Jan 7, 2015

AudubonB I am finding it hard envisioning a construction site more horrifying than one where a number of PV panels were so strewn about. Please trust Cattledog and others that they really, truly are not solar panels!�

Jan 7, 2015

Zapped You are absolutely correct. Being the business, it's also called Q-Deck

�

�

Jan 8, 2015

ajax

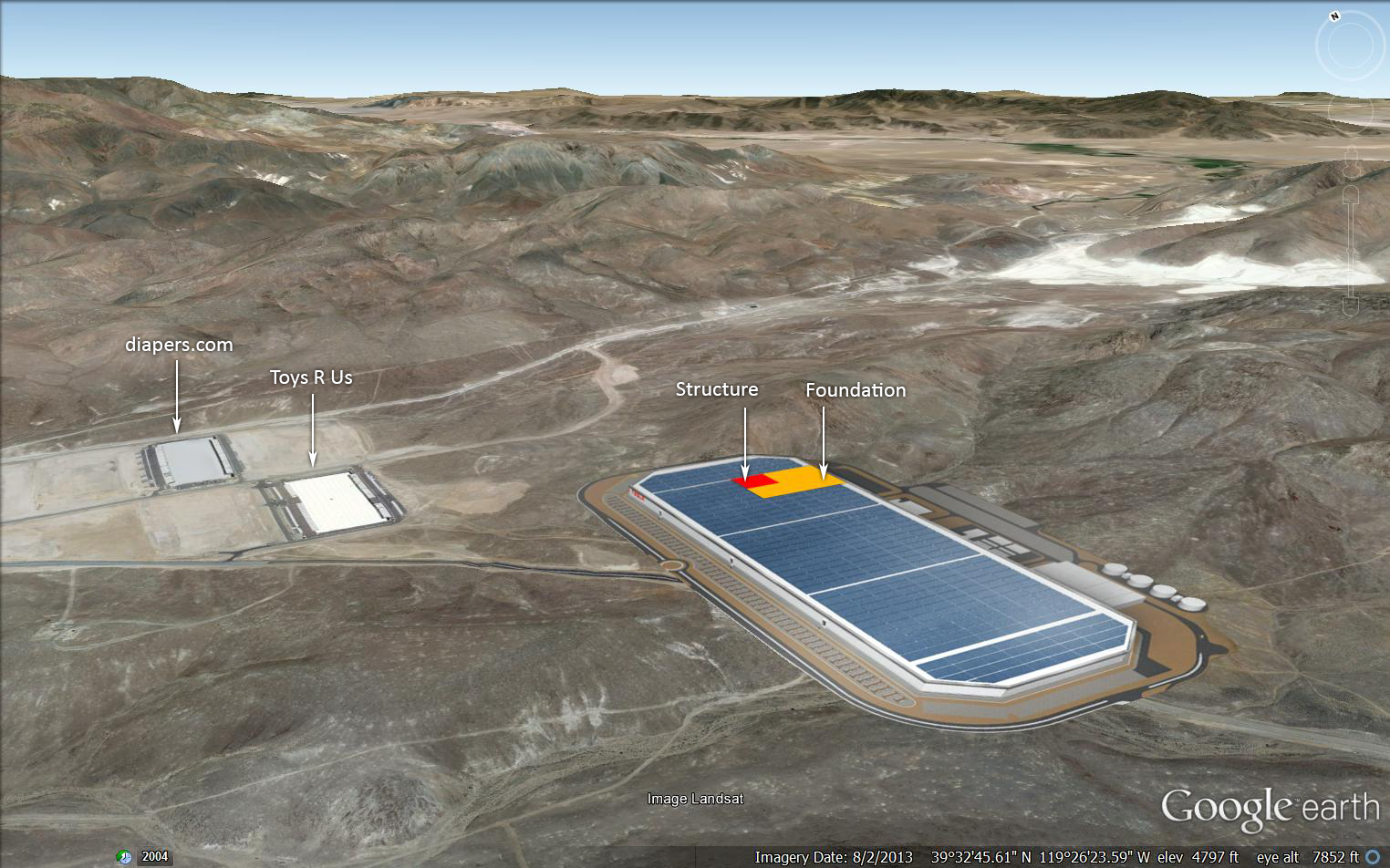

I think it just seems that way because of lens distortion and the fact that a hill is blocking part of our view. This should clear things up:

�

�

Jan 8, 2015

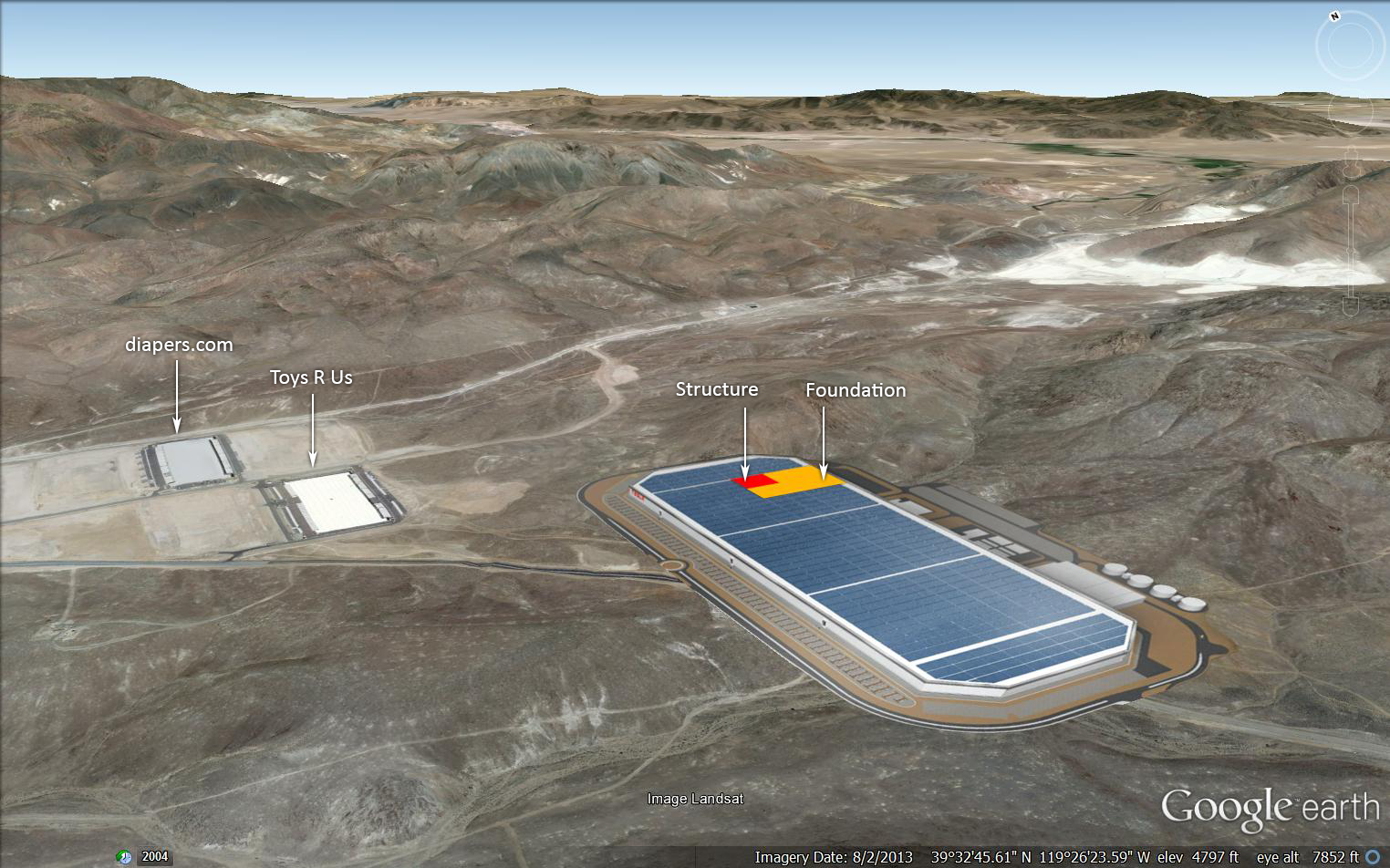

ajax I probably should have included the Gigafactory picture in my post for reference:

�

�

Jan 8, 2015

techmaven Never mind, should catch up reading first.

Great to see progress.�

Jan 8, 2015

Gerasimental In your picture, the long axis of the GF is parallel to those of the other 2 factories, but if you apply the geometry you have there to the actual photo, you get a factory foundation with its major axis perpendicular to the others.

The structure that is already up seems clearly to be parallel to the other 2 factories but this is not the case in your picture.

Unless I'm seeing something totally wrong or the lens effects REALLY mess things up.�

Jan 8, 2015

ScepticMatt The picture was shot facing north-north-west, and the structure is aligned to true north, parallel to Toys R us.

So I don't think your image is quite right. I color coded the two images to help you orient:

(updated)�

Jan 8, 2015

chickensevil I love all of you right now<3

The collective knowledge and abilities of all parties to piece this information together from just a handful of photos... I am just as amazed by people's ability to analyze data right now as I am at the progress of the factory

See, this is what I was thinking it was originally, but then was confused at why they were laying the pieces on the roof in the fashion that they are... When I did roofing (for a VERY short period of my life... I have only ever installed 2 metal roofs in my time, so take that for what you will) when you link the pieces together you almost have to start from one side working your way to the other. But you see random single pieces stuck to the roof all by themselves... and that seems like a very terrible way to build that. I know they aren't likely to get much rain out there... but when it does rain you need them linked properly to avoid any risk of leaks... Unless I am totally missing something with how these particular metal pieces form together?

I too was skeptical of it being solar at this point, but it just didn't make sense to my mind of how they were putting the roof together.�

Jan 8, 2015

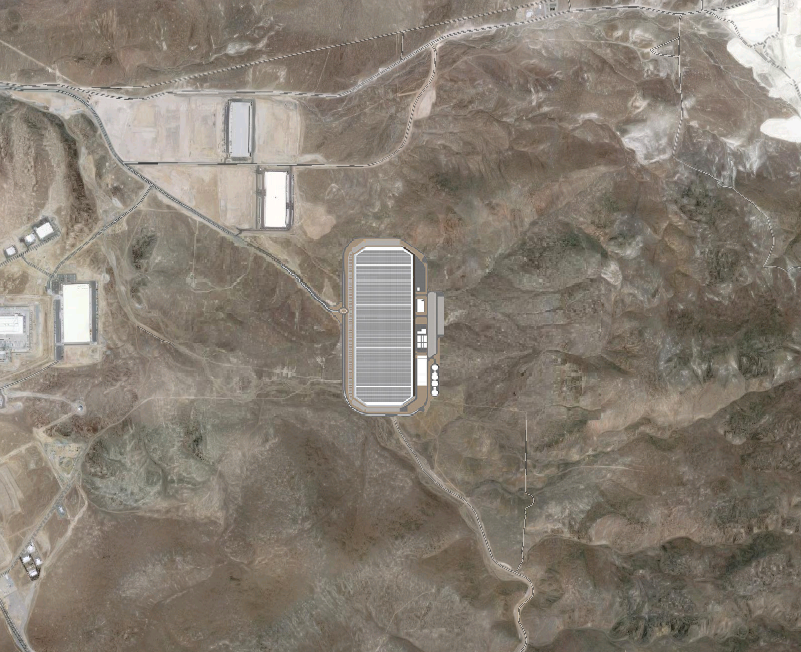

techmaven I'm wondering if the 4 white lines we see cutting across the Gigafactory which break it up into 5 separate sections actually represent different buildings that are co-joined. In other words, will we see one or two of those 5 sections get finished on the exterior and they start putting in the interiors as the next section is built. If that's the case, we won't see the full exterior until say, 2018 or 2019.�

Jan 8, 2015

ScepticMatt Hmm ... you mean something like this?

�

�

Jan 8, 2015

c041v This just made me think of something. Take a look at the other two factories and note the skylights all over the place, which are presumably there to cut down on lighting requirements during the day. I wonder how they plan on setting this up on the GF with a roof that appears to be mostly covered in solar panels. Kind of a catch 22 where you need the panels to harness energy, but those same panels are taking up real estate that could offer free light energy. The rendering does not appear to have accounted for this.

It will be interesting to watch how the Site prep moves forward, as it will be very telling as to how much of the factory they've committed to build in the near term. Thanks to all for the great insight into the perspective and orientation, it's really tough to gauge the current extents.

Also, I believe the white lines in the rendering merely delineate the solar arrays, and not the factory itself.�

Jan 8, 2015

pmadflyer The panels are just placed there so that when the decking gets there, they won't have to walk as far to the nearest stack. With the apparent wide flange beams of the roof structure, it would appear that this decking will have a concrete slab over it. Solar panels are heavy, I'd imagine, so it could just be for accommodation of that weight. Based on ScepticMatt's post, it looks like ajax is right, just on the wrong side of the factory's long axis. I used to post on construction forums, so I might make useful observations occasionally.�

Jan 8, 2015

techmaven

Yes, great drawing!

A number of bears have pointed out that Tesla might not have all the money to build all of the Gigafactory yet. However, nameplate capacity is not expected until 2020 and first cells are expected now in 2016. So do they build the whole exterior, or really do we see a part of the whole thing.�

Jan 8, 2015

pGo I don't think its a bear argument. I strongly feel that Tesla will raise another round once they announce Model 3 and starts taking orders. This year, Tesla will spend a lot on upgrading tools to support Model X lines while continue to grow superchargers, service stations, and stores. Though Elon suggested that they will get more positive cash flow starting with the 2nd half of this year, I think such a case is delayed due to Model X release being pushed out.

Next year, and 2017, most expenses will be directed towards GF where machinery will come in and production lines will be created. A company growing & spending with the nature of Tesla, they need quite a lot of money handy to be capable of unforeseen events like earthquakes which can disrupt manufacturing lines for months.�

Jan 8, 2015

GenIIIBuyer I think you mis-labeled the distances on your black lines, supposed to be other way around? Just from eyeballing the dirt truck in bottom right corner that is at least 30ft long, parked parallel to the 271 foot line, could easily line up 10 of those and not get very far down the line. Thanks!�

Jan 8, 2015

GenIIIBuyer Based on the assumption that each orange foundation marker is 10 yards apart, I am estimating 300 feet by 1500 feet is the black line space. That would be one 'module' of 450,000 square feet. 10 modules with two floors would get them to ~10M square feet. Those distances also line up with # of modules fitting in the other road drawings others have posted above.

------------------------------------------------------------------------------

Updated: Looks like there are only 6 square modules, plus the curved end modules. Either way, I think this photo is taken at a low enough angle that the distance outward is much longer than it appears relative to the distance across.�

Jan 8, 2015

c041v You're right, I think my scale only works in the one plane that the crane is in as the perspective across the other axis throws everything off.

That 30' truck is pretty accurate (Specs sheets say ~ 33' 5") and it appears to be roughly the length of one grid line, of which I count a total of 50 or so. However, I think the perspective is still misleading as if you look at the bays on far left side, you'll notice that they are approximately half of the 50' ones, but are not square, which means that the gridline spacing is probably more like 15'.

*Revised module dimensions working top to bottom and left to right in the picture (Half the black line space)

Top to bottom: 0-50 @ 15' each

Left to Right: A-B @ 25' and B-K @ 50'

750' x 475' = 356,250 sqft per floor or 712,500 per module which equates to about 14 overall.

Hopefully this is a little more accurate? Can somebody get more pictures?!�

Jan 8, 2015

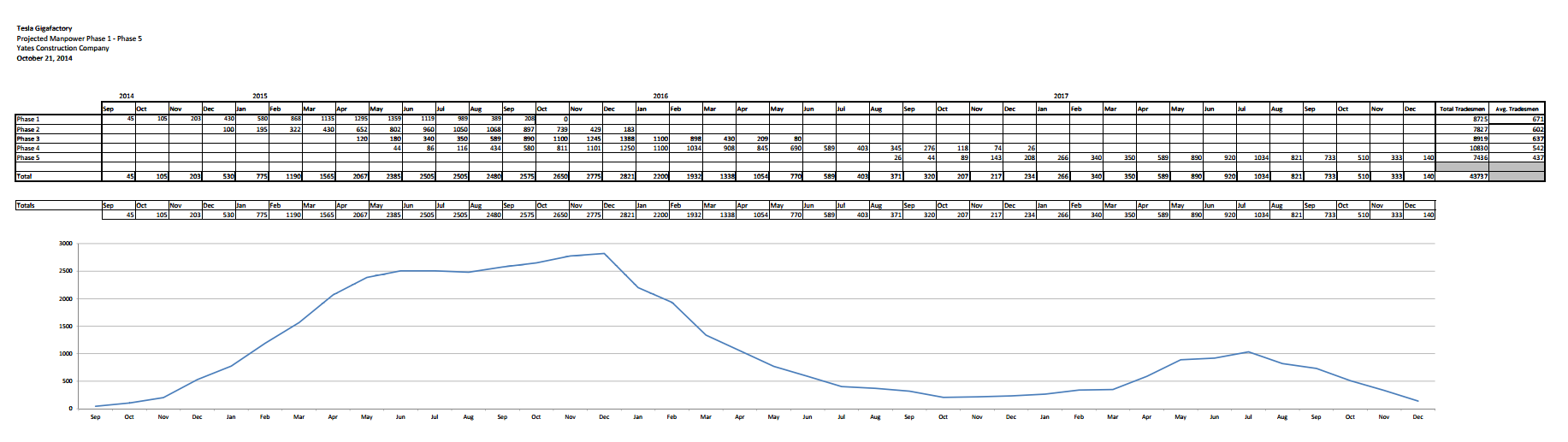

chickensevil I would remind you all of the 5 Phase construction of the project we talked about back on post 1788: Tesla Gigafactory Investor Thread - Page 179

� Phase 1: Sept. 2014-Sept. 2015

� Phase 2: Dec. 2014-Dec. 2015

� Phase 3: April 2015-May 2016

� Phase 4: May 2015-Dec. 2016

� Phase 5: Aug. 2016-Dec. 2017

I estimated at that time that the 5 phases likely represent 5 modules and their completion times. So the whole building will be finished in 2017, but the first module should be up and running by the Sept 2015 and therefore able to start moving in equipment at that point to have production running in 2016. This is all just guesses based on the timelines but it makes the most sense.�

Jan 8, 2015

GenIIIBuyer Thanks c041v! You lost me in the quote above, can you elaborate on how you get to the 15' estimate?�

Jan 8, 2015

JRP3 The overlap sequence may not matter with a flat roof the way it does with a pitched roof. I assume the flat roof will get some sort of water proof covering.�

Jan 8, 2015

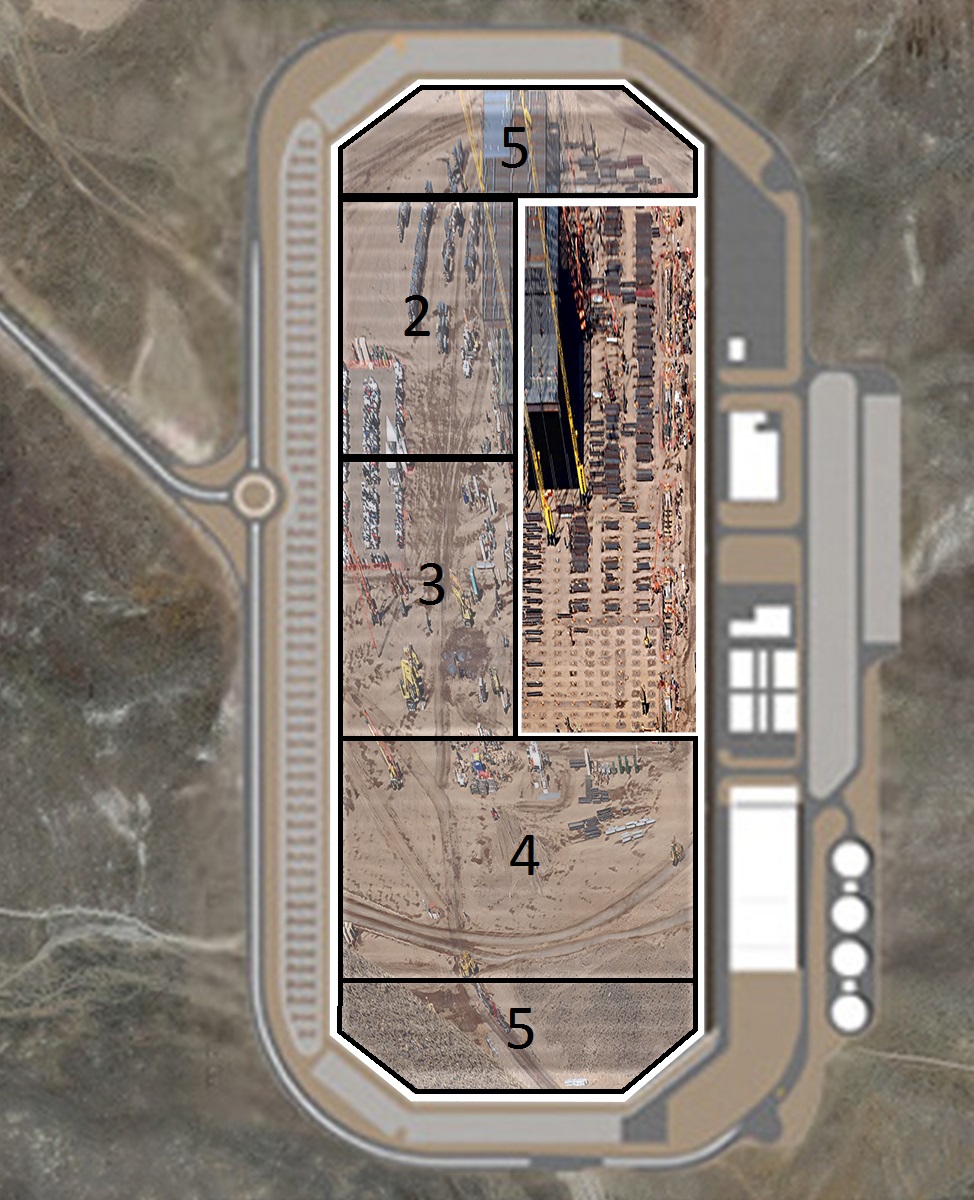

ajax

The scale, position, and perspective of the Gigafactory image I overlayed in Google Earth is pretty crude, but I promise it's aligned true north along with diapers.com and Toys R Us :smile: Here's an aerial view:

�

�

Jan 8, 2015

ScepticMatt Let me join in on the napkin math fun..

solar panels are 2:1 and there is a 42x8 grid.

So with white separators that works out to a 3:1 length to width ratio.

5 mln square feet ~= 450,000 square meter

ab ~= 450,000 => 3a^2 ~= 450,000 => a^2 ~= 150,000

so

width ~= 387m

length ~= 1,162 m

I've market the lengths in google maps and overlayed the gigafactory.

Edit: I see ajax beat me to it lol.

Edit 2:

Then I'd agree if you stretch your structure and foundation by a factor of two in the north-south direction

I.e down to the second white divider.

*fistbump*�

Jan 8, 2015

GenIIIBuyer Agree with this with the exception that the orange foundation part should be extended downward to the first white line.�

Jan 8, 2015

techmaven I agree... and the current structure is not up against the corner of the orange either, it's a bit further south.�

Jan 8, 2015

GenIIIBuyer Agreed techmaven!

Admins, maybe we could have wiki-post that tracks the current status of the Gigafactory? Could be updated based on pictures posted to forum, in similar fashion that Model S/X tallies were updated based on reservation numbers posted to the forums?

I envision coloring in the map above updated based on progress. I.e. Color X = Ground Flattened, Color Y = Foundation work underway, Color Z = Structure being erected. Color A = External Structure complete, etc...�

Jan 8, 2015

surfside maybe i'm missing something, but based on your picture it looks like the factory is going on top of an existing road -- is that right? anybody know where that road leads / what will need to happen with it?

surfside�

Jan 8, 2015

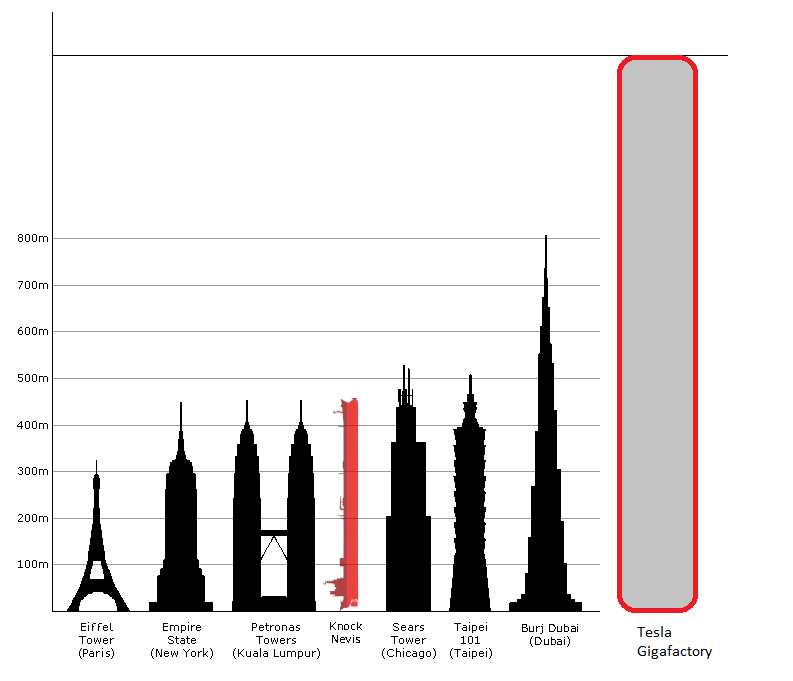

mrdoubleb It's safe to say the sheer size of this thing is staggering. Once fully built out, there will be a huge "wow factor" to it - once again, free marketing, media coverage.

So how big will it be? If Matt's numbers are right and it�s reall almost 400m wide and 1.2km long, consider this:

Note: original comparison charts shamelessly plundered from the internet. Gigafactory width not up to scale - was focusing on length.�

Jan 8, 2015

GenIIIBuyer Agreed, I think there is potential for it to become a tourist attraction. Maybe even a 3.5K run/walk fundraiser around it?!�

Jan 8, 2015

ScepticMatt That road is "Electric Avenue" (previously called portofino drive).

It ends shortly later at USA parkway, the new highway under construction and is only asphalted up to the Tesla site.

The same goes for USA parkway after the intersection with electric avenue

http://www.tahoereno.com/wp-content/uploads/2014/11/Overall_TRIC_siteplanTESLA1.jpg

Google Maps�

Jan 8, 2015

chickensevil To add if you look at the rendering provided by Tesla you can see that the old road is going to be diverted around the factory at that point. The traffic circle is where the intersection starts and they will move the road around the factory exiting on the bottom.

Pretty much, when you throw 5BN dollars at a state economy you get to move mountains and roads to suit your needs/wants (and even get to rename roads)

�

Jan 9, 2015

ajax

You're right. I was confusing myself trying to use c041v's 500' X 271' scaling for the current foundation. It's actually closer to 500' X 1100'. Here's the updated image:

�

�

Jan 9, 2015

ScepticMatt 21 new images from reno reddit user:

Tesla Gigafactory construction update (21 photos) : teslamotors

Tesla Gigafactory 1/7/15 - Imgur

Edit: scratch that only the single floor part is new, if you look at the parking lot.

Edit2: seems like the images are originally from reno gazette journal (in higher res there):

Tesla gigafactory takes shape in the desert

�

�

Jan 9, 2015

flankspeed8 Can I tell you how much I love technology? To be able to sit here in the frozen mid-west and watch this massive building literally sprout up from nothing and know the benefits it will bring makes me that much more anxious to get my hand on a Tesla! Is this not the most expensive building ever built for private business? What other factory will even compare? Perhaps some of the Boeing sites? Amazing....�

Jan 9, 2015

ajax

Well, my previous estimates were way off. Using a truck in one of the new pictures for scale, I think the section they're working on right now is about 570' X 2040' or close to 1/4 of the entire building. I don't see foundation on the far northern part yet, but that looks like an extra 160'. The whole thing would be about 1140' X 4400' or 10,032,000 sqft on 2 levels, not taking into account the cut out corners.

�

�

Jan 10, 2015

Vexar I would address this with the expectation that there's no need to bathe the entire floor in sunlight, and that a robot will work much more efficiently with a constant, targeted light source, such as a lamp on the end of an actuator. This would be akin to a human having a helmet with lights on it. Having been in the Fremont factory before the Model S was released, they are used to running factories with dark segments. Sure, there are some security lights, but it is on the order of illumination suitable for a parking lot at night. You can easily get >1000 lumens out of 10 watts in an LED light. A single square foot of an average solar panel is going to yield about 10 watts. Full sun is 10,000 lumens per square foot. Just inside a vertical window, you'll get as much as 1000 lumens. Let's go with illumination averages of 500 lumens in the factory. 750 is for your very bright stores, like Target (which uses reflective floors to help with illumination). If you string lights at 10 feet off the ground, you will have 1 / 10^2 or one one hundredth of the illumination, so that 10 watt LED @ 1000 lumens is going to illuminate the floor with just 10 lumens, 10 feet off the floor. However, that light spreads out. If you have one light per square foot and an even grid of lights in a 10x10 foot room, then at the center, you will have the centermost square foot receiving the most light, and the four corners of the 10x10 room receiving the least, because each light is contributing to the illumination of every square foot on the floor. The corners on the floor are about 20 feet from the centermost light, and the middle edges are about 14.5 feet from the centermost light. That means the center of the room is going to receive light from all 100 lights, starting with 10 lumens from the center, to 4 lumens on the edges and 2 lumens from the corners. If you assume an infinitely large room (which counts as the Gigafactory), then you can simplify the model to a diamond of illumination in our 10x10 square room will have a minimum of 4 lumens per LED on the edge and 10 in the center, for an average of 7 lumens per LED per square, for a 10x10 field of LEDs, or 700 lumens per square foot on the floor.

Consider how much dimmer the room would be if they were at 20 feet or 30 feet up. Placing the lights up at 30 feet, it would be about 75 lumens per square foot.

Now, I should probably point out that stores like Target have glossy, white clean floors and white ceilings for a very important reason: they reflect light. All the estimates above assume the room is built with matte black floors and walls that consume all light, like a space anomaly. In a perfectly reflecting room, it won't matter what height the lights are set. In fact, in a perfectly reflecting, sealed room, every square on the floor will receive 1000 lumens per bulb, and the 10x10 room will mean each floor will be illuminated with 100,000 lumens. If the room is only 1% reflective uniformly (which is a terrible oversimplification), then subtracting the 700 lumens, that leaves 99,300 ambient/reflected lumens reflected at one percent, which is 993 lumens! That means the room is now illuminated with 1693 lumens which is over 3x our goal of 500 lumens per square foot.

A two-story building could easily support a fully and brightly illuminated workspace if lit by LEDs and designed to have at least a 1% reflectivity in the workspace, consuming only 2/3 of the electricity generated by solar, when compared to simply having a bunch of skylights. It would also be a constant illumination, which is easier on human eyes. Now, this would only be effective for sunlight hours, which is pretty decent in Reno, but understanding the are a battery factory, they could easily store the surplus power generated for the off-peak hours.

Higher efficiency photovoltaic cells, better reflective surfaces, and adjusting light levels between work areas, movement areas, and storage areas means a two-story factory will have ample electricity produced to light itself via solar for longer than daylight work hours.�

Jan 11, 2015

AudubonB You guys with your ability to throw up pictures of ships, towers, etc. for comparison....

...perhaps some of you could have fun with other building footprints against the gigafactory dimensions. Pentagon, Boeing's Everett plant, the Alkmaar flower auction and so forth - those would be great to see.�

Jan 11, 2015

chickensevil The Pentagon is impressive because it has 7 floors. So yes the footprint is pretty big, but the sq ft of the building has 7 floors the play with.�

Jan 11, 2015

ajax

Well, if my numbers are right...

�

�

Jan 11, 2015

jhm Lithium plant to bring 400 jobs to Imperial Valley

It's exciting to see potential Gigafactory suppliers jump into the game. In this case, Simbol is a lithium producer looking to build a factory in California's Imperial Valley.

It does annoy me, however, that the Irrigation district may build a natural gas power plant to power this factory. If they really want to impress Tesla, they need to go with solar. This is in the middle of a desert, for crying out loud. It wouldn't hurt to give SolarCity a call.�

Jan 12, 2015

Robert.Boston The Pentagon has 6.6 million square feet of floor space, compared to the planned 10 million at the GF. I'll leave the graphics to someone more talented in that area.�

Jan 12, 2015

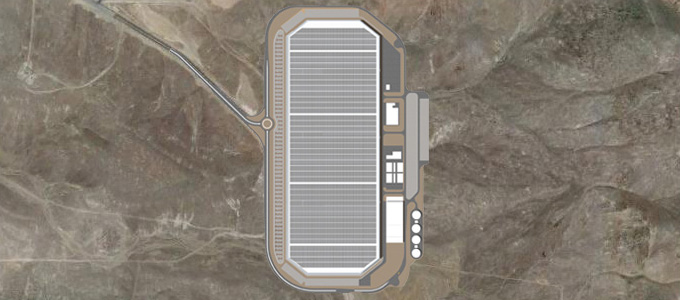

chickensevil Found this picture perusing the new Tesla Site on this page: Contact | Tesla Motors

I think this would be a better one to use to get a size reference with the surrounding area since it was rendered from top down as opposed to doing a perspective shift on the angled shot.

- - - Updated - - -

and just for kicks here is my very crude use of MS Paint to fit it into the larger Google Earth view.

This is slightly a bit bigger it seems from the other image that was perspective shifted, at least wider... but maybe not taller.�

Jan 12, 2015

Rheazombi love it! That definitely helps my brain visualize it.�

Jan 12, 2015

ScepticMatt Thanks chickensevil!

Funny that the gigafactory is now marked in google maps. Maybe they read this thread (hello?)

I made a better version. This also allowed me to measure it with google measure tool: 1175x425m

Accuracy depends on who made the tesla image. My previous guss using solar panels was 1162x387m

�

�

Jan 12, 2015

AudubonB Those numbers, Matt: 1175 x 425m, if a rectangle, is equivalent to 123 acres.

Dayumm! That's bigger even than my bathtub!�

Jan 12, 2015

LargeHamCollider Not sure if this has been mentioned yet but this will very likely be the second biggest building on earth, second only to Boeing's Everett plant. If the gigafactory's combined ceiling height is greater than 94.4 feet it will be the biggest building on earth by volume.

Some supporting math:

5,000,000ft^2 * 65ft = 325,000,000ft^3 this uses the estimated 40ft ceiling height of the first floor and the estimated 25ft ceiling for the second floor. Good for 2nd biggest building on the planet.

5,000,000ft^2 * 94.4ft = 472,000,000ft^3 this would be equal in size to the Boeing factory

- - - Updated - - -

List of largest buildings: http://en.m.wikipedia.org/wiki/List_of_largest_buildings_in_the_world�

Jan 12, 2015

chickensevil Yeah I thought that would be a good score since it gives us an official rendering that is set top down for proper scaling and sizing. Which I believe gives us the first REAL fit on the landscape.

Now we just need to attempt once more to sort where the current footprint fits in with the rendering which will tell us how many modules they will be building to make a complete factory. I am still thinking that based on their timelines given previously of their 5 phase approach I still think we are going to see 5 modules.

As a second option, maybe it will be four core modules and then the final phase is shaping it into a diamond (since that is missing from the current foundation) and also getting a proper roof on.

Thoughts?�

Jan 13, 2015

ajax Well, I've certainly been wrong before, but I think I'm getting closer :smile:. Assuming a beam spacing of 40' X 60' (I used pickup trucks and 20 ft shipping containers in some of the pictures for scale), then they're currently working on just over 1/4 of the total footprint. Getting the shipping/receiving section up and running from the beginning probably means a bigger first module. I'm guessing it's close to 2080' X 690'.

�

�

Jan 13, 2015

chickensevil Maybe it will be in an order similar to this:

Where the current footprint is the first section, and then they move over and sections 2 and 3 are a bit smaller. 4 finishes off the end. Then they add the diamond edges on last? Would still hit the 5 phase approach while accounting for the currently built foundation and taking your sizing into account.

- - - Updated - - -

I suppose we'll find out soon enough, how they really plan to do it. But I think your sizing helps give proper perspective of their progress given the footprint they are supposed to end up with in the end.�

Jan 13, 2015

Cattledog Excellent overlay Ajax, thanks. Exciting!�

Jan 13, 2015

ScepticMatt real-life size comparison:

�

�

Jan 13, 2015

Trev Page You forgot the banana...�

Jan 13, 2015

ScepticMatt I saw that, but it would be ~1/10th of a pixel even at that size...�

Jan 13, 2015

chickensevil Then clearly you need to scale your picture size up until a banana = 1 pixel �

�

Jan 16, 2015

ScepticMatt A list of Gigafactory work being done, along with contractors, phases and valuation:

Total ~$33 Million.

Source: Building Permits at Gigafactory Electric Avenue, McCarran, NV

Forbes Article: Tesla Gigafactory Permits Reveal Huge Costs: $16 Million For The Foundation Alone - Forbes

(via reddit)�

Jan 16, 2015

flankspeed8 Another development adjacent to the GF:

Switch to build huge data center near Tesla battery factory Tech News and Analysis�

Jan 16, 2015

dhanson865 Phase 1 is already completed? Phase 2 may or may not be completed, but the foundation and phase 3 work are in progress.

The only obvious phase 2 item was temporary power so either phase 2 was only power or phase 2 hasn't started yet and only the temp power for phase 2 has been done.

Retention basin should have just completed. Estimated work commencement date: 07/14/2014. estimated work completion date: 01/14/2015.

Foundation. estimated work commencement date: 10/27/14. estimated work completion date: 04/27/15. I'm not sure if the foundation is considered a phase 1 project, a phase 2 project or if it crosses the boundaries and exists as a project in multiple phases?

Phase 3 temporary power. estimated work completion date: 06/03/2015. I guess you could say this is phase 3 work or it's the last item in phase 2 that allows phase 3 to start?

all in all the items are interesting but I'm not sure what each phase covers (is the phase a concept of preparation, a designation of area worked, or a combination of those?)�

Jan 16, 2015

pmadflyer Hey guys, I made a massive image from the previously linked imgur images. I'll cut to the point. The 12th, 21st, and 31st column lines from the left are actually two column lines spaced ~3' apart with 1 to 1.5 feet gap between the floor framing. The 42nd line has similar larger foundations. The last row of foundations is number 53. In other words, we're looking at 5 independent structures.�

Jan 16, 2015

pmadflyer Here is a graphical representation of what I can see from all of the available images. I haven't posted an image yet, so I apologize if the size is too small or something.

�

�

Jan 16, 2015

jhm Gigafactory archetype

�

�

Jan 17, 2015

Cattledog Almost certainly building expansion joints.�

Jan 21, 2015

LargeHamCollider Trip Chowdhry says Gigafactory to be worth $50b: http://www.streetinsider.com/Analyst+Comments/Teslas+(TSLA)+GigaFactory+May+Be+Worth+Double+the+Current+Market+Cap+-+Analyst/10177487.html

For this to be true, at a production of 35Gwh/year and an assumed (somewhat generously) discount rate of 7% we would need Tesla to make $100/KWh if we model the value as a perpetuity...

I'm confidently long TSLA but I think more realistic numbers would be ~$50/KWh and a ~9% discount rate which puts the value of the gigafactory at about $20b.

One could include the extra 15GWh from shipped in cells but I'm not sure how this would be done, would probably only increase the value of the factory 7.5-15% imo.�

Jan 21, 2015

hobbes GigaLeaks

A leaked video gives a good impression of he GigaFactories Size from close up (from our non-investor sister thread):

Tesla-Gigafactory#185�

Jan 21, 2015

Robert.Boston Lousy video quality, but worth watching just to get a sense of the scale. It just keeps on going, and going, and going....�

Jan 21, 2015

eepic Seriously, eh? And thats only the pilot section... wow.�

Feb 4, 2015

Benz Nice article by Randy Carlson

"Tesla: Importance Of The GigaFactory"

Link: http://seekingalpha.com/article/2880476-tesla-importance-of-the-gigafactory?auth_param=79mcp:1ad5ak6:1904be49aa1dea0c4feca0d2051cc934&uprof=44�

Feb 4, 2015

32no Doh! You beat me to it. The article did an excellent job knocking the bear thesis off its feet, and it had a well researched analogy to Ford, as well as good insight into the Gigafactory. I think this belongs in the Long Term Thread as well.

Its refreshing to see such a good article among all the BS from both Bulls and Bears on SA.�

Feb 5, 2015

ggies07 Thanks for the link. I'm getting extremely tired of having to sign up or log in to read articles. Can someone post it here?�

Feb 5, 2015

chickensevil Summary

- Tesla's high share price is justified on the basis of rapid, long-term successful growth of their car business.

- Growth of the scale Tesla plans with their Gigafactory is rare, but an interesting and relevant historic parallel does exist.

- Recent pictures of the Gigafactory show the tremendous scale of this project and that it is progressing rapidly.

- Information in Tesla's most recent 10-Q filing gives some insight and Model X news may give more insight into critical Gigafactory progress.

Tesla Motors (NASDAQ:TSLA) is still a tiny, start-up car company, even though they are selling several billion dollars worth of cars on three continents. Investors are rightly concerned about Tesla's further growth because the stock price, even after falling back substantially from levels seen last summer, embodies high expectations that Tesla will become much larger and sell many more cars in the relatively near future. We need to understand if Tesla is on track to meet their growth targets and a look at Tesla's new battery plantbeing built in Nevada may offer some useful insight. This battery plant will be so large that Tesla modestly refers to it as their "Gigafactory."

First off, a little bit of historical perspective on Tesla's growth is in order. Tesla plans to make 500,000 cars in 2020, five years from now. Last year Tesla made perhaps 33,000 cars. We will find out exactly how many when they report earnings later this month. Not only is Tesla telling us they will grow their production by 15 times, they also claim they will reduce the price of their electric cars by half - all within the next five years. To reduce costs, and to obtain massive quantities of batteries, Tesla is building a very large Nevada battery factory.

While growth rates in automobile manufacturing such as Tesla is planning are unheard of today, just over a century ago, Henry Ford achieved almost precisely what Tesla seeks to achieve today. In 1911, Ford built 34,858 Model T automobiles. Five years later, in 1916, Model T production was 501,462 units. The price of the Model T roadster was $680 in 1911. By 1915 the price had dropped by 43%, to $390, owing to the economy of scale and vertical integration of Ford's manufacturing process. Ford's growth in Model T production, sales and manufacturing integration is a nearly exact parallel to what Tesla plans to achieve in the next five years.

Ford helped change a world of personal transportation powered by hay and oats into one powered by oil. Tesla is changing personal transportation from gasoline and diesel power to electricity. Vanadium steel was critical to Ford's success because it enabled their Model T to be lighter, more durable and ultimately cheap enough for most people to afford. To secure a large, stable supply of vanadium steel, at low cost, Ford built their own steel plant, theRouge.

Tesla is depending on advanced, lithium-ion batteries with high energy and power density, in huge quantities to enable high performance, long range and affordable electric cars. Tesla is building their own battery factory to obtain the quantity and quality of the batteries they need, at low cost.

Tesla's 1,000 acre battery factory site, east of Reno, Nevada, is almost exactly the size of Ford's Rouge complex. Tesla will even generate its own electric power on site - just as Ford did at the Rouge, but with wind and solar, instead of coal.

If this comparison of Tesla's growth to Ford's Model T experience does not fully convey the scale of Tesla's plans and battery plant undertaking, perhaps the following picture will.

(click to enlarge)

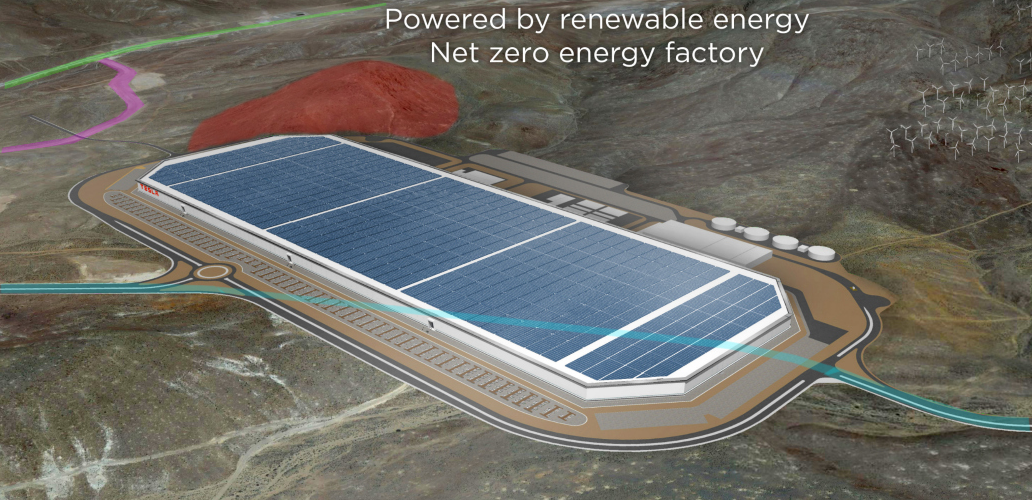

Portion of Tesla's Nevada battery factory under construction with heavy construction equipment in foreground for scale. Photo by author.

Tesla initially planned to construct the first part of their factory building this year, install and bring-up battery production equipment next year and begin producing batteries in 2017, in time for initial Model 3 deliveries. It is critical for Tesla to meet this schedule if they are to achieve their growth targets. Investors need to stay on top of Tesla's progress in Nevada if they hope to keep up with the market in Tesla shares. While specific data from Tesla on their progress in Nevada is hard to come by, this photo taken 31 January 2015 may be useful.

(click to enlarge)

Tesla's Nevada battery factory with estimated finished envelope based on currently complete foundation work. This first module of the factory is roughly 1,000 Ft. by 250 Ft., with 500,000 square feet of floor space on two levels. Construction appears to be on or even ahead of schedule. Photo by author.

Tesla has said they will begin battery production in a partially completed Gigafactory and expand production in more building space as it is finished. Tremendous as the Gigafactory building appears, it represents only one twentieth of the planned 10 million square foot Gigafactory. To complete the Gigafactory and achieve full-rate battery production by 2020, the current rate of construction will need to continue, unabated for the next five years. The pad area already prepared is many times larger than the building and "dirt work" on the site continues as can be seen from the large amount of earth moving equipment visible in the first photo. These photos here were taken on Super Bowl Weekend which probably explains the lack of activity - Nevada culture does respect certain priorities.

Tesla's recent 10-Q filing offers news on their progress in Nevada and some tantalizing information.

... Construction continued during the third quarter of 2014 at an accelerated pace with first cells expected to be produced in 2016 for use in Model S and Model X.The statement that construction has accelerated is consistent with the well advanced state of the Gigafactory building. The tantalizing part is the statement that batteries from the Gigafactory will arrive in 2016 instead of 2017, and that these batteries will be used in Model S and Model X. Tesla has said the battery cells made at the Gigafactory will be both physically larger and include some improvements to the battery chemistry. JB Straubel, Tesla CTO, mentioned this in his Silicon Valley/SEEDZ Energy Storage Symposiumkeynote last May. Because the new cells will be a different size, the pack design will necessarily differ from that used with the current 18650 form factor cells.

We plan to use the battery packs manufactured at the Gigafactory for our vehicles, initially for Model S and Model X, and later for our Model 3 vehicle, and stationary storage applications.

?

The speed with which Tesla is pursuing their new battery factory suggests that they will install manufacturing equipment for the new-design cells as soon as the building is adequately finished. This in turn will require that the decision to build this manufacturing machinery must be made later this year. Finally, if the production decision for manufacturing equipment is to be made this year, presumably prototype machinery will be running and doing at least pilot level cell production prior to the decision to commit to volume manufacturing of manufacturing line equipment.

All of this suggests that a limited, but likely significant supply of the new, larger cells will become available to Tesla later this year, and that means we could see the Model X roll out using the new cell design. If the new cells do include chemistry improvements, and higher specific energy, we may see a Model X with greater range than the current Model S, even though Model X will be a larger, heavier, higher drag vehicle.

Gigafactory progress is critical to Tesla's growth, and the status of the new cell is intertwined with the Gigafactory, and possibly with Model X. Investors should pay attention to news about Model X that relates to possible use of the new cell in this vehicle expected to begin production this summer. If Model X is seen to be using the new cell, this will indicate pilot production of the new cell has been achieved, that go ahead for the Gigafactory tooling can be given and Tesla's key supply of batteries needed to meet their growth goals is on track, or even ahead of plan.�

Feb 5, 2015

ggies07 Thanks Chickensevil!�

Feb 6, 2015

Robert.Boston reminds me of ...

�

Feb 6, 2015

Theshadows Thank you for the snippet. It's things like this that help me to stay super bullish when I'm in a slightly bullish mood.�

Feb 6, 2015

doggusfluffy From Reddit:

riffraff100214 10 points 4 hours ago

Here's a picture I took of the factory while flying out of Reno the other day. Pretty interesting to see how big it is compared to the other large buildings in the area.

http://i.imgur.com/D78Tvgh.jpg�

Feb 6, 2015

ecarfan In that photo is the gigafactory construction at the center right just below the cloud?�

Feb 6, 2015

jhm Nice shot. I love how much scale they're getting in just a few months of construction.�

Feb 6, 2015

Robert.Boston It's this thing, I believe:

�

�

Feb 8, 2015

Benz Interview of Simon Moores talking about the Gigafactory.

Link: http://kirillklip.blogspot.co.uk/2015/02/simon-moores-expect-supply-chain-focus.html#

Maybe someone would like to elaborate on his comments?�

Feb 8, 2015

ScepticMatt Musk also called the graphite environment issue story "beyond ridiculous"

Elon Musk on Twitter:�

Feb 8, 2015

JRP3 We never did get that environmental impact blog though...�

Feb 8, 2015

StapleGun Nice shot! I hope we continue to get aerial photos like these if that's a common flight route.

Randy Carlson's article mentioned that this current module is roughly 500,000 sq ft. or about 1/20th of the planned size. From that picture though it looks like the area cleared so far would only accommodate about 3 more modules of that size. Do we know which way the factory will eventually be expanding?�

Feb 8, 2015

vgrinshpun The interesting bits of information in this interview is that per the Simon Moore both LG and FoxCon are building "Mega" factories for the battery production. I guess using "mega" instead of "Giga" assumes 1000 times smaller scale (perhaps 50Mwh battery factory instead of 50Gwh battery??), but nevertheless is very good news. The scaling up and maturing of battery production will unlock a flow of resources into it's research, ultimately accelerating the path to a lower cost, higher energy density batteries.�

Feb 8, 2015

RobStark Boston Power is claiming it will have 8 gWh by 2018 from its Chinese factory.

Boston-Power Targets Own Gigafactory

LG Chem only says enough battery cells for 100k BEVs per year.

Koreas LG Chem Constructing Chinese EV Battery Plant�

Feb 8, 2015

aronth5 A few still shots taken up close on Feb 5th from the Reno Gazette

http://www.rgj.com/picture-gallery/news/2015/02/05/tesla-gigafactory/22948955/�

Feb 8, 2015

Fanatic This can't possibly be all the factory in that envelope.. The link under suggests that it would be over 3500ft long. That building is huge but not that much.

Tesla Gigafactory: Putting its size into perspective�

Feb 8, 2015

Fanatic If we look at this rendering tesla-gigafactory-nevada.png :we see the road leading up to the factory and the road leading away if we compare this to the flight pic you snapped, @doggusfluffy. One could think that it will cover almost all the pad created, the standing steel would just account for like 20% or less of the whole structure. THIS IS SO MASSIVE!�

Feb 8, 2015

vgrinshpun Interesting links.

According to the linked article the Boston-Power cell density currently stands at 200 Wh/kg. Given that cells used in Model S have 233Wh/kg, and assuming an average 7% per year improvement in density, as well as the fact that Model S is being manufactured since 2012, Panasonic cells designed to Tesla specs are about 5 years ahead of what Boston-Power is offering now (using the formula suggested by jhm). Not bad but Boston-Power needs to increase velocity of innovation for a chance to ever catch up:smile:�

Feb 8, 2015

dsm363 That's it.�

Feb 10, 2015

Benz TESLA TIMELINE: BUILDING A GIGAFACTORY (YEAR 1)

See at the bottom of this link: http://www.rgj.com/story/news/2015/02/09/tesla-summer-internships-unr-university-nevada-gigafactory-technobubble/22998527/�

Feb 10, 2015

JRP3 I think they are missing some zeros there, unless they are talking about a different building than what was pictured.�

Feb 10, 2015

chickensevil I think the 200k is just the cost of the shell. There were a bunch of contracts floating around and work permits that stated various costs. That might be where that number derives from.�

Feb 10, 2015

doggusfluffy Could they be talking about this? The battery systems building going up at the Tahoe Reno Industrial Center?

Tesla's ripple effect could touch everyone in Reno�

Feb 10, 2015

ecarfan Yes clearly that is what the article is referring to.�

Feb 11, 2015

JRP3  �

�

Feb 11, 2015

Krugerrand Clearly it's made of gold.�

Feb 11, 2015

ScepticMatt full image from the shareholder letter

... someone forgot to crop the image, lol

�

�

Feb 11, 2015

Rheazombi whose computer is that? They sure look Tesla obsessed. *stares at own revealingly Tesla-obsessed toolbar*�

Feb 11, 2015

Banahogg From the email name in the screenshot, I'm assuming it's https://www.linkedin.com/pub/kevin-kassekert/5/49b/473 - internal screenshot for the report that was over-included in the report.�

Feb 11, 2015

Fanatic would be fun to get that username and passwordnow i have to live of what the press gives me in terms of foto and video of the progress

�

Feb 12, 2015

Rheazombi everyone knows the secret password is MuskRulez1! :tongue:�

Feb 12, 2015

chickensevil We should start a petition to get them to either post a live feed or release updated time-lapse videos every week/month/whatever. I love time-lapse construction videos.

- - - Updated - - -

Oh, and I do love that photo is from the 5th and they put took the screenshot on the 10th! Waiting until the last minute are we? �

�

Feb 12, 2015

Robert.Boston Silly, that was last month's password. Now it's MuskRulez2 ;-)�

Feb 12, 2015

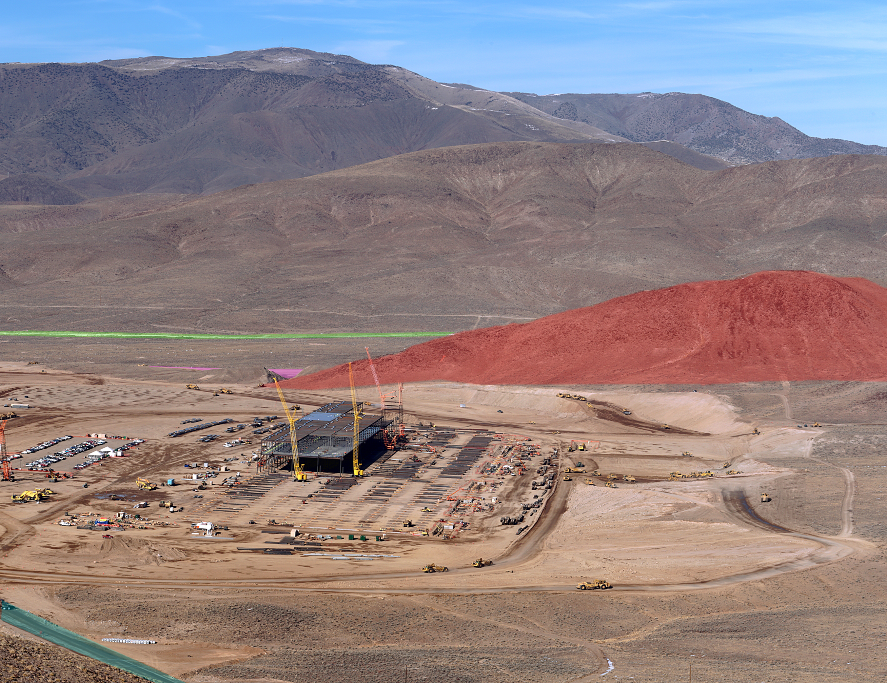

hobbes What is that building in the picture?! Gigafactory looks way different and

is not surrounded by paved roads. Is Tesla constructing two buildings there

or did the author pick the wrong picture?

EDIT: O.k., should have read the whole article first:

�

Feb 12, 2015

ecarfan I think that is correct. I see one road and a rail line. It is very early in the project. I don't know why you would expect to see more roads and structures completed at this point.�

Feb 12, 2015

Yggdrasill The Q4 shareholder latter said "We remain on plan to begin equipment installation later this year and for the start of battery pack production in 2016, in partnership with Panasonic."

How do you think this should be interpreted? One way to interpret it is that they will move the battery pack production from Fremont to the Gigafactory in 2016, but continue using imported cells for a while longer. Another way to interpret it is that they will make the battery pack from scratch at the Gigafactory in 2016.

I think it could easily make sense to start up pack production before starting up cell production. Pack production only requires moving equipment from Fremont, and there's a lot less hassle when it comes to clean-room requirements. Cell production should take a lot more time to get up and running. It needs a lot more equipment, and there's very little margin for error.�

Feb 13, 2015

hobbes Maybe I was not clear enough, I am not expecting more roads and structures, but the picture looks quite different from the pictures I have seen of the Gigafactory:

Official Gigafactory pic from ER:

This is obviously another project, as also stated in the article it comes from:

�

�

Feb 13, 2015

Model 3 That's my guess to... And one more reason for this: By moving the pack-production out of Fremont, the free some space there to prepare for the Model 3 production, something they need to have done at the time Panasonic delivers cells from the GF.�

Feb 13, 2015

RobStark http://www.sec.gov/Archives/edgar/data/1318605/000119312514403635/d812482d10q.htm

7 Nov 2014

Tesla 10-Q Securities and Exchange Commission report had the following information: (Page 26)

�

�

Feb 13, 2015

Yggdrasill It can still be interpreted several ways.

You might for instance see battery pack production start in Q1 2016, with cell production starting in Q4 2016. And since november, the expectation might have slipped from Q4 2016 to Q1 2017, for that matter. There will probably be a slow ramp-up of cell production, as they work out all the kinks, so for the first few months of cell production, most of the cell demand will probably still be met with imported cells.�

Feb 13, 2015

RobStark You can parse words ad infinitum.

Could would maybe possibly might

At earnings call yesterday Elon confirmed GF is on schedule and maybe slightly ahead.

Cell production starts in 2016. Whether Jan 1st 2016 or Dec 31 2016.

Moving cells from the port of Oakland to be packaged in Nevada to be sent back to Fremont makes little sense while you have no production in Nevada.

Fremont still has massive unused floor space.

Being opportunistic and buying properties at a good price in the Fremont area and moving in before absolutely necessary makes sense.�

Feb 13, 2015

jhm This seems pretty clear about cell production in 2016. It leads me to wonder why 30% of cells will be externally sourced at all. One hypothesis is that the cells produced at the GF will only be the lattest technology, highest density cell which will go primarily into automotive packs, and the outsourced cells will be used for stationary storage applications. To the extent that the equipment will be optimized for the latest technology cell, it would not make sense to invest in new machinery optimized for older technology. The text above is also clear that the cells made in 2016 will be for Models S and X, but late that packs may also be for stationary storage applications and may outsource cells. So this at least is consistent with my hypothesis.�

Feb 13, 2015

Model 3 Presumably because Panasonic would not have been with the GF plans without an assurance that their existing factories could still deliver cells. Reckon that in the long term either concludes this section (when there are more GF's up and running) or submit these cells directly into a Tesla factory in Asia (China?).

That's more or less their stated plan.�

Feb 13, 2015

RobStark Because in order to get Panasonic to invest ~$1B in the GF Tesla had to commit to buying Japanese cells made by Japanese workers in Japanese factories.

This is not a conspiracy theory but pretty much reported in the press and especially in the Japanese press.

Panasonic was not going to invest $1B in Nevada to remothball two recently reopened Japanese battery plants with recently recalled laid off Japanese workers.�

Feb 14, 2015

Trev Page There was a PDF that popped up some time late last year from the submitted permits to Reno for the GF and it showed the time scales for building and production. I saw cell production was slated to begin in July 2015. I'll have to see if I can dig them up or maybe someone still has a link to them??�

Feb 14, 2015

ScepticMatt This one? http://diversifynevada.com/documents/Tesla_Abatement_Application.PDF

construction timeline:

�

�

Feb 14, 2015

jhm Well, it's good to get some clarity on the intention for rhe 30% outsourcing. So if this is just to keep Panasonic plants in Japan working, there are other wasy to do this.

For example this new home grid storage device could be manufactued entirely in Japan. It really quite within Panasonics wheelhouse to make a finished electronic good. Have we heard anything about where these will be made?

Certainly as Tesla starts to make cars in Europe and Asia the Japanese supply could be directed there. But I kinds like the idea of building up astationary storage market to absorb capacity with slightly older technology. This sort of option improves capital effeciency. For example, if you have a brand new technology, build a new factory. Five years later, you've got a next generation technology. You could either upgrade your first factory or build a new one. If you've got a strong stationary market for the first factory, then you can make more off your initial investment by diverting its output to the stationary market and opening up a new factory with the latest tech. Five years later, you've got a new third generation tech. At this point the ten-year-old equipment in the first plant may well be due for replacement, so it makes sense to upgrade.

This does lead me to wonder what density of cell the home grid storage device will use. DemandLogic used 200 Wh/kg, but the Model S is using 250 Wh/kg. I wonder if the new device will use these higher density cells. Next up, the Model X gets say 300 Wh/kg cells. Perhaps the Model S won't get a range upgrade for many years simply because it would cost too much to upgrade 250 Wh/kg at this point in time. This could be why it is important both to build out the GF for 300 Wh/kg production while advancing a storage product to absorb the surplus 250 Wh/kg capacity. Once this surplus is absorbed or upgraded, then the Model S can get new batteries. So we can only hope the stationary market takes off as that will enable Tesla to advance the technology for cars at top speed.�

Feb 19, 2015

Fanatic Can't we hire someone to take a cpl of photos every day so we get a little progress reports. My search for new pics is dysfunctional.�

Feb 20, 2015

brandude87 Here's some new pics of the GF today from the local news in Nevada. Tesla Gigafactory Takes Shape in Storey County - KTVN Channel 2 - Reno Tahoe News Weather, Video -

�

�

Feb 24, 2015

eepic Here is some real estate agent's photos from Feb 15.

02.15.15 Tesla Gigafactory photos : teslamotors

A couple of recent developments that may be of interest here:

Samsung acquires Magna International's battery pack arm SDI News - Read News Articles | Samsung SDI

Alevo and Customized Energy Solutions partner to deliver 200 MWh of stationary storage to an ISO. It seems like they stick a bunch of batteries into a shipping container as a module that can be deployed, an interesting solution.

Alevo and Customized Energy Solutions Announce Largest Ever US Energy Storage Deployment - Alevo

Alevo and Customized Energy Solutions Announce Largest Ever US Energy Storage Deployment | Customized Energy Solutions | CES�

Mar 3, 2015

Benz Randy Carlson

Tesla: Gigafactory Tipping Point

Link: http://seekingalpha.com/article/2966026-tesla-gigafactory-tipping-point?app=1&auth_param=79mcp:1afcete:2b0fbf9f68a85cd10d3ac3a8e7d216b0&uprof=44�

Mar 3, 2015

30seconds Very interesting. I'm not aware of how he did his total vehicle weight calculations, but the overall point that Tesla in on a declining cost curve and ICE is not is a very important one�

Mar 3, 2015

Maknyuzz Instagram Instagram

Kimbal's instgram has some pics of GF progress�

Không có nhận xét nào:

Đăng nhận xét