musk say this?

I dis not watch the livestream of the battery-event last night.

Here comes Tesla's 'missing piece' battery announcement - Business Insider�

May 1, 2015

blakegallagher Yes he mentioned that the gigafactory and powerwall and powerpack would all be open patents as well. He envisions many different companies building them all.

I am not 100 percent positive The words you used were his exact words but he made it very clear there will be many.�

May 1, 2015

MikeC Yeah, he referred to Reno as "Gigafactory version 1" and went on to talk about the need for many gigafactories.�

May 1, 2015

DriverOne I didn't understand what Elon meant by thinking of the factory as a product, this is version 1. That makes it sound like they will be selling gigafactories? They can't be selling the design, that's open sourced he said. Can someone help me understand?�

May 1, 2015

Gerardf As I recall he stated GigaFactory 1, not version 1.

You can check here : Elon Musk Debuts the Tesla Powerwall - YouTube scroll to time 15.35.

Correction, at 16.20 he also states version 1. However I have the impression he meant the first GF, not version.

�

May 1, 2015

pr0teu5 i think this quote is about how they're approaching the design of the factory, not the marketing of this. Rather than thinking of it as a traditional factory they're thinking about it as a giant machine made for the purpose of building factories. So when new versions of the gigafactory come out they should be radically improved in the same way that second generations of machinery are improved. In many cases when a sucessful factory is built new versions are simply carbon copies of the old one. This won't be the case with the gigafactories.�

May 1, 2015

chickensevil The way I took it... anyone could technically make their own factory. Nothing is stopping them. Just the same as you could go and do all the painting, building, electrical work, etc, if you were to build your own home. Yet instead, most people will hire people who have the expertise and experience to do that work for them. So the factory-as-a-product, to me, would mean that Tesla would provide their "services" in helping people establish their own gigafactories.

That was how I understood it at least, maybe I am thinking wrong here.

Because the factory isn't just a factory... This is a self-contained thing. It will make it's own power and use that power to turn lithium, cobalt, nickel, etc into a completely finished battery pack for whatever purpose it is being designated for. raw materials in and consumer level finished product out. All without being dependant on the grid, and without impacting the environment in harmful ways.�

May 1, 2015

dhanson865 I think what he means is:

1 Global battery production will ramp faster than Tesla can possibly finance

2 Tesla has the best battery production setup

3 He'd rather see all the other new battery factories down the line be like his instead of worse

4 He is putting his money where his mouth is and making it possible for another company to not just reinvent the wheel again to make their battery factory. They can do something better than just mimic him, they'll have access to plans detailed enough to copy exactly.

If they offer to pay consulting fees he might be willing to accept the money but I think he is also just willing to let execs (plus their team) from large corporations tour his facility and copy exactly without paying.�

May 1, 2015

Foghat Elon was saying they will get better with each gigafactory iteration, just like the battery, each gigafactory will be better then the last. Production costs will further go down as well as improved

machinery/robots products will come out: gigafactory as product.

So, each gigafactory will be a next iteration product of tesla mind trust. Like iPhone 1 thru 6, gigafactory 1, 2, etc... This will be for tesla owned gigafactories as well as contracted services for other company's Gigafactories. This also may include tesla mass producing gigafactory robots and other associated machinery unique to battery production... Gigafactory as product...

I think Elon was giving a hint toward another business opportunity: mass producing and selling robots and associated machinery (and intelligence/software service & sales). If hundreds or thousands of gigafactories are going to need to be built to satisfy global demand, this could turn out to be a massive revenue source. Now, I'm getting the feeling this was Elon's under the radar "one last thing" from last nights unveiling.

Tesla Robotics as the next new product line??�

May 1, 2015

Foghat Holy crow... They could also have a cloud based knowledge center that pushes software updates to all machinery in every gigafactory around the world with improved production techniques or new production techniques, instantaneously resulting in improved production costs and quality through the push of a button. Imagine the implications of time saving interation implementation across entire global manufacturing across all industries... I guess Tesla robotics could be bigger then just battery gigafactories.

Now I know why AI is such an immediate concern for Elon... He might be the one to "summon the demon" if not careful in how he implements this.�

May 3, 2015

jhm Gigafactory Financial Modeling

The gigafactory-as-a-product concept is very intriguing. I would encourage people to revisit the gigafactory financial modeling thread for tools on how to value this. In particular, the off-take agreement concept is relevant to effectively leasing a portion of a GF. Consider Oncor's intent to buy 10 GWh, they may actually do well to structure the deal as an off-take agreement.�

May 3, 2015

MSEV TeslaRobotics.com is already taken by someone...�

May 3, 2015

Cattledog I have teslamodelx.com but no one has called me to ask if they can have it.�

May 3, 2015

ecarfan And what was your motivation for registering that? http://teslamodelx.com/�

May 3, 2015

Cattledog I started a blog about my ownership experience with Model S, tried to get teslamodels.com but it was already registered, so I then just created one on wordpress that's in my signature. I was pretty active in it for the first couple years but have admittedly waned the last year. I got teslamodelx.com at the same time thinking I'd do the same when I got my model X (which was forecast by Tesla as 'late 2013' at the time). Still waiting for the car so the blog has never started up.�

May 5, 2015

chickensevil Not really the best thread for this, so I'll post the longer discussion over on the website discussion section... but suffice it to say, someone at Tesla had registered something like 600+ domain names starting from like 2003 all the way to current with the vast majority happening in 2007 and 2014. The old registered email address for all of them was [email�protected]... I say it in the past tense since it has all changed now to [email�protected], which was likely in light of the recent social engineering attack and DoS/Defacement/DNS Hijack/whatever-you-call-it... Anyway, I'll post more details over in this thread: All Discussion re: Tesla Motors Website Forums�

May 10, 2015

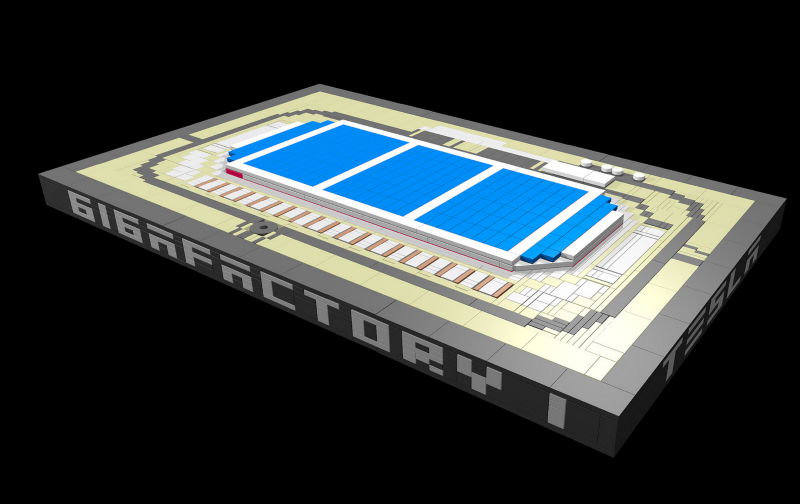

FluxCap Charming Lego Gigafactory rendering, via Reddit:

Lego Tesla Gigafactory No. 1 | Flickr - Photo Sharing!

�

�

May 10, 2015

AlMc Is this the 'original' design or the one that needs to be 20-50% larger with the introduction of stationary storage? :wink:

Thanks for posting.....just having some fun on mother's day.�

May 11, 2015

VolkerP 50% larger means, they must add one floor.�

May 11, 2015

jhm That's a cool idea. I suppose that would do it from a floor space point of view. I would expect that the plant will be laid out with lots of parallel production lines. So if the dimensions are already optimal for the length of a production line integrating first and second floors, then a third floor might throw this off. So they may need to make it longer in the dimension that sets out more parallel lines.

From the outset I have wondered if they simply anticipated the need to build out multiple GF building in this same campus. If so, the extra capacity could just be half of another building. It will be interesting to see how this works out.

Has there been any reaction from Nevada? This could mean another 3250 jobs for the area. Take that, Texas Auto Dealers.�

May 12, 2015

vgrinshpun If foundation/structure can bear it, it would be better to add two floors, even if one floor kept vac and for a while. Incremental cost would be very reasonable.�

May 13, 2015

hobbes Hm... don�t really believe they are going to take the roof off that was already built.

Seems more likely to me that they�ll add more to the sides, as the building is meant

to be modular in that dimension anyway as far as I understand.�

May 13, 2015

AlMc I am not an engineer but adding height (weight) may not be feasible based on the load handling ability of the steel already in place. I suspect expansion is as you have predicted.�

May 13, 2015

Theshadows Building code wise there is quite a difference between three floors and four.�

May 13, 2015

pmadflyer Civil Engineering student here. when designing a structure, one takes into account the forces of maximum predicted loads and load combinations (ex: wind + rain + dead load + live load + earthquake), and then designs a structure that can withstand all load cases plus a safety margin. This is because steel is never uniformly strong, a column that is cooled or handled slightly different at the mill might already be stressed before even being erected. While these safety margins might allow a third floor to theoretically be supported, there must still be a certain safety margin above this to meet code.

It is likely that the factory will be extended horizontally or utilized differently within the currently planned dimensions rather than vastly increasing cost to build higher vertically. As said above, once you start going up, the code requirements, and construction costs sky-rocket. It's far easier to lift more steel 72 feet vertically (GF roof height), than it is to lift the amount of steel needed for another level an extra 35 feet. Since the steel required to support the extremely heavy equipment is already so large, the added height and weight would require larger cranes and more critical picks. larger cranes, with more line parts (more pulleys) are also slower, and more expensive to operate.

If I recall correctly, Tesla bought an extremely large piece of land, far larger than the factory. Perhaps some will be utilized for large satellite factories, in addition to the satellite factories that may be run by suppliers on the GF land (pad already cleared nearby for this purpose).�

May 13, 2015

favo From Tesla posts 30 job openings for gigafactory

�

May 15, 2015

c041v I'll try to knock off a few at once;

I doubt they could find cranes big enough to economically add another floor. Land is cheap, they'll build outwards.

Concrete is sometimes mixed on site, but I would doubt that to be the case here, you'd see a Batch Plant and some Sizable Aggregate piles and given that it's Nevada, probably a facility that can hold/produce ice or Liquid Nitrogen. Local concrete companies do this very efficiently, and besides there's very little concrete work left to do. This is a structural steel building, not precast. All the concrete is under the steel and buried in sand.

Cladding will come in later, it'll probably be thin gauge steel. Not sure what sort of insulation they'll need. No harm for that steel to sit exposed for a long time. Nevada's is nowhere near and ocean and the relative moisture in the air is low. why do you think they store old planes in the desert? Low moisture.

What is a bit puzzling is that their appears to be very little activity on site. I don't see any sort of HVAC/Utilities (Aside from a few sections of pipe) or other Mechanical systems being installed. I would have expected all sorts of things sitting around, especially some of the larger components that can only be installed while everything is open. It all just looks very... quiet and more like a warehouse than a factory at this point.�

May 16, 2015

chateauoaks Hey, Kids, you are all over thinking this. The way you double output is not by expanding outwards or adding a third level.

You double or even triple production by adding a second or even a third shift of workers. This is what they are running the numbers on, not more steel. lol!�

May 18, 2015

Fanatic

From the drone 4k flyover. Concrete work has started and has gone quite a bit. Note color differences and the rebars that has been laid. Looks like the first floor is done in the middle.�

May 18, 2015

pmadflyer Looks like the interior columns are being painted white also.�

May 18, 2015

chickensevil Well thanks for pointing these things out, cause to me it had looked like there wasn't any progress at all from the last time someone took shots of the place.�

May 18, 2015

Fanatic just so big that the progress it's lost within the complex.�

May 19, 2015

kenliles tweet from Elon:

@elonmusk: This is not the full Gigafactory, it is just the pilot plant (1/4 size)

Video: First Tesla Motors Gigafactory Drone Flyover Lets You Explore It in Glorious 4k - Transport Evolved�

May 19, 2015

jhm Gigafactory 0.25, I wonder if this would have 12.5 GWh output.�

May 19, 2015

32no I thought the pilot plant was 1.7 million square feet, or 17% of the total 10 million square foot factory, not 25%.�

May 19, 2015

doggusfluffy I think there are 4 'sections' now and there were only 3 when Kimball tweeted that number.

*I went back to check and it seems it grew wider and maybe a bit longer...

http://i1.wp.com/evobsession.com/wp-content/uploads/2015/03/Tesla-Gigafactory-from-a-distance.png�

May 20, 2015

chickensevil And it looks like they have started foundation work on section 5. It is interesting how sectioned off they made this, like whole separate buildings, but right next to each other.�

May 20, 2015

RubberToe Isn't the idea of "whole separate buildings" a requirement given that they want to start producing batteries from the first building before the second one is finished? You really don't want to start manufacturing in a building that has a gaping hole in one end.

RT�

May 21, 2015

austinEV yeah, they will be independent mini factories, or at least THIS part will be. It could be that this quarter will be independent to get equipment and engineers to work asap to make their end of 2016 deadline and also start learning asap. It is an open question if it will be 4 mini factories, or 1 mini and a 3/4 big factory or something else.�

May 23, 2015

doggusfluffy Using that rectangle pad as the reference...it looks like major progress since the drone video.

https://pbs.twimg.com/media/CA0EuVZWsAAakDS.jpg:large�

May 23, 2015

austinEV What are we going to do with ourselves once the outside is all done and the work is all inside?�

May 23, 2015

Cosmacelf What, you can't fly a drone indoors? �

�

May 23, 2015

austinEV Well you can... relevant xkcd�

May 23, 2015

doctoxics Looks like this picture predates the drone video based on the extent of steel work on the first four sections. Of interest is that the steel work on the fifth section appears to have disappeared by the time the drone video was taken.�

May 25, 2015

dauger A new study by Lux Research showing, even as everyone's costs decrease, how the Gigafactory will extend Tesla's lead in battery costs:

Here's how Tesla batteries will beat the competition - MarketWatch

I find the $/kWh graph intriguing. Two takeaways:

1. Place a horizontal ruler across these graphs, and by my estimate Tesla's prices will be at least 4 years ahead of its competition, e.g., around 2025 the closest competitor will reach Tesla's 2020 $/kWh internal price. Later for others like Nissan.

2. Little differences add up over time, giving Tesla Model 3 higher margins than its competition which Tesla can use to grow production faster than anyone else.

The next decade will be very exciting to watch. Pass the popcorn!�

May 25, 2015

Johan I'd take anything Lux research says with a BIG pinch of (Lithium-Cobalt) salt. They are just guesstimating like the rest of us. If you look historically their prognoses haven't exactly been spot on. They're kind of like those stock analysts who constantly raise or lower their one year price target to be about +20% of the current stock price.

I too could take publicly available data and plot it and then draw linear progression lines in to the future in fancy colors.�

May 25, 2015

daniel Ox9EFD You can't just take X% improvement per year in batteries and assume that trend just continues. You need to look at actual battery chemistries coming up.

There are a few companies doing solid-state Lithium batteries: Sakti3, Quantumscape.

From an interview of Ann Marie Sastry, CEO of Sakti3, she said they will be in consumer electronics in two years, from 2014. So next year. They claim 1100kWh/l (not sure how much that is in kWh/kg), and a $100/kWh target. Of course, I think it was Edison who said the battery industry turns people into liars.

The point is rather, it is hard to project out more than 3-5 years with reasonable accuracy.

Here it is: The Charge of the Battery Brigade - Autoline This Week 1833 - YouTube�

May 25, 2015

daniel Ox9EFD I take back the Sakti3 comment. I couldn't find any information on energy density by weight. I thought I was just missing something but it seems they intentionally did not publish it.�

May 25, 2015

dmckinstry I assume your 1100 kWh/l is a typo. Actually she said 1100 Wh/l. That's still not bad. 1.7 - 4.4 times that of current technology.

But, if it could be afforded, 1100 kWh/l would give us 110 kWh Tesla with a 100 cc battery.�

May 25, 2015

JRP3 As I recall Lux has consistently overstated battery costs, and I'd say they are still doing so with Tesla, though getting closer to the mark than ever before.�

May 26, 2015

daniel Ox9EFD Oops. Yes. 1100 Wh/l. I was thinking about kWh/kg while typing.

Here might be the catch - they did not publish kWh/kg. This might be quite relevant since you could expect an all solid state battery to be heavier than current ones.

It might still be a leap in technology, but we don't know. I sent them a message a day ago asking what is the energy density be weight.�

May 26, 2015

mrdoubleb Didn`t Elon say in one of the recent ER class or on a conference or something that they are already below $200 per kwh? I think it was the same call where he said he would be very disappointed if they would not get below $100 within 10 years.�

May 26, 2015

jhm I wish Tesla would start reporting their battery cost every quarter just like how SolarCity reports their cost per Watt every quarter. It would be good for the industry to know where they stand. The problem with Lux is that they lull the industry into thinking that they have time to wait for someone else to solve their battery problem. The industry has a false sense of security in the status quo. It's time for Tesla to set the record straight.�

May 26, 2015

Zapped Funny thing; I recently saw a similar battery (and better) in the movie Knight and Day�

May 26, 2015

Model 3 It's been reported that their current price (as of their last contract with Panasonic) is $180/kWh for the battery cells. But to Lux's defence - they are talking abut the price for the cells *and* the battery they are enclosed in - including electronics. But still.... �

�

May 26, 2015

mrdoubleb Ok, fair enough.�

May 26, 2015

jhm Right, so Lux is put the non-cell cost of the battery at $5950 for a 85 kWh pack. That still seems steep. Can we break that down a bit?�

May 26, 2015

chickensevil The only way I can see counting a cost that high is some form of amortization of the R&D cost that went into making and designing the pack... Because there is no way I could see Tesla's material costs and minor labor coming in at 70$/kWh not counting the cells. The pack has to cost less than that.�

May 26, 2015

brandude87 Yeah, I'm surprised more people aren't talking about this. I photoshopped a comparison of the Gigafactory using images from February 28 (airplane shot) and May 17, 2015 (4k drone video). You can clearly see that since February, all of section 5 has been completely removed. Why would Tesla do this? Were they short on supplies and needed to focus on completing sections 1-4? Was it due to a design change? Thoughts?

�

�

May 26, 2015

jhm Is it posible that sections 1-5 in the first photo is sections 1-4 in the second photo? It's hard to see definite markers in this.�

May 26, 2015

Gerasimental Using the carpark and incoming road (above section 4 in the 1st image), it does seem that the frame has been removed. As you come down that road to the GF and look right you'd have seen quite a lot of frame in February and just look at empty space now.�

May 26, 2015

brandude87 No, it looks pretty clear to me. I've removed the white borders in the image below to make it more clear. �

�

May 26, 2015

vgrinshpun I think that the spans (11) were removed in conjunction with the planned expansion of the GF, by possibly 50%, mentioned by Elon during the ER. It might be that either the sections breakdown, and/or orientation of sections required changes due to the new increased footprint of the GF.�

May 27, 2015

brandude87 Increasing building size by 50% with such short notice seems a bit impractical for many reasons (cost, time, engineering, etc.), so I think Elon meant that they were going to make the process 50% more efficient. In addition to making the factory more efficient, he probably wants to start pack production sooner than initially planned to help meet demand. My theory is that they halted (and even cannibalized) section 5 so that they could divert all resources to completing sections 1-4 first. This is evidenced by the complete lack of spare beams lying around. Perhaps sections 1-5 were meant to house the core pack production and they found a way to cram it into just 4 sections. This would be consistent with the goal of increasing Gigafactory efficiency. Thoughts?�

May 27, 2015

Fanatic

Seams reasonable enough. Now roofing has been completed on section 1 as labeled in previous posts. More concrete work has been done on section 2-3.. Think its possible they expand the factory by a couple of sections in the future. their site it huge, they will have plenty of land to do it!�

May 27, 2015

vgrinshpun We are all speculating, so in general a lot of things could be plausible. However, given the conversation Elon Musk had with Andrea James during the ER, expanding production by increasing output per the square foot of the GF building is unlikely, as they specifically discussed availability of additional space at the GF Site to expand the building and production because of surprisingly strong stationary storage demand.

I think they are more likely planning for increase of the final building size, and this might require re-calibration of the construction phasing and/or size and quantity of the building sections.�

May 27, 2015

pmadflyer Hey. I was the first person to mention it in the main GF (non-investors) thread. Thanks for making the image though.�

May 27, 2015

brandude87 You may very well be right. If so, the Gigafactory would easily become the largest building in the world by square footage on the ground (footprint), beating out the Aalsmeer Flower Auction building.

Sorry, pmadflyer, I didn't mean to steal your thunder. Props to you for first noticing the removal of the structure in section 5!�

May 27, 2015

adiggs And that is why you put things together with screws and bolts instead of nails

(sorry - been building a chicken coop over the spring and I couldn't resist)�

May 29, 2015

doggusfluffy The striking thing for me about this video is how tiny the massive equipment looks and just how incredibly far away the other end of the jobsite is. I hope the employee breakroom is somewhere near the middle!�

Jun 4, 2015

Fanatic Think this company is quite interesting. They state that in dec 2015 they will increase "monthly production capacity for lithium nickel oxide will rise from the current 850 tons to 1,850 tons." Due to demand of Panasonic/Tesla.

Wonder if they will establish a facility to process the material close to the factory. Read somewhere that the area thats been cleared east of the factory will be the place for a processing plant.

http://www.smm.co.jp/E/uploaded_files/141020-1e.pdf

Elon stated that SMM will have a section in the factory at an interview at MIT last year.

He continued stating that will be a section for Hitachi and SMM then a section for Panasonic at last Tesla would assemble it to packs.

https://www.youtube.com/watch?v=PULkWGHeIQQ

Is it the investment in GF 1 that is implied in this article, not for another one?

https://www.yahoo.com/autos/s/tesla-urges-japanese-battery-suppliers-gigafactory-risk-110000530.html

One can only speculate but if I were to build a GF I would like the suppliers take some risk as well.�

Jun 9, 2015

RobStark Elon just said at the shareholders meeting that production of cells start in the middle of next year.

Previously, it was toward end of 2016.�

Jun 9, 2015

Benz I thought that previously (Q1 ER Conference Call?) I have heard him say Q1 2016?

If that's correct, than this would be a delay of at least three months, right?�

Jun 9, 2015

LargeHamCollider I also had q1 2016 in my head but don't recall the source.�

Jun 9, 2015

32no It was the Q1 shareholder letter:

I think what he meant was that Q1 2016 they will start final stages of gearing up in Phase 1 of Gigfactory 1 in order to start production soon after.�

Jun 10, 2015

jvonbokel Actually I think the "new products" that quote is referring to are the Powerwall and Powerpack. Those will begin production in Fremont in Q1, then expand into the Gigafactory in Q3, which fits with the timeline mentioned yesterday for starting cell production at the Gigafactory in the middle of the year.

Edit: Scratch that, I misread the quote. It is saying Powerwall/Powerpack production starting Q3 2015, then moving to Gigafactory Q1 2016. Seems odd for the timeline to shift by that much in such a short time, but I'd be more inclined to think one was a mistake or miscommunication than that the underlying schedule had changed that much.�

Jun 10, 2015

jjkroll Remember that cell production, at the Gigafactory, does not need to happen for pack production to start. I took this to mean that Powerwall/Powerpack production equipment will be operational in the Gigafactory in Q1 2016. They will use Panasonic sourced cells, from Japan, until Gigafactory cell production comes online later. So they will need to split the cell supply between Fremont and Gigafactory for awhile.�

Jun 10, 2015

jvonbokel That sounds like a reasonable interpretation, and would fit with the various timelines mentioned.�

Jun 14, 2015

MitchJi Hi,

The powerpacks are very similar to the automobile packs. JB said that their profit margin on powerpacks (priced at $250 per kWh) assembled in fremont is about 20%. He then said that the profit margin on powerpacks produced at the GF will be a little better. Two things will reduce the price substantially, economies of scale, "at least 30%", and cells with increased energy density. So packs assembled in fremont cost tesla about $200 per kWh, and with full GF economies of scale, a maximum of $140 per kWh!

Does anyone know at what point the GF is supposed to reach either full or substantial economies of scale? Because maximum price of $140 per kWh, in addition to looking really good for M3 pricing also looks really good for either MS and MX margins, or price reductions.

The problem that drastically superior solid state cells pose for the GF, is that the production process is different as compared to current lithium cells.�

Jun 14, 2015

ggies07 Thanks for the tidbits. If I remember correctly, the full scale is supposed to hit around 2020.�

Jun 14, 2015

32no Where and when did JB say this? Do you have a link?�

Jun 14, 2015

rtz How about an update on the rail link? Can anyone confirm the "end of the line" is still at where the arrow points too? I don't know if that route is certain. Or would they branch off the main line from the north?

Google Maps�

Jun 15, 2015

chickensevil I believe it was stated elsewhere previously that it would be a new branch off from the north. Could be wrong...�

Jun 16, 2015

hummingbird At video link below JB actually said better than $100 per kWh by 2020 (which is only 5 years from now). JB was the keynote at 2015 EIA Energy Conference yesterday talking about this but that video is not yet available ( 2015 EIA Energy Conference )

Here, in early June he said $100 by 2020: (go to mark 36:00)

Elon Musk and JB Straubel share their vision on energy (2015) - YouTube

At $100 per kWh, cars like the Nissan Leaf and VW e-Golf with 200-mile range will hit price point of $20,000 before government subsidies. At that point the utility industry will be completely transformed as well. Pretty amazing.�

Jun 16, 2015

strangethingintheland I note the videos which quote JB Straubel giving the 2020 scenario. However, the reference to the 20% margins was, I believe in the most recent quarterly conference call. And I remember it a little differently. Namely, while we are still making things in Fremont the margins would be modest, but once we transfer assembly to the GF we can expect margins in the 20's.�

Jun 16, 2015

MartinAustin Just a thought... while Tesla Motors is in the business to accelerate the change to sustainable transport (and note, the words "make profit" are not contained in that phrase), the other manufacturers are still in the business to "make as much profit as we can every year." This means, they will price their electric cars as high as they possibly can - and claim that batteries are just darned expensive. If this means pricing them at n-500 where n is the price of a Tesla Model 3, they might do that. If Tesla can't produce enough cars to meet demand, the other manufacturers might be able to get a taste, and buyers won't mind paying n-500.

Something else to watch: Tesla says "no servicing required to meet the warranty." Will the other manufacturers also say this? The dealer-service cartel may be hard pressed to match it.

(sort of OT, apologies)�

Không có nhận xét nào:

Đăng nhận xét