Mar 29, 2015

FlasherZ If you've suspended the "remove the cells from the module" program, you may consider donating the module to your local fire department and letting them purposely create a fire with them for training purposes.�

Mar 29, 2015

oneday I doubt a local fire department has the ability to educate such a large international group of enquiring minds. The willingness of wk to share his experiences and knowledge is really about as philanthropic as science gets. We aren't getting the abridged edition, we are getting the moment by moment update. He is giving us the nitty gritty details just because he wants to, I think he can handle his project without giving cells to the fire department. obviously any fire department could benefit from the knowledge obtained from testing, but when was the last time you followed a fire department blog�

Mar 29, 2015

apacheguy Would some kind of solvent work?�

Mar 29, 2015

bxr140 Doubtful--anthing harsh enough to weaken the epoxy is going to have a laundry list of associated problems.

wk057--are the cells potted, or just bonded at the base? If they're potted, how is the negative connection made?�

Mar 29, 2015

wk057 I thought about a solvent then immediately rejected the idea since I have no idea what the insulator partitioning the positive and negative electrodes is made out of and how it would react to such a solvent.

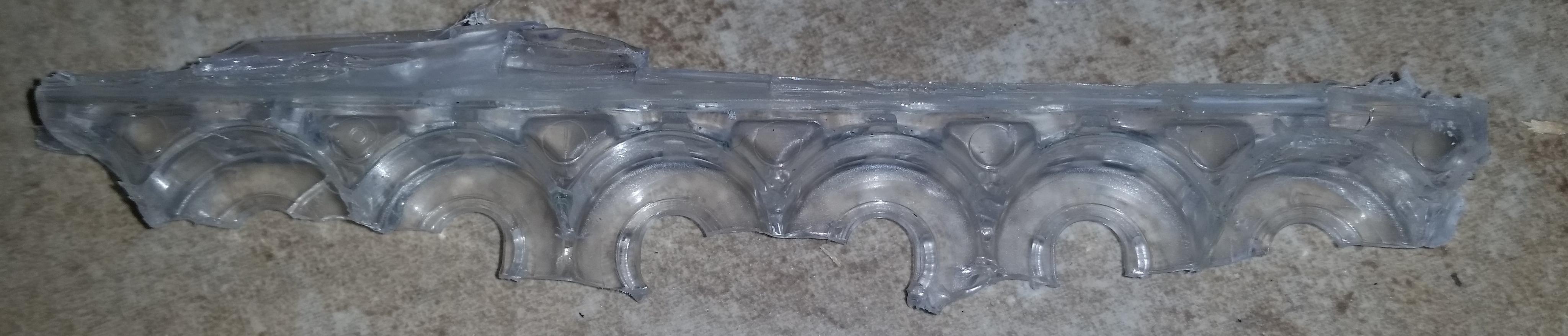

As for how the cells are held in place, here is a pic of a shard from the edge of the framework that holds them that didn't have much if any glue on it.

This is the inside side where the cells sit. The cells sit in their own little recessed spots with a cutout on the end for the cell level fuse connection. On most of the module the glue is all inside this recessed spot and excess around the edges on the inside part. Very little, if any, excess adhesive on the terminal side. But they're glued all around the casing in that ~1/4" recess.

- - - Updated - - -

As for donating some cells or the module to a fire department, probably not as useful as it would seem. I may contact the NFPA about it and see if they want to do some testing/experiments with it if I can't find anything else to do with it.�

Mar 29, 2015

okashira I will share how to remove the cells soon, someone just buy the rest of the 3000 or so I have on hand. �

�

Mar 29, 2015

FlasherZ I'm not the person to ask that question and expect the answer you're getting. I'm regularly speaking to various first responder communities on how to deal with these situations, especially local volunteer fire departments.

The point wasn't that he needs to give them to fire departments, but rather if he's given up on extracting cells and has a damaged module, he has an option to donate it to a local fire department that can do training (similar to how we use dilapidated homes for training exercises). Of course, if there are better uses, then he does have a right to put them to use. I was thinking they could create true runaway by purposely damaging some cells and applying flame-o-matic.�

Mar 29, 2015

mitch672 I work at BatteryMarch Park in Quincy, which is a complex of buildings where the NFPA's headquarters are located.

One day, the head of the NFPA's Head of the "Electric vehicle safety program" was waiting for me by my Model S, he wanted to use my car for a photo op at their onsite EVSE... since then, they've also shot some promotional video of my car driving around in the parking lot. At any rate, I can put you in contact with him, if you'd like to see if they have any interest in examining/testing the remains of your module. let me know, thanks.�

Mar 29, 2015

wk057 Definitely going to investigate possibly uses for the module. If there is something that can be gained from it via local training or otherwise, I'll look into it.

After having some time to mull on yesterday's event, I may try extracting more cells in a different way. But with even more precautions. Mainly, I want enough cells to run some meaningful tests of capacity at different discharge rates along with some cycle life tests as well as some to share with some others who would do similar testing to confirm.�

Mar 30, 2015

JRP3 Apologies if I missed it, but did you ever confirm a definitive total cell count of 7104 cells for the total pack? Also, have you done an actual capacity test of an individual cell?�

Mar 30, 2015

tga I live pretty close to the the Massachusetts Firefighting Academy: The Massachusetts Firefighting Academy (MFA)

If the NFPA doesn't pan out, I could try to head over there on a work from home day and see if they want them. Although I'm not sure how easy it would be to ship from NC to MA.

Edit: Now that I think about it, all states probably have a similar training program to the MFA - you could probably find NC's equivalent.�

Mar 30, 2015

kennybobby Put me on the list for capacity testing, i have an HP 6050A DC electronic load that can discharge up to 6 channels simultaneously. Would be happy to help.�

Mar 30, 2015

bluenation you were very very VERY lucky none of your loved ones were standing in the way of that stray batt.

that said

+1

you are doing it for science, wk. Thx a ton.�

Apr 9, 2015

wk057 I finally got around to doing some testing of the cell level fuses using a power supply and my DC electronic load.

I was able to get them to carry 24A for 60 seconds+ and they would consistently pop within a second or two at 25-25.5A.

Honestly, that's more power than I had figured they were able to handle. Assuming they're sized for 25A, that's 90W per cell, almost 40kW per module, or close to 8C max before consistent popping.

Using an NEC-style 25% margin gives me a constant current draw of about 19A possible before popping fuses. That'd be about 6C, or about 485kW nominal for an 85kWh pack.

This could explain the reason the P85D doesn't show 691 HP (515kW) under full acceleration. However, that's speculation since the D variants have a different battery pack part number which may or may not have larger fuses. No way to know for sure until someone tests the fuses in one. I believe the full 515kW+efficiency losses could be pulled from a fully charged pack for a very short burst, though.

Edit: It's worth noting that the primary goal of these fuses is likely simply to prevent a single cell with an internal issue from destroying the rest of the cells, not to protect against module max current draw. Let's say a single cell developed an internal short. The other 73 cells in that set would then be sending all of their power through that cell, since they're in parallel. With the fuses, the fuse would just pop under the hundreds of amps available, and barring any thermal issues related to the bad cell, would save the rest of the cells.�

Apr 9, 2015

apacheguy I think it's a fair assumption that some fundamentals have changed with E and F packs. They are able to sustain higher current draw for longer periods not just while flooring the accelerator, but also while supercharging. I suspect the individual cells have been upgraded as well.�

Apr 9, 2015

okashira Did you test the fuse while still attached to the bus bar?

Ie, one lead attached to the end you cut carefully from a cell

the other lead clipped to the bus bar

- - - Updated - - -

I don't agree with this assessment. In fact, my analysis of the P85D performance and charging shows almost no difference in charging, voltage drop, and only ~390kW peak draw from the pack, for only a very short period (at full charge) [~370kW at 70% charge]

That's only ~16A per cell for ~5 seconds, and it quickly tapers to half that, and even lower. This is easily sustainable by the existing cells.

If anything the only difference between a D and an E is the wiring for the front motor, perhaps upgraded connections.�

Apr 9, 2015

wk057 Basically. I left one end attached to the bus bar, and the other end I pulled from the cells to keep the length correct. A few I snipped. Didn't change the result for either method. I fed power into the bus bar and to a tight clip on the very end of the fuse with my electronic load setting the current.

I'm not sure I agree with either assessment.

The part description for the P85D pack is "ASY,HV BATTERY,S3,DUAL MTR,MDLS". The S3 I think is the important part. The modules themselves have the S3 label on them. I see no real indication that they are difference cells, although they likely have heavier internal wiring.

Also, as for power draw, at full throttle the P85D kW meter lands just below the 480kW mark. I'm not sure where the 390/370kW numbers come from...

There is no front motor wiring related to the pack itself. The wiring for the front motor comes from the rear seat area and is routed via the driver side to the front motor.

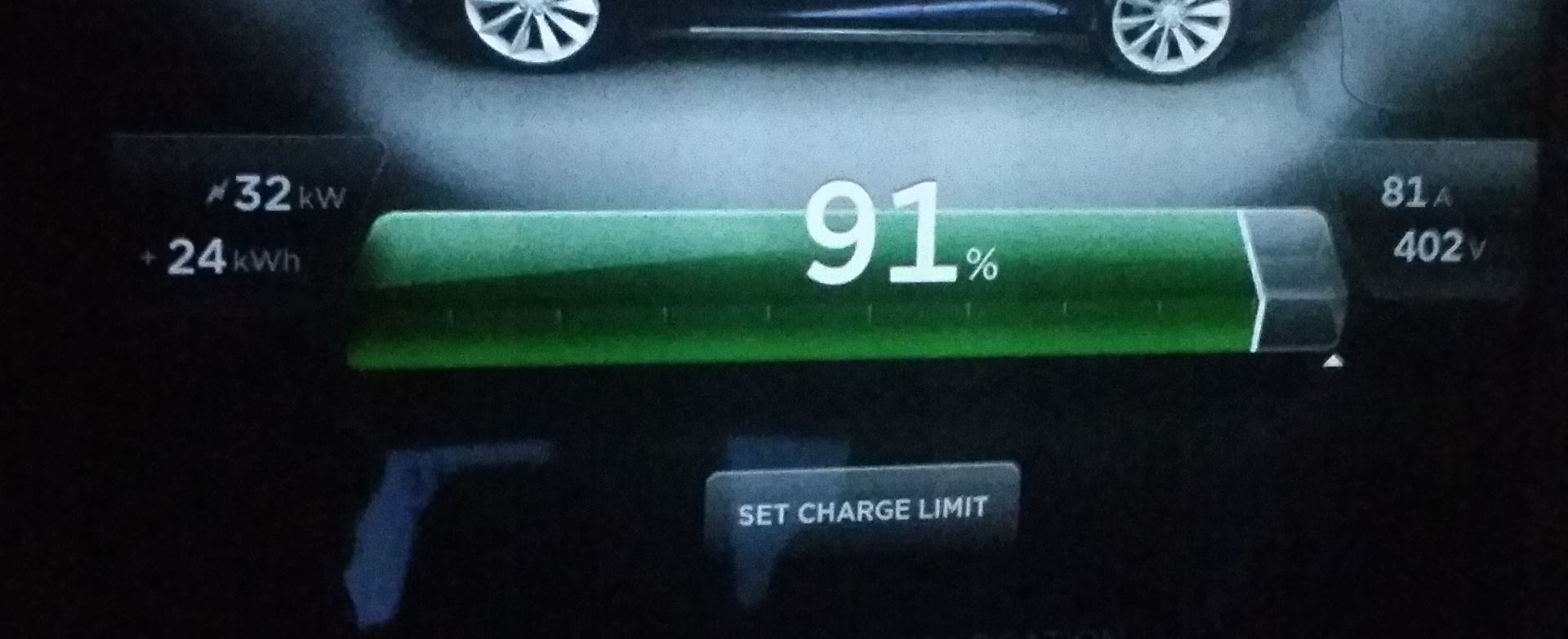

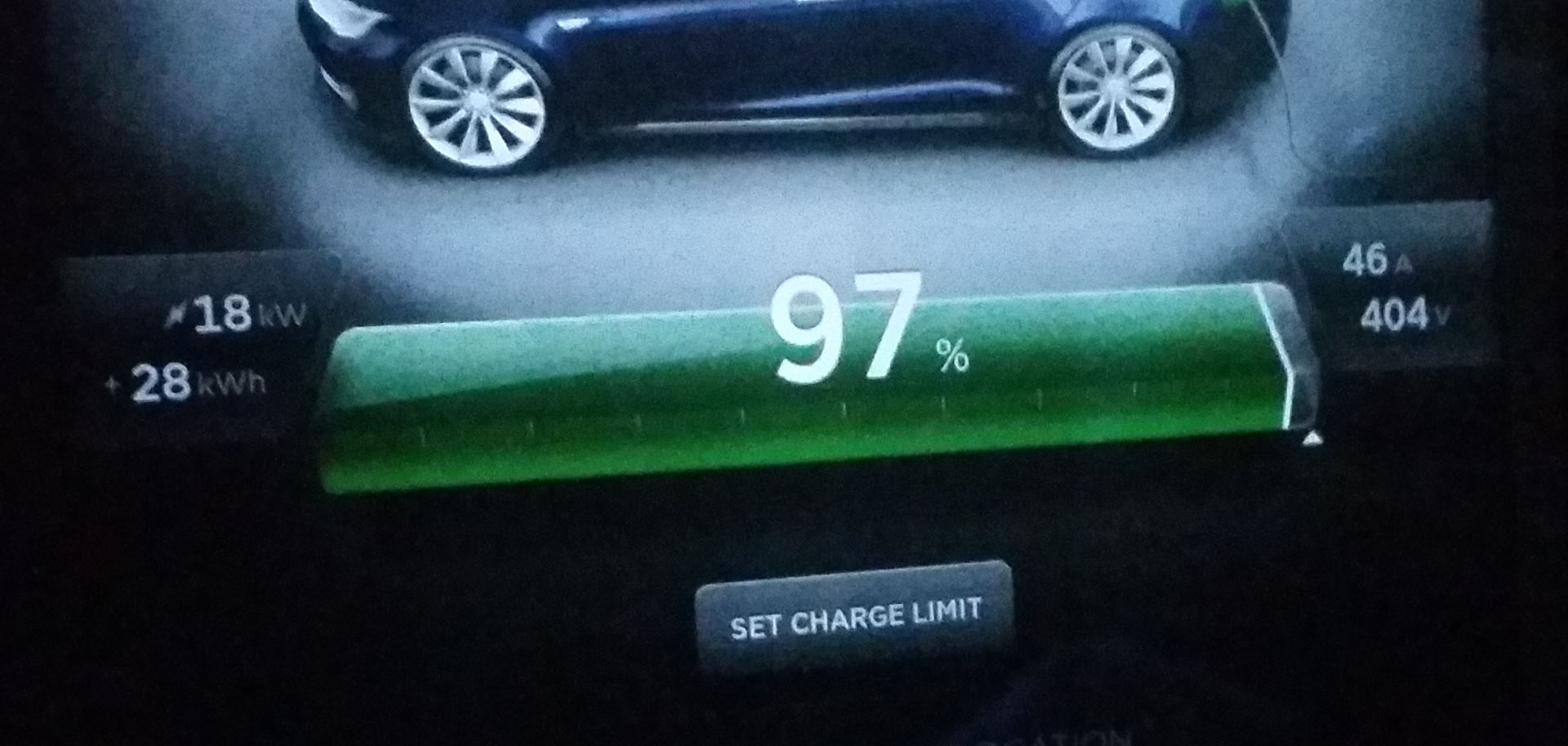

Edit: Maybe I'm crazy, but I can't find any pics showing these points on the taper for my P85 showing power at these levels during a supercharge at these SoC.

Edit: Actually, I found a fuzzy pic from my P85 showing 257 out of 264 rated miles, which would be ~97% showing only 6kW vs 18kW on the P85D. *shrugs*

Looking through my pics I seem to snap them to show the peak output and not the taper. Maybe I'll try to do a side by side next time I have both cars at a supercharger.�

Apr 9, 2015

Johan I'm amazed the fuses were so precise and consistent in their behavior.�

Apr 9, 2015

wk057 Yeah, me too. I popped about 30 of them in testing with consistent results.�

Apr 9, 2015

llavalle Not sure I'm following you here. Did I miss something about the tapers?

I just did a 15->90 SOC supercharge on my E Pack and I've got a video of it (sent it to okashira). What were you looking for?�

Apr 9, 2015

okashira "Just below 480kW" would be ~390kW.

Did you notice the scale is logarithmic? ;-)

Great way to hide the large power taper that's done, as well as make one think that "just under 480kW" is more then the actual ~390kW.

Endless-sphere.com View topic - Tesla P85D Insane Mode

The acceleration of the car also about right for a car with ~500bhp or slightly less.

The images you posted don't show anything. There is of course a huge difference in charge rate between 91% and 97%.

Not to mention you need to compare same firmware and same BMS.�

Apr 9, 2015

wk057 Specifically the taper seems a bit better (higher power longer) in the 90-100% range on the P85D. Below 90% it seems to be the same or similar.�

Apr 9, 2015

okashira Nothing missed, the images posted aren't comparing apples to apples.

Thanks for the vid, I will plot your charge curve vs a b pack by the weekend. Initially, it looks pretty close.

- - - Updated - - -

You need to compare 95% to 95%. And same firmware.

You posted 91% and 97%.�

Apr 9, 2015

wk057 The 91 and 97% were the same car (P85D) on the same charging event... I'm not stupid. lol. (But admittedly guess I didn't make that clear.)

The last one, 257/264 rated miles (97.3%) was the P85 I traded in December.

At no point have I had access to both the P85D and P85 on the exact same firmware. Even now the fiance's P85 has 2.4.136 and I have 2.4.124. They never seem to ever be the same, but I think this is a moot point anyway.�

Apr 9, 2015

okashira Agreed with that. There is lots of variance even with same firmware on a different day on a different charger. Comparisons are difficult that way. I can at least compare dV/dI at various SOC to see if the cells/pack has less DCIR, looks the same so far.�

Apr 9, 2015

apacheguy Really? You know that a single motor P85 is able to pull 370 kW peak power, right? Seems odd that the PD can't do more than that.

Care to share?�

Apr 9, 2015

llavalle Sure, here it is.

I re-processed it and removed audio.

Processing should be done soon.�

Apr 9, 2015

kennybobby What was the diameter of the fuse wires? And the material--copper, aluminum, silver...?�

Apr 9, 2015

apacheguy Huh, so it crossed the 100 kW threshold at 38% and the 90 kW at 44%. Better than mine, but not as great as others have reported. I seem to recall others recording > 100 kW at > 40%�

Apr 9, 2015

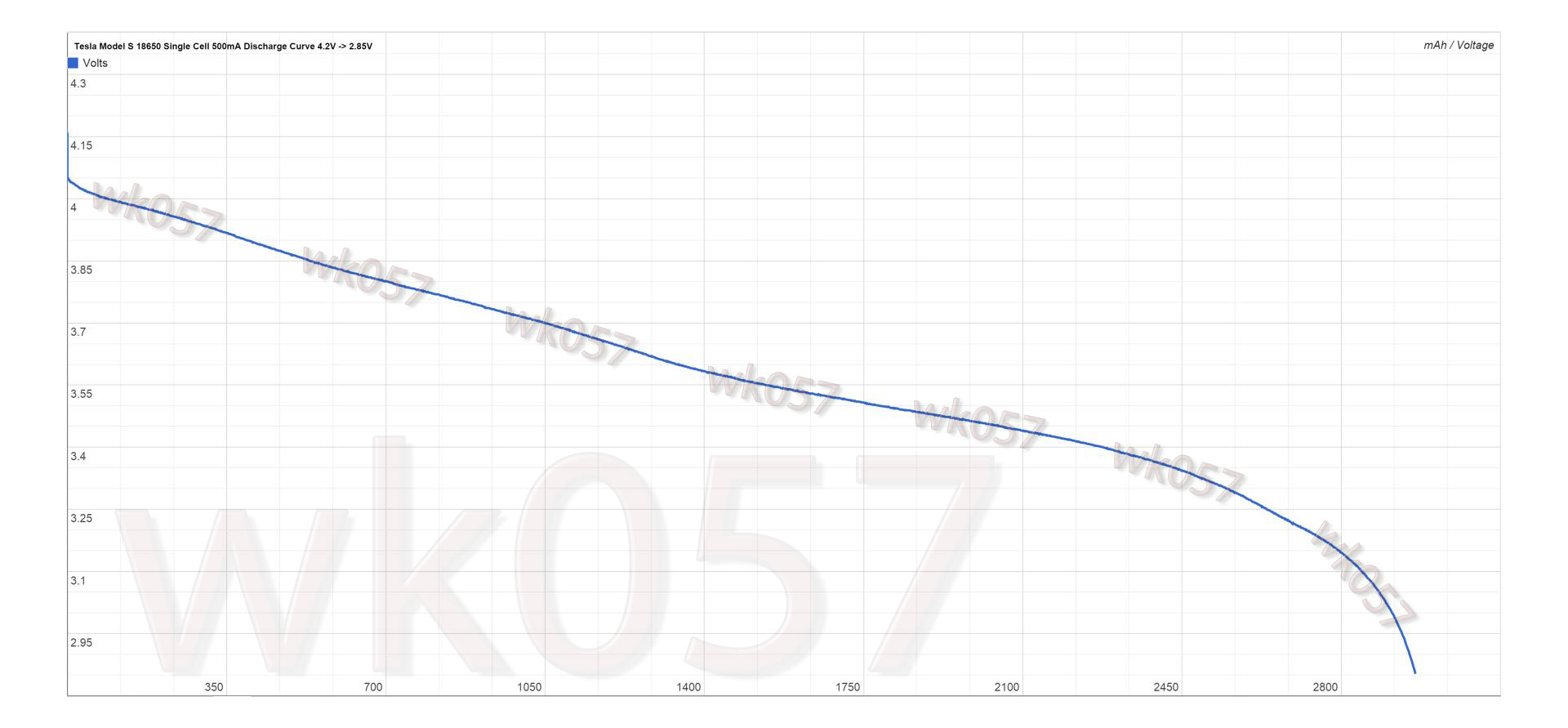

wk057 So, finished my first 500mA discharge curve for a single cell from a Model S module. Charged to 4.2V @ 1A constant-current, then constant-voltage until current dropped to 120mA, 5 minute delay, then discharge at 500mA until voltage read 2.85V. Test was done using FMA Powerlab 8 and the custom settings above. After charging the cell settled to a resting voltage of about 4.16V.

Was able to draw 2,963mAh. Using 10 second voltage averages this came out to 10.605 Wh. That'd be about 4.7kWh for a module, or about 75kWh for a full 85kWh pack using this method. I think there is room for improvement on the extreme ends, however.

My 120mA charge current during CV stage could probably be dropped to squeeze some more juice into the cell, and I could probably discharge it lower than 2.85V. There was ~100mV voltage sag at the begining of the discharge, also, and this seemed to increase quite a bit during the cycle as evident by a resting voltage of ~3.1V after removal of the 500mA load. I may try soldering heavier gauge wire to my 18650 cell holder later and retesting to see if that improves the voltage sag.

�

�

Apr 9, 2015

billarnett Is it possible that the cells you're testing may have been damaged before you got them?�

Apr 9, 2015

wk057 I think it is unlikely. These in particular are from a 85kWh D-pack with relatively low mileage (< 5000 miles) front end collision, and when I received them they had about 3.7V charge (probably 50-60% SoC). They aren't physically damaged.

It is likely is that my cheap cell holder and its wiring has too much resistance for an accurate measurement with minimal losses.

It's also likely that I didn't fully top off the cell, nor fully discharge it. Without knowing a spec for a safe lower limit for voltage, I'm not comfortable taking them too far below 3V. CV charge at 4.2V makes sense because this goes along with the Model S supercharging voltage readout during the CV phase 404V (4.208V per cell).

I'll try some more testing when I get more time to do so, for sure.�

Apr 10, 2015

WarpedOne So, these continuous discharge tests show that cells only hold about 3Ah, about 10% less than needed for a 85kWh total capacity.

One explanation may be that in a car cells see different "discharge profile" i.e. intermittent discharging with long time intervals of inactivity that allows them to 'recuperate'.

Can you set up a test where discharging happens in discrete intervals and measure voltage?

I'd guess average voltage (and hence also Wh rating) under such discharge profile will end up higher than under continuous load.

Remember that these cells are supposed to be optimized for automotive use. What exactly this means only tesla knows but for sure it is not constant discharge current.

If anything, constant discharge current is something these cells never see in a car.�

Apr 10, 2015

wk057 Well, an exactly constant discharge current... probably not.

However, I've personally driven the Model S continuously on the highway from 100% to 0% charge with an average discharge rate of about 21.6kW over 3.5 hours, according to the trip meter. That's an average draw of ~3.04W per cell, or ~850mA at nominal voltage, or about 1/4C using 85 kWh as the capacity.

My discharge test was at 500mA, which would be closer to a 12.7kW average draw for a full pack, much lighter load I'd guess.

The fact that both my test and the car's dash yield a number around 75kWh is definitely interesting, though.

If I get the time I can try to do a more car-like test, but probably won't be soon.

Suffice it to say, I'm very curious where the 85kWh number actually comes from now.�

Apr 10, 2015

Johan Me too!

As I posted in okashira's thread on his testing, where we all agreed that rating a battery in kWh has to do with the discharge profile i.e. under different types of load the same battery cell will perhaps have to be rated differently. So as I posted in that thread what does this really mean when rating an entire pack in kWh? If you have a battery pack that is for automotive use, like the Model S pack, and you could never, ever, under any circumstance that has to do with running a car, have the pack deliver more than say 81kWh then how can it be correct to rate it as an 85kWh pack? Okashira's reply, which is of course sensible, was "what does it matter, isn't it range that matters?". Well, of course range is what matters in the end, but since Tesla have started rating these pack in kWh it would be nice to know how they've actually come up with the number.

Also, with regards to for example the Gigafactory, Tesla might say "We've produced 10 GWh of batteries". Now, what does that mean? If the same number of cells go in to a battery used for home storage the use profile (discharge/charge rates, load etc.) may be different and thus in fact result in a different kWh rating for that pack, than were it to be used as a car battery.�

Apr 10, 2015

wk057 Well, 500mA is 1/6C is the cell is actually 3Ah. I'll try a super low discharge rate like 50mA or 100mA and see where things end up under that light load. Unfortunately such a test will take days and I'd prefer to be around while it's happening.�

Apr 10, 2015

WarpedOne Average discharge is not the same as constant discharge.

I beg you try discharging them at different loads, try to mimic discharge spikes and some 'cool-time' with 0 discharging.

If you could throw in some short charging moments we would start to see the real picture.

Crazy-thought: 85 kWh includes regen under 'normal' driving conditions.�

Apr 10, 2015

Matias That would be false advertising.

I sure hope Tesla's pack IS 85 kWh pack. Otherwise headlines will be killing.�

Apr 10, 2015

wk057 I may be able to just take a data log from back when I was logging drives with Tesla's API and use those power draw numbers, divided by 7104, to put the same usage/stress on a single cell using my DC electronic load for draw and bench power supply for "regen", and measure net output power.

I definitely first want to simply try engineering a better test setup for connecting to the cell safely and efficiently, though. I'm still wagering that a good portion of the disparity is in the actual test setup's connection to the cell causing greater than normal voltage drop during discharge. This would be evident in an extended super low current test I'd think, which should be much simpler to test.

Edit: The one cell actually just finished recharging, so I just threw a 100mA load on it just to see how the voltage drop looked, and it was only ~25mV vs the 100+mV drop at 500mA. Definitely points to needing a better connection to the cell for better tests.�

Apr 10, 2015

Johan I was reading up on the concept of nominal voltages and how batteries are rated for capacity.

(Source Battery University)

But what is being said in this tread then, if I'm understanding it correctly, is that if you integrate for power delivered ("area under the curve") while discharging a battery the area=total power delivered will vary depending on the slope/shape of the curve i.e. the use case (faster/slower discharge, average discharge rate, bursts etc.)?

If so, aren't Tesla just adhering to industry standards as they rate their big pack at 85kWh. In other words they just take the rating from Panasonic and multiply by however many cells are in the pack?�

Apr 10, 2015

WarpedOne Yes.

But industry standard is not to integrate but to cut shortcuts using 3,6V or 3,7V as a magic number.

Nope.

85.000Wh / 7104 cells = 11,965 Wh/cell

wk measured those cells a bit under 3000mAh. To reach 11,9Wh at 3Ah, the nominal voltage would need to be 3,99V. According to the picture above also this is clearly not so.

One could probably stretch those cells a bit higher and lower but I just cannot see how can you stretch them to reach 11,965 / 3,6 = 3300 mAh or even 11,965/3,7 = 3230 mAh�

Apr 10, 2015

JRP3 Worth considering is the steep initial capacity loss. A cell that tested 3.2ah at the factory at 100% might drop a percent or two after a few initial cycles.�

Apr 10, 2015

lolachampcar Slightly off topic but relevant to an earlier post and comments in other threads-

I am curious as to the source of all the angst for Tesla not providing an "accurate" spec. when something like battery capacity or motor horsepower is concerned. Are the nominal values of much if any importance? Is it not how the system performs in the wild that matters?

I really do not care if the battery is an 85 by one person's definition and a 75 by another nor do I care if the motor(s) are 500 hp or 800 hp. What matters to me is how far can I go in the car and how does the car perform. If I get 240 miles out of my PD on a trip leg and it gets to 60 mph in 3.3(ish) seconds then I believe Tesla has delivered. Any focus on numbers or specs to paint the company in one light or another seems simply to be politicking. Am I missing something here?�

Apr 10, 2015

WarpedOne A few percent yes but over 10? And then in the next few years only few percent more?

I find this hard to 'believe' without actually seeing the data that proves it.

My bet is still on intermittent loads that somehow get a bit more energy out of the cells.

There is a bit of "infant mortality" and I also bet a touch of marketing - tesla never said those battery is 85.000 Wh, they only said 85kWh.

It might be marketing that rounded those new 82,6kWh to the nearest multiple of 5.

Some people can drive it, others can only discuss it �

�

Apr 10, 2015

Johan I agree with this in general. Performance and range is all that really counts, in the end.

However, you will create a lot of confusion by letting the user see very detailed Wh/mile numbers in the car, yet when you do simple math the numbers don't add up. Remeber, it's Tesla who have designed the UI that show these detailed values.

Let's say I'm an averge Joe consumer. I got me an 85kWh car. I charged it to 100%. I'm driving at an average of 300 Wh/mile (the car tells me so). So I can go 85000/300=283,33 miles until I run out of charge, right? Or not? See the problem?�

Apr 10, 2015

JRP3 That would be counter to all known capacity rating tests.�

Apr 10, 2015

lolachampcar Johan,

I see your point. I actually faced that conundrum when I first started driving MS but then realized the numbers did not add up and moved to believing the range I had experienced. From that point on, I simply used the WHr/mile number as a gauge of my performance as a driver and to spot environmental issues that could affect range.�

Apr 10, 2015

scaesare I always wanna know how stuff works. Doesn't matter if it's a clock, an operating system, or a car.

- - - Updated - - -

I believe ~50ma might be more like the CV cut point on the top end.

I wonder what the low-discharge threshold is that Tesla uses. I thought I've seen some of the diagnostic screen voltages that implied it wasn't much below 3V (which would be right given a Vnom. of 3.6v).

Okashira's test went down to something like 2.5v....�

Apr 10, 2015

apacheguy Cant we calculate that from SpC sessions where the owner connects with rock bottom SOC?�

Apr 10, 2015

Johan I'm I just plain stupid?

2.87 Ah x 3.6 V nominal x 7104 cells = 73.4 kWh (kVAh)�

Apr 10, 2015

scaesare

I think there's some likelihood that although the cells may be rated to discharge down to something lower, and thus "really" have ~85KW of total capacity, Tesla conservatively operates in a shallower voltage envelope to provide greater battery cycle life, protection from bricking, etc...

- - - Updated - - -

Certainly should be able too... now to find some of those pics/videos...

?(And I'm now preparing to be annoyed that the forum will coalesce my posts)�

Apr 10, 2015

billarnett Did the cell get hot during the discharge? Perhaps Tesla's careful thermal management makes a difference to the total measured capacity?�

Apr 10, 2015

wk057 No noticeable change according to my FLIR�

Apr 10, 2015

austinEV This reminds me of harddrive "megabytes" that are 1,000,000 bytes instead of 1,048,576.�

Apr 10, 2015

Johan This is a good analogy for how this issue can be confusing to the consumers as I described above, and could tarnish Tesla's rep. in the future when people start realizing the math doesn't add up.

(I think this is an interesting discussion but that it is derailing wk's great thread, so I hope an administrator would "carve out" this discussion to a separate thread).�

Apr 10, 2015

AnxietyRanger Just wanted to extend my thanks again to wk057 and others paying detailed attention to this stuff. Magnificent contribution(s) and much appreciated.�

Apr 10, 2015

lolachampcar ++++�

Apr 10, 2015

redi Yep, they are pioneering and passing the info for all of our benefit - info that is unavailable elsewhere.

Thanks.�

Apr 11, 2015

Filb

A possible (although unlikely) explanation for the slightly lower capacity that you found was that maybe Tesla measured full pack capacity from the pack itself, or from one of the 74 in parallel blocks to calculate total pack capacity.

When batteries are wired in parallel, their internal capacity decreases (similar to the way resistors in parallel have a lower measured resistance). Since some of the energy in a battery is lost to heat because of internal resistance when being discharged, the significant drop in internal resistance from being paralleled may make up the difference in capacity that you measured.

Even though the 74 in parallel are then wired in series which increases internal resistance, the decrease in internal resistance from being paralleled is greater than the increase from being put in series.

This will make a difference to the measured capacity of the pack, especially at higher discharge rates.

However, from what I have read, I think that Tesla likely discharged the cell to a lower voltage - possibly 2.5 volts for capacity measurements and a better connection to the battery might give you a higher capacity measurement.

This thread has been an incredible source of information - thank you for sharing!�

Apr 12, 2015

LargeHamCollider +1,

I'm interested to know the exact mass of one of the 16 battery modules from an 85, then we'd have independent measurements of capacity and mass and could get a very solid energy density number that isn't affected by the weight of the heavy shield on the bottom of the pack.�

Apr 16, 2015

Denys wk057, Could you please list the part number for the positive contactor? I'm trying to understand why they would use a different one from the negative side.�

Apr 17, 2015

arg Pure speculation: nothing to do with positive/negative per se, but one of the contactors needs to have breaking capacity to be opened under full load. The other one can be sequenced so that it only opens/closes under no load, and so can be smaller.�

Apr 17, 2015

wk057 I'll have to dig them out later and check. They're packed away right now.

This is actually a very probable explanation that I honestly hadn't even thought about... nice.�

Apr 17, 2015

FlasherZ This is probably right - it's a very, very remote chance your failsafe would need to be opened under load. The chance of your primary contactor welding closed along with the drivetrain experiencing a critical error requiring open-under-load simultaneously seems pretty remote. However, given Tesla's supply chain optimization, the question is whether that'll continue. I wonder what the spec difference is.�

Apr 17, 2015

glhs272 Does anybody have any good pictures of the 60kWh battery with the covers removed (including the hump) but not disassembled? I am curious of the feasibility of adding 2 more 60kWh type modules to the battery to make it a 70 (or a 60+ as I would call it). I am not saying I am going to do this, just wondering if it would be technically feasible. The additional modules would be wired in series with the existing modules which would make it operate at the same voltage as the 85kWh battery. This would significantly improve fast charging capability as well as make the 60 perform close to or better than the standard S85. Obviously some software details would have to be sorted out and the BMS board in the battery might not have available unused channels to talk to those new modules (assuming they used different hardware on the 60 vs. 85). I think it would be cool upgrade package if offered by Tesla. It would keep all of those 60 batteries on the road instead of having to take in used batteries in order for someone to upgrade. For those who have had their hands inside Tesla's batteries I think they would have a good feel if this idea has merit.�

Apr 19, 2015

TomE Maybe the coil wires are of different length?

Maybe the arc blow-out magnets are of differing polarities to help with packaging the DC bus bars by removing the need to arrange DC current to flow in a specific direction?�

Apr 22, 2015

thegruf Hi wk057, just found the battery wiki page on here.

http://www.teslamotorsclub.com/showwiki.php?title=Battery%20table&redirect=no

Looks like S85/P85/P85+ shared the same battery near enough.

May be just rolling upgrades, but from the latest results it does look like the P85D battery could be different (fuses?), and also the 85D is up-revved against all the others so could be just another variant or something altogether new?

Cue the new cells speculation, though imho I doubt it. Need a few mor recent reports eg 70D tbh.

Do you have any insight on this?�

Apr 22, 2015

wk057 My standing guess, until I see evidence to the contrary, is that the 70D simply uses 14 of the same modules used in the 85 pack (which uses 16) and they're just marketing it as the 70D instead of the 74.375D. This would just give it a hair extra buffer for low discharge vs the 60/85 which is fine.

It's possible the 70 pack could have 13 of the 85kWh type modules instead (12 in the back and one in the nose for balance) which would be 69.0625kWh... round up to 70 for marketing.

Either way, the only thing that makes sense is just switching to using the same modules as the 85kWh pack, since it eliminates the 60-type module, which has fewer cells, entirely. Streamlines pack production a bit more. Now the only choice will be 14 or 16 modules.

The P85, P85+, and S85 definitely have the same battery pack. The two packs I received were from an S85 and P85, and they were the same modules and same main pack fuse.

The P85D/85D packs likely have slightly larger main pack fuses and *maybe* slightly larger cell level fuses... but I doubt the latter now that I've tested the cell level fuses.

As for new cells, speculate all you want, but I'm guessing we won't see any new higher density cells until Model 3.�

Apr 22, 2015

thegruf Agree totally re 70D structure.

Curious that the last entry in the table (at the time of writing) ie the first 85D has a noticeably different pack nr though.

In theory this is just an 85KWh pack capable of same power as the other 85 models before it.

Would be interesting to see a teardown of a P85D pack to see which details are changed (if any), this would unfortunately mean a P85D write-off, so liely no volunteers!�

Apr 22, 2015

wk057 Well, unfortunately I'm personally pretty much done with tearing packs down. Two and a half packs should be enough for me. lol.

Definitely would also be interested if someone pops the cover on a P85D pack though.�

Apr 22, 2015

bwa Very extremely small nit: the "S" is probably a field name, so the serial # probably just starts with "T" (and may even be the first letter of the name of the company).�

Apr 22, 2015

hcsharp I'm having a hard time going with your 70kwh design theory. Fewer modules would require a re-designed charger, re-designed inverter, different BMS, and far more differences in firmware. There's a reason the 60 used the same number of modules. So many things rely on the voltage being the same across models. Tesla has already set a precedent with keeping the voltage the same across pack sizes. I see no reason why they would change that, and lots of reasons why they would go with the same number of modules in the 70, just fewer cells.�

Apr 23, 2015

llavalle Humm... The voltage is not the same on a 60 and a 85...�

Apr 23, 2015

JRP3 And I thought the 60 only used 14 modules instead of 16. I too assumed Tesla would keep voltages the same across all vehicles, but in fact they did not.�

Apr 23, 2015

scaesare The 60 pack does only have 14 modules. And it also has fewer cells in those 14 modules.�

Apr 23, 2015

WarpedOne Yes, so there are two venues toward 70kWh:

- 16 modules of those 'fewer-cell' modules (69kWh)

- 14 '85kWh-pack modules' (74kWh)

Part of the answer will be packs nominal voltage. If it stays at 350, it will say 14 modules. If it says 400V, it will mean 16 modules.

The other part of the equation will be weight - how will its mass relate to S60, S85 and S85D.

What doesn't ring right is why would tesla increase price of the battery for 16% (assuming same cells as in 85 just more of them) and only increase end price a tiny bit, reducing earnings / car.�

Apr 23, 2015

wk057 As others have already answered, the 60 didn't use the same number of modules as the 85kWh pack. It used 14 moudles for a nominal voltage of something like 302V. The 85kWh packs use 16 modules and have a nominal voltage of ~346V. The BMS is per module, also. So no changes needed there since the voltages are the same for both module types. Aside from that, the chargers can output a DC voltage from 50VDC to ~410VDC (can't recall the exact upper number off the top of my head). The 60 and the 85 share the same drive units, and they're rated to operate from a large voltage range (something like 200VDC to 425VDC).

So no real changes are needed besides just changing the modules.

I had considered the 16 of the 60-type modules as a solution, but it wouldn't have any real production advantage vs eliminating it.

I'm wanting to lean more towards the 13 module solution the more I think about it. 12 in rear, one in nose, 69kWh. Slightly lower nominal voltage and voltage range (280V nominal, ~327V charged, ~234V dead) but within spec of all of the other components. However, this would add a bit more complexity (new bus bar configuration in the pack vs just using the same ones from the 60 pack with 14 modules). So, not sure until I see a 70D supercharge voltage screenshot.

As for the price... in the absence of any verifiable data, I think everyone tends overestimates the battery cost to Tesla for some reason. Even using a high estimate like $400/kWh, adding 10kWh would be ~$4000. The cash price of the 70D is something like $6000 higher than the 60. So, I don't really think they're taking a hit.�

Apr 23, 2015

FlasherZ I don't think Tesla would make that decision anyway. They're not in that mode to cannibalize.�

Apr 23, 2015

scaesare The other option 16 of the "fewer cell" modules, but with less cells removed. Currently there are 64 cells in stead of 74 per group in the 'lite' modules... if they made this 65, it would add another ~1.1KW to a 16 module pack for a total of just over 70KW.

However, I'd agree with wk057 that simply standardizing on a single "full" module is the likely answer... even if that does mean the pack is slightly over it's advertised rating.�

Apr 23, 2015

stopcrazypp Right, if someone supercharges the 70D it'll be very easy to tell from the peak voltage how many modules it has. Just for reference:

60kWh 352V (14 modules in series *6 series group per module*4.19V)

85kWh 402V (16 modules in series *6 series group per module*4.19V)

Of course, that still doesn't tell how many cells is inside each module, but we can probably make a good guess depending on the module count.�

Apr 23, 2015

wk057 It should be pretty simple to interpolate the charging curves of the 60 and 85 packs for comparison to the 70D pack to come up with a pretty good guess on cell count.

Someone get a 70D to a supercharger and video it already!

Maybe one of you folks close to Fremont could go for a test drive...... to the Fremont supercharger.Even a single snapshot of the charge screen would at least get us the module count. hehe.

�

Apr 23, 2015

bxr140 I may have missed the apples to apples cart, but my 60 peaks at 361-362V when supercharging. If I extrapoate to 0% SOC it would be somewhere between 325 and 350.�

Apr 23, 2015

wk057 Not sure where 362 would come from, since that would be ~4.31V per cell using 14 modules...

The range for the 60 should be ~353 down to ~252 for 4.2V and 3.0V per cell respectively.�

Apr 23, 2015

hcsharp I didn't know that. I thought they had the same number of modules with fewer cells in each one. Sorry for taking things off-course.�

Apr 23, 2015

bxr140 <shrug>

Perhaps there's a sizable difference between charging voltage and pack voltage? I have no idea.�

Apr 23, 2015

wk057 It's possible. I've seen the supercharge voltage around 403-404V, which is a little high (2-3V) but I haven't seen it read 10V high... *shrugs*�

Apr 24, 2015

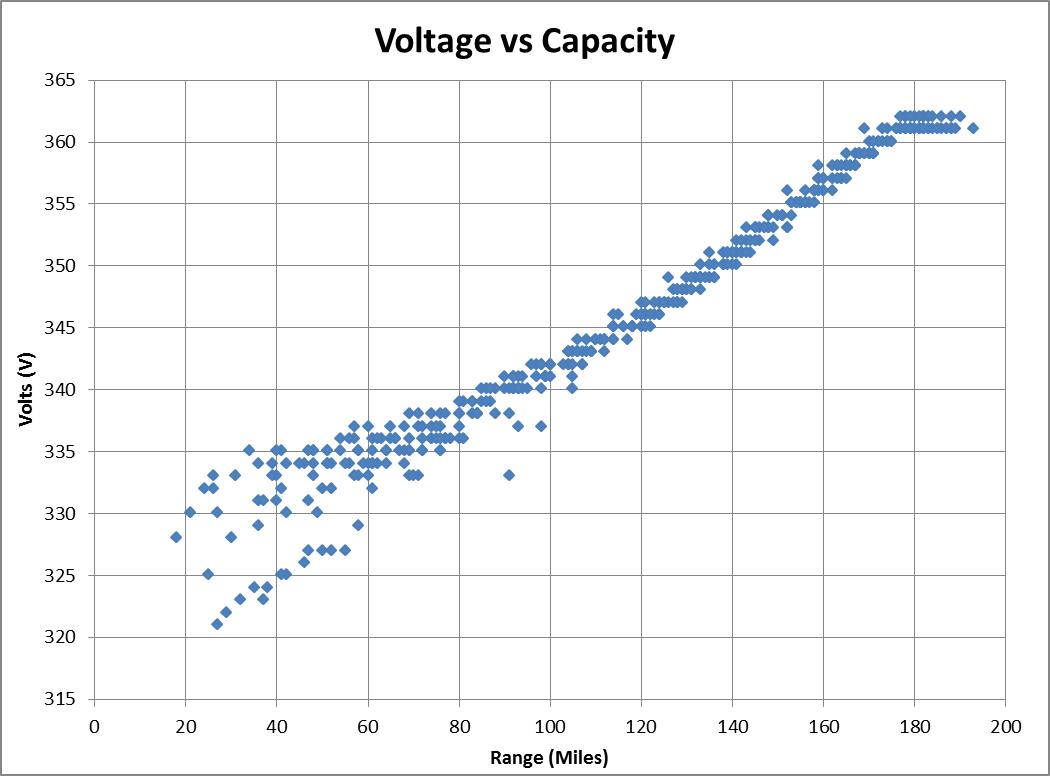

bxr140 Just to round out the dunno-what-to-do-with-this-data angle, here's what I've seen during charging. Of note:

--Charging voltage plateaus around 90% SOC. Could be some kind of balancing?

--Occasionally it bounces back and forth between 361 and 362. I don't think this is a significant piece of analysis.

--Points below the denser field are supercharger pairing events. I don't know enough about the hardware to speculate on the reason why this happens.

�

�

Apr 24, 2015

arg I think this is just the charging switching from being limited by the maximum current that the cells can take to being limited by the maximum voltage that they can take. This is normal behaviour for Lithium charging.

Also to be expected. The voltage at the terminals of the battery can be considered to be the actual standing voltage of the cells, plus the voltage dropped across the internal resistance of the cells and all the connecting wires by any current that is flowing (V=IR). So if you were able to measure the voltage of the idle pack at a given state of charge you would see figures a bit lower than your graph; in practice we only ever see voltage readings when charging is in progress, so the readings are higher than 'true' in proportion to the charging current.

When you are paired at a Supercharger you are getting less than the usual current, so the reading is lower than usual.�

Apr 24, 2015

yobigd20 can some rich folk with money spewing out their butt just buy a 60, a 70, an 85, and a new P85D and dissemble them all and check voltage and then count and let us know the answer so we can stop speculating?�

Apr 24, 2015

wk057 I'd be broke if I did that �

�

Apr 24, 2015

thegruf and speculating much more fun �

�

Apr 24, 2015

woof Perhaps query the guys on the investor's threads? You may have a better chance of finding said spewer there. But, if I had that particular predicament, I don't think I'd be sitting around (or able too!) reading these forums so chances are slim.�

Apr 24, 2015

stopcrazypp There are some cells that charge at 4.35V. If Tesla is using those it'll complicate things, but that difference is still not enough to account for a whole module (15 modules at 4.2V is already 378V), so the module count will still be 14.�

Apr 25, 2015

JRP3 What if the series cell count per module in the 60 is different than we are assuming?�

Apr 25, 2015

yobigd20 Wasn't a 60 battery pack disassembled by the NHSTA during their crash testing with pics posted online that proved less number of modules in the pack?�

Apr 25, 2015

scaesare Here's a pic. You can see the 10 blank spacers that make up two of the 6 parallel groups of cells that make up a complete module:

�

�

Apr 25, 2015

stopcrazypp As scaesare posted, we have disassembled pictures of the 60kWh module that show 6 groups in series. And we know from NHTSA pictures that there are 14 modules.

I can't really think of a reason to change the number in series per module, since keeping it the same allows them to use the same battery plate for all the different modules (just leave some cells blank per group, as with the 60kWh).

Also, if you assume 7 per module, that means 14*7*4.2V = 411V which is even higher. 13*7*4.2V = 382V, which is also higher. 12*7*4.2V = 353V but would be no different from at 14*6*4.2V assumption (which we have evidence of already).�

Apr 25, 2015

JRP3 Obviously we are missing something that explains why it looks as if Tesla is charging the 60 cells higher than the 85 cells. I would be very surprised if that were actually the case.�

May 3, 2015

gorgasyang wk057,

some information about tesla battery pack of this post have been reposted to chinese website.

sb areinterested to know the exact mass of the whole battery pack, although Tesla said the mass is 544kg.?a independent measurements is?very important for compare with other battery, i.e chinese BYD E6 and denza.

thx!?�

May 5, 2015

Otmar The value I heard from Tesla for a 85 kWh pack is 569kg (1254lb). I was glad to hear it was less than the 600kg that I read in some article, Car and Driver maybe?�

May 5, 2015

thegruf ..just trying to get additional information to rip off the Tesla battery .. dont feed them.�

May 22, 2015

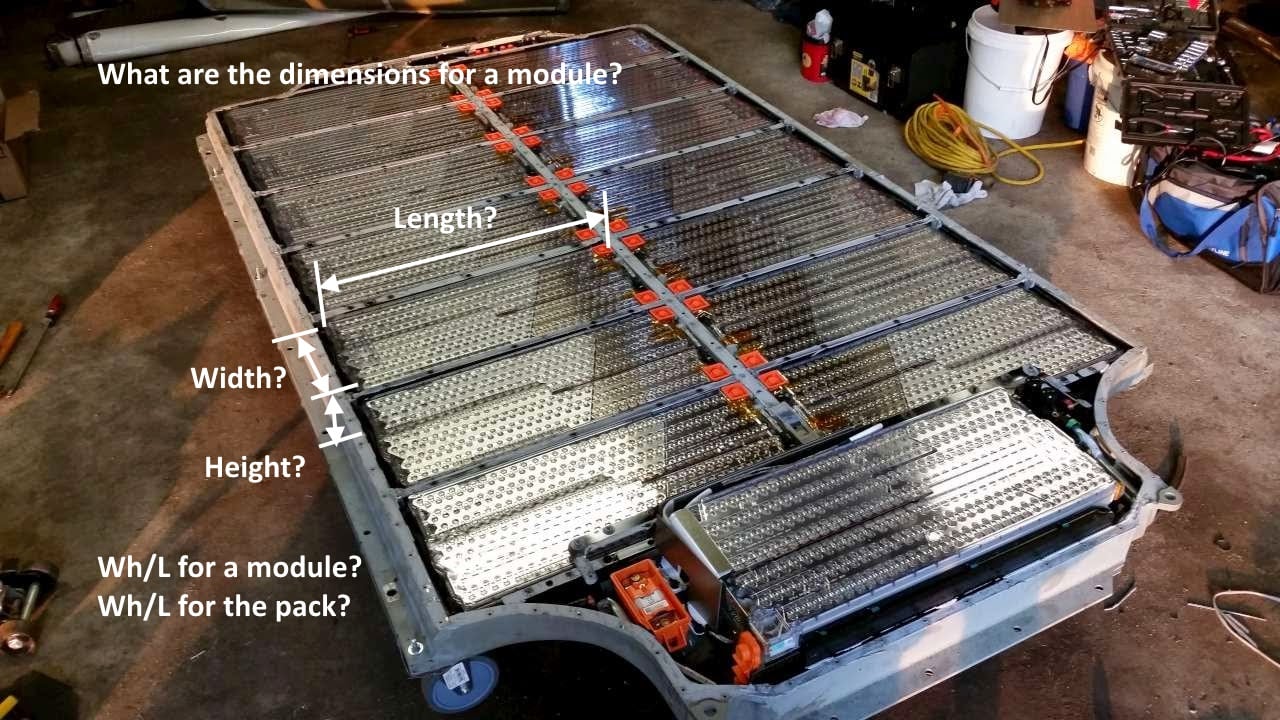

Bazinha Question: What are the dimensions for one of the Tesla Model S battery modules? See picture below. I would like to know the module Wh/L and pack Wh/L? �

�

May 22, 2015

tbader2 Also what is the max current and max voltage of each module?�

May 22, 2015

Johan Bahzina and tbader: both your questions have been thoroughly answered in this thread and in wk057's battery disassembly thread.�

May 22, 2015

Bazinha What is the module Wh/L and pack Wh/L?�

May 22, 2015

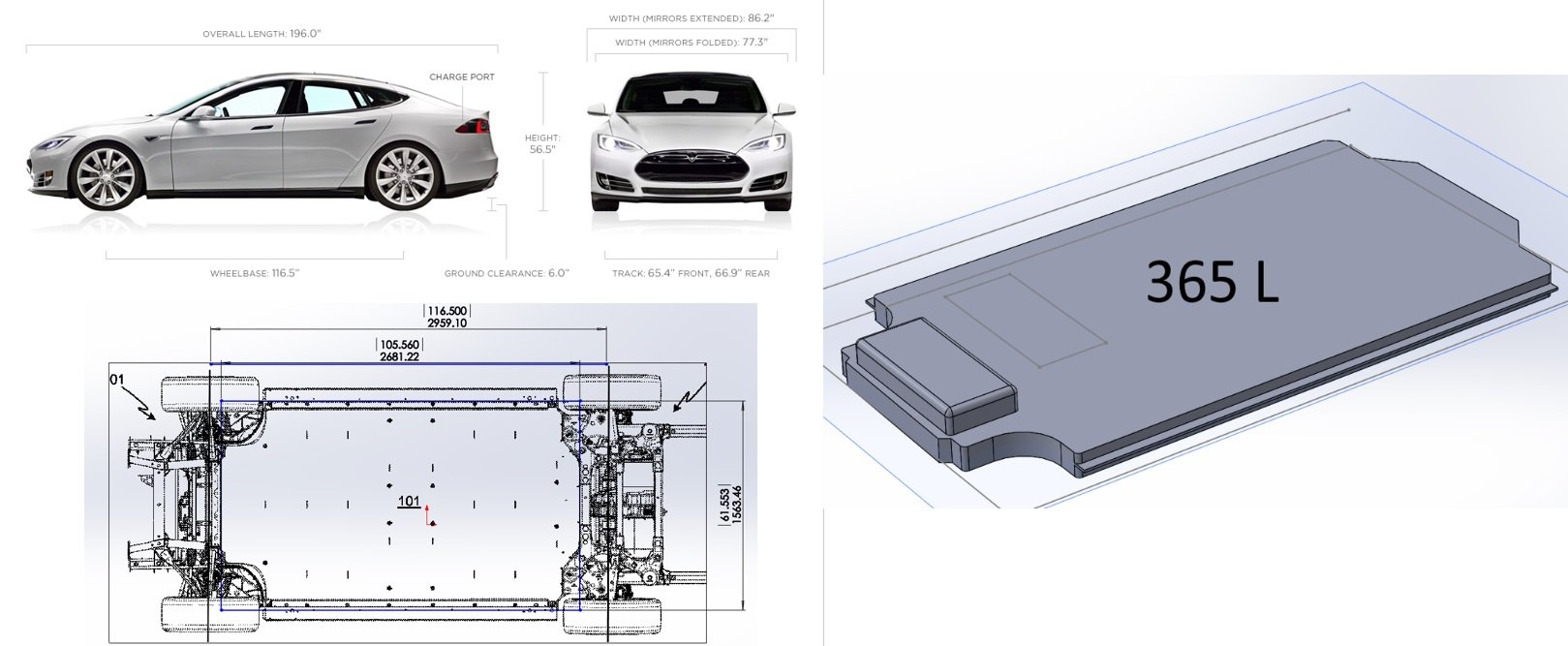

Bazinha I did a quick 3d modeling of the tesla pack based on the wheel base dimensions and patent drawings....and measured the pack volume to be ~ 365L which gives the pack --> 85 kWh/365L = 234 Wh/L ... Also if you assume a module to be 300x680x80 mm --> 16.32L --> 5.31 kWh/16.32 --> ~ 325 Wh/L. Can anyone confirm? Thanks!

�

�

May 28, 2015

Rory The BMS has limited capability to balance the pack using the bleed resistors of which there are 4 in parallel per cell block. On the picture R20,R21 & R22 are examples. They cannot dissipate much power say 2W total at a guess so may need to operate for longish periods.�

Jul 8, 2015

CHL

Don't forget that part of energy pushed in the pack during charge is lost in heat (internal resistance) during discharge.�

Jul 18, 2015

Pajda Exactly, Tesla uses passive cell balancing method based on dissipating balancing current via shunt resistors. In this particular case, we can see four 158 Ohm SMD resistors connected in paralel which gives us 39,5 Ohm total value.

We know that Cell chemistry used by Tesla has maximum charging voltage of 4,200V. So we can calculate, that maximum possible balancing current is Id = 4,200/39,5 = 106mA. Then we can calculate, that maximum dissipated power is Pd = 446mW and this power is divided between four small 0805? size SMD resistors, so there is no need for special cooling of these resistors.

So the point is, that Panasonic cells must have super tight production tolerance, so there is no need for high balancing currents (especially when compared to crappy LFP Winston cells). You should remember that there are always 74p 3400mAh cells which acts as one big ~251Ah cell and Tesla can balance them with only ~100mA current.

- - - Updated - - -

Thanks Bazinha, I think that your battery pack model is accurate enough. I was calculating this with dimensions wxhxl found in Tesla patents and my result was ~220Wh/l. If you appreciate, the battery pack info for other EVs batteries are:

VW e-UP!: 211 l / 230 kg / 18,7 kWh = 89 Wh/l and 81 Wh/kg

Kia Soul EV: 241 l / 275 kg / 27 kWh = 112 Wh/l and 98 Wh/kg

Chevy Spark EV(wit A123 cells): 139 l / 254 kg / 21,4 kWh = 154 Wh/l and 84 Wh/kg�

Jul 18, 2015

Pajda Thanks wk057 for your cell measurement. I assume that this discharge curve is quite OK. :smile: But I have a few hints or comments (sorry if they are well known for you)

Methodology: Did you use 4-wire (Kelvin) measuring method with your PL8 station? I mean bananas together with balancing connector?

For Coulomb counting (Ahr counter) it doesn't matter on the wire gauge which you use. You can use "nail" and still you got the same mAh capacity results with your PL8. (Because you make a series circuit and the discharge current is then the same in the whole circuit - so it doesn't matter where you dissipate the energy - inside the PL8, in the wires or in the Internal resistance of cell). The only thing which matters is how precise is your amperemeter in PL8 (it uses 16.bit ADCs so yes, we can consider the measurement as quite precise)

But the problem is with cell voltage measurement, which affected the measurement of total dissipated energy. There in 2-wire method the heavier wire gauge can help, but still there will be some influence (In fact you don't have problem with wire resistance, but with the contact resistance which is much harder problem to solve). So for precise cell voltage measurement is in Kelvin method used idependent voltmeter with high internal resistance and two independent wires (this method completely eliminates the influence of resistance of wiring).

Cell parameters:

Tesla uses NCA cells with 12Wh / 3350mAh nominal (11,7Wh / 3250mAh minimum for new cell), This minimum energy/capacity can be discharged below this test cycle:

Charge: 0,5C (1,625A) to 4,2V with cut off current C/50 (65mA)

Discharge: 0,2C (625mA) to cut off voltage 2,5V.

But we already know that Tesla doesn't allow you to brick the battery and also for initial production cell capacity variation so:

maximum pack usable energy is about ~81kWh (discharge to ~2,7V).

For "range driving" it is about ~75kWh (discharge to ~2,9V)

For "normal driving" it is about ~68kWh (discharge to ~3.1V).

For both driving modes you can discharge aditional ~5kWh as a zero mile protection.

______

Can you please measure a cell Internal Resistance with your PL8? (for this you definitely need the 4-wire method)�

Jul 20, 2015

Pajda I found in the shelf never used Panasonic NCR18650B (industrial grade equivalent to Tesla 12Wh cells). Cell was made in Q3/2013 and I do measurement under the upper mentioned test cycle: (charge: 1,65A to 4,2V with 65mA cut off, 15min rest time, then discharge: 620mA to 2,5V cut off) with these results:

Cell IR: 31,4 mOhms (this is DC resistance measured by PL8 algorithm which is not so precise, anyway manufacturer specs say that it should be less than 45mOhms)

cell cut off voltage - cell measured capacity - cell measured energy - pack energy (x7104 cells for 85kWh pack) - pack cut off voltage (x96 for 85kWh pack)

2,5V - 3268mAh - 11,75Wh - 83,49 kWh - 240 V

2,7V - 3244mAh - 11,69Wh - 83,05 kWh - 259 V

2,9V - 3209mAh - 11,58Wh - 82,25 kWh - 278 V

3,0V - 3172mAh - 11,49Wh - 81,61 kWh - 288 V

3,1V - 3120mAh - 11,33Wh - 80,49 kWh - 297 V

3,2V - 3036mAh - 11,07Wh - 78,63 kWh - 307 V

3,3V - 2883mAh - 10,58Wh - 75,13 kWh - 317 V

3,4V - 2664mAh - 9,85Wh - 69,97 kWh - 326 V

3,5V - 2308mAh - 8,64Wh - 61,35 kWh - 336 V

You can see that there is no magic in Tesla pack in the term of 85 kWh energy rating.

By the way this sample losses minimum energy due to almost 2 year of storage and still it is above minimum capacity (3250mAh). This cell is an older version "B" with graphite only anode, cells made in 2014 are marked as "BF" and it uses SiO aditive to graphite Anode. Here you can see the datasheet https://www.akkuteile.de/tpl/download/NCR-18650BF.pdf which shows the main differences. The SiO aditive improve almost all parametrs of NCA cells, but the most important improvement is in the power and cycle life region, not the energy density. I think, that Tesla already uses this SiO cells equvalent for the whole 2014.

The new 90kWh pack cells are for sure with SiO additive, but i think that the increase of capacity is not caused by SiO itself. This cells are most probably rated as 12,6Wh/3500mAh nominal and 12,2Wh/3400mAh minimum for new cell. We can see their industrial equivalents from LG, Samsung and Sanyo.�

Sep 12, 2015

apacheguy @wk057 - Any idea how well these modules buffer temperature changes with coolant present in the lines? I'm curious how well a standing module does while it's sitting out in my driveway. Could be a neat experiment to try to model the environment of the cell resting in the main pack and have two temp sensors - one on an individual cell and another ambient and make a plot of the two.�

Sep 12, 2015

Ingineer I think wk057 is off the forum until further notice.�

Sep 12, 2015

apacheguy Yeah. Thought he said he was still maintaining this thread tho.

Oh, but wait. Since you somehow have access to the cars logs you can answer this question without us have to go to the trouble of doing an experiment. Can you make a plot of module temp v ambient on one of these hot days? That'd be really great.�

Sep 12, 2015

wk057 Actually, I'm keeping an eye on my project threads and technical threads like this one. Just staying out of the nonsense.

I haven't messed around much with the coolant loop just yet. The cells I have installed in my rack are in a room that is temperature controlled to 64F, and even under maximum load or charge for my system the ambient air is enough to keep them under 70F.

The modules DO have two temperature sensors each. One is on a cell close to the inlet of the cooling loop, and the other is on a cell close to the outlet of the cooling loop. So, the temperature data is available to the car at least, and I'm going to use these sensors in my custom BMS (they're just 10k thermistors).�

Sep 14, 2015

JST I know this is OT for the thread, but as someone who's dug perhaps more than anyone else into the nuts and bolts of the Tesla pack, any thoughts on Porsche's proposal to use an 800V pack? Does this say anything particularly interesting about the technology they're planning to use?

Porsche annnounces BEV version of 911 -�

Sep 14, 2015

Scotty Although I have no experience with the Tesla pack, I do with EV's. I've done an EV upgrade from VRLA gel batteries ti LiFePO4 battery packs, and there are advantages and disadvantages to higher voltage battery packs. My upgrade is from a 72 Volt Nominal system to an 80 Volt nominal system, and even that small increase is noticeable.

Here's some info.

At a certain load, the motor and motor controller use a set amount of power. Assuming the system can handle higher voltage (which could be simple or compex), the following applies

Increasing the voltage will decrease the current drawn, when delivering the same amount of power

Current through a resistance generates heat, which is fine for a toaster, but not so fine for motors and lighting

Since increasing voltage decreases current, at higher voltages. less heating at the same power point will occurr

Since current through the resistance decreases, smaller diameter conductors can be used, decreasing weight and cost of the cables

Charging a higher voltage pack may be more complicated and/or expensive I.E. charging an 800 Volt pack will requires much higher rated components/assembles than 400V.

-- However, dividing the pack into modules will allow for optimized and independent module charging, which is dependent on individual module monitoring and control

Higher voltages can be more efficient.

Other assemblies in the vehicle can be more costly i.e higher voltage DC/DC Converters to switch 800 VDC to 13 Volt DC for ancillary equipment... lights, displays, etc

Current chargers already incorporates more efficient design, but higher voltages bring more expense in design, fabrication and component / assembly specifications

DC Battery pack feeds DC high voltage, high current to Motor controller, which then converts and controls it's output, which is 3 phase power to the AC Motor.

The design and integration of the AC Motor Controller to the 3 Phase AC Induction Motor is complex and complicated, in itself (Look at the Tesla MS Motor Controller in the How It's made Youtube Video to see it).

Scotty�

Sep 14, 2015

wk057 800V is a whole different ball game. Different wire insulation requirements, DC arc arresting, etc. Good luck finding a reasonably priced high current 800V DC contactor.

An advantage would be that the higher voltage would allow higher power at lower currents, if the pack could handle it. But voltage alone doesn't really tell us a whole lot.

Plus, I don't believe any existing charging standard supports 800VDC. So, I'm thinking someone typod this, honestly. It's likely be way more trouble than it's worth to go above ~500V.�

Sep 14, 2015

lolachampcar Not to mention IGBTs for 800 Vdc working :0�

Sep 14, 2015

JRP3 I thought 800V sounded a bit high, but, at least for industrial motors, up to 13,200 Volts seems to be labeled "medium voltage"http://www.esrmotors.com/Motors-Medium_Voltage.html

�

Không có nhận xét nào:

Đăng nhận xét